What is 5754 Aluminum Alloy?

5754 is part of the Al-Mg series (5xxx series) of non-heat-treatable aluminum alloys, known for their excellent corrosion resistance and moderate-to-high strength developed through cold working. With outstanding weldability and formability, 5754 is one of the preferred lightweight alloys for marine construction—ideal for hulls, decks, bulkheads, and structural marine components.

This alloy is available in a wide range of tempers including O (soft annealed), H111, H22, H24, H26, H114, H12, H14, H16, H18, H32, H34, H36, and H38. Notably, H114 and H111 are commonly used for tread plate applications.

Specifications

5754 Marine Aluminum Alloy — Specifications

Tempers: O, H22, H32, H34, H36, H38, H111, H112, etc.

Plate Size Range: Thickness 3–50mm × Width 500–2600mm × Length 500–16000mm

Pipe/Rod Range: Outer diameter Φ1–17,000mm, custom lengths up to 20m

Classification Certificates: BV, DNV, ABS, Lloyd’s, Lioyds Register available upon request

Mechanical Properties in Various Tempers

| Temper | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) |

| O | 190-240 | ≥80 | ≥12 |

| H32 | 240-280 | 190-220 | 10-15 |

| H34 | 260-300 | 210-240 | 8-12 |

| H111 | 260-330 | ≥190 | ≥8 |

Detailed Mechanical Properties by Temper

| Temper | Thickness [mm] | Yield Strength (Rp0.2 N/mm²) | Tensile Strength (Rm N/mm²) | Elongation (%) | Hardness (HB) |

| O / H111 | >0.2-100.0 | ≥80 | 190-240 | ≥12 to ≥18 | 52 |

| H112 | ≥6.0-80.0 | ≥80-100 | ≥190 | ≥10-14 | 52-62 |

| >0.2-40.0 | ≥170 | 220-270 | ≥4-9 | 66 | |

| H14 | >0.2-25.0 | ≥190 | 240-280 | ≥3-6 | 72 |

| H16 | >0.2-6.0 | ≥205-220 | 265-305 | ≥2-3 | 80 |

| H18 | >0.2-3.0 | ≥250 | ≥290 | ≥1-20 | 88 |

| H22 / H32 | >0.2-40.0 | ≥130 | 220-270 | ≥7-11 | 63 |

| H24 / H34 | >0.2-25.0 | ≥160 | 240-280 | ≥6-10 | 70 |

| H26 / H36 | >0.2-6.0 | ≥190 | 265-305 | ≥4-6 | 78 |

| H28 / H38 | >0.2-3.0 | ≥230 | ≥290 | ≥3-4 | 87 |

Physical and Electrical Properties

| Property | Value |

| Density | 2.66-2.67 g/cm³ |

| Solidus Temperature | ~600°C |

| Liquidus Temperature | ~650°C |

| Thermal Conductivity | 130-160 W/m·K |

| Coefficient of Thermal Expansion | 23.7–24 × 10⁻⁶ /K |

| Electrical Resistivity | 0.049 × 10⁻⁶ Ω·m |

| Electrical Conductivity | ~33% IACS |

| Elastic Modulus | 68–70.5 GPa |

| Specific Heat | 900 J/kg·K |

Chemical Composition (%)

| Element | Al | Mg | Mn | Fe | Si | Cr | Zn | Cu | Ti | Others (each) | Others (total) |

| Content (%) | 94.2–97.4 | 2.60–3.60 | ≤ 0.50 | ≤ 0.40 | ≤ 0.40 | ≤ 0.30 | ≤ 0.20 | ≤ 0.10 | ≤ 0.15 | ≤ 0.05 | ≤ 0.15 |

Core Advantages

Key Advantages of 5754 Marine Aluminum

1. Outstanding Seawater Corrosion Resistance

5754 exhibits stable performance in saline, high-humidity environments, effectively resisting chloride-induced corrosion—greatly enhancing ship lifespan and reducing maintenance costs.

2. Excellent Weldability

Compatible with multiple welding processes (MIG, TIG, etc.) and produces strong, crack-resistant joints—ideal for large marine structure assembly and repair.

3. Superior Formability & Machinability

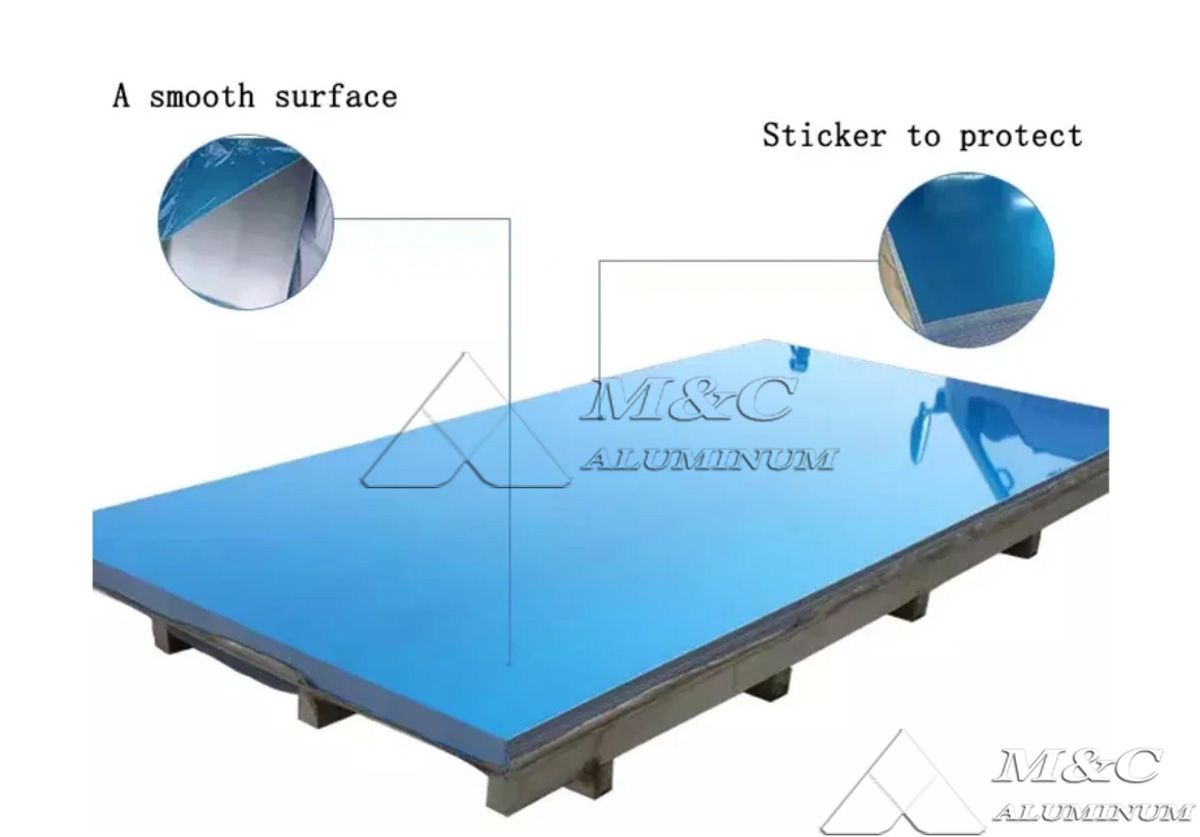

Performs exceptionally in bending, stamping, cutting, and forming operations—enabling complex hull designs with smooth, high-finish surfaces.

4. Medium Strength & Lightweight Efficiency

At approximately one-third the density of steel, 5754 provides significant weight reduction while maintaining structural strength—enhancing fuel economy and load capacity.

Applications

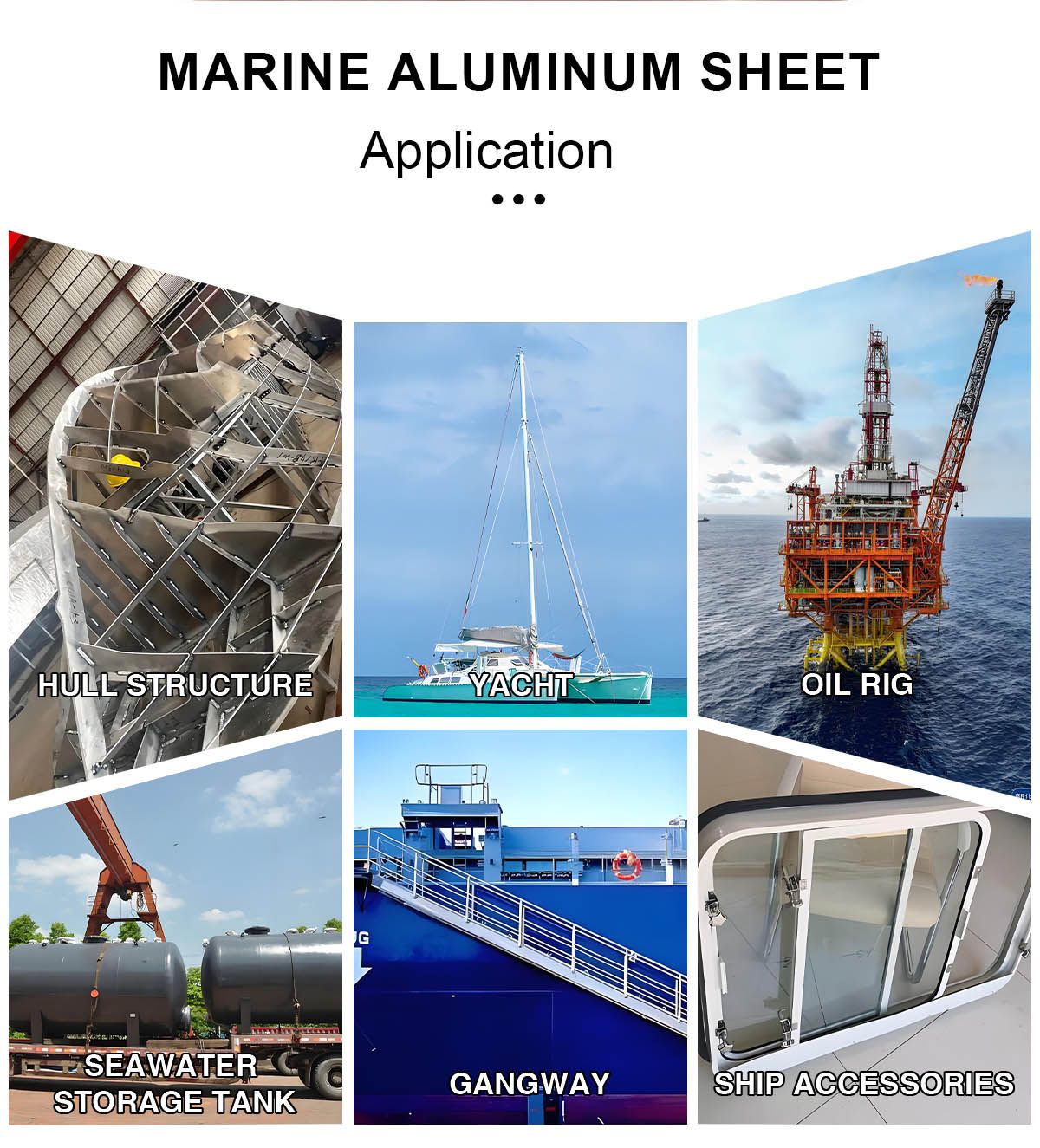

Applications of 5754 Marine Grade Aluminum

Hull plates, decks, and cabin interior walls

Offshore platforms and floating bridge components

Lightweight boat frames for yachts, fishing vessels, passenger ferries

Speedboat floors, fenders, hatch covers, and marine fittings

Contrast

5754 Compared to Other Marine Alloys

(1)5754 vs 5083

Magnesium: 5083 has higher Mg content (~4.5%) than 5754 (~3%), resulting in greater strength.

Strength: 5083 is stronger and harder than 5754.

Formability: 5754 offers better formability in medium-strength applications.

Use Case:

5754: Storage tanks, marine panels, car parts, pressure vessels

5083: High-load marine components, cryogenic vessels, defense-grade structures

(2)5754 vs 5052

Magnesium: 5754 has more Mg than 5052.

Strength: 5754 is stronger than 5052.

Cost: 5052 is more economical.

Use Case:

5052: Fuel tanks, marine hardware, medium-duty vessels

5754: Slightly higher strength and durability for structural parts

(3)5754 vs 6061

Series: 5754 (non-heat-treatable), 6061 (heat-treatable)

Strength: 6061-T6 is stronger, but 5754 is more corrosion resistant

Weldability: 5754 has excellent weldability with minimal strength loss; 6061 may require post-weld heat treatment

Marine Use:

5754: Ideal for parts exposed to seawater

6061: Better for structural brackets, masts, and machining parts, less ideal for constant saltwater exposure

Quality

Strict Quality Control for Marine-Grade Certification

(1)Visual Inspection

No cracks, corrosion spots, nitric acid marks. Minor surface defects are allowed within defined limits:

Max depth ≤ 0.5mm

Total affected area ≤ 5% of total sheet area

(2)Mechanical Performance

Tensile Strength (σb): 165–265 MPa — balancing structural demands and fabrication ease.

(3)Compliance Standards

All mechanical, dimensional, and surface standards comply with major international marine aluminum certifications such as ISO, EN, ASTM B209, and classification society specifications.

Choose US

Why Choose MC Aluminum?

Customizable sizes, thicknesses, and tempers

Full quality assurance with multi-stage inspection

Rich experience in serving global shipyards

Fast delivery and support for both bulk & small-lot orders