6061 aluminum flat bar is a solid rectangular extruded aluminum bar that is easy to machine and has a wide range of applications. Thanks to its lightweight nature and excellent corrosion resistance, aluminum flat bar is widely used in projects that require both durability and weight reduction. With reliable strength, it is the preferred material for structural components, shipbuilding, and automotive applications.

6061 T6 Aluminum Alloy in Shipbuilding

6061 T6 aluminum alloy, with its high strength, corrosion resistance, lightweight properties, and excellent machinability, is widely applied in ship superstructures, high-speed hulls, deck structures, piping systems, and auxiliary equipment.

6061 T6 Temper

The “T6” temper is achieved through solution heat treatment and artificial aging, providing 6061 aluminum flat bar with maximum strength and hardness, making it ideal for structural applications. In marine environments, 6061 T6 exhibits excellent fatigue resistance, making it suitable for hull structures subjected to high-frequency vibration.

Compared with 5000 series alloys (such as 5083), 6061 T6 has slightly lower corrosion resistance but higher strength, making it suitable for superstructures not in direct contact with seawater. Compared with 7000 series alloys (such as 7075), it has superior stress corrosion resistance and a wider range of applications.

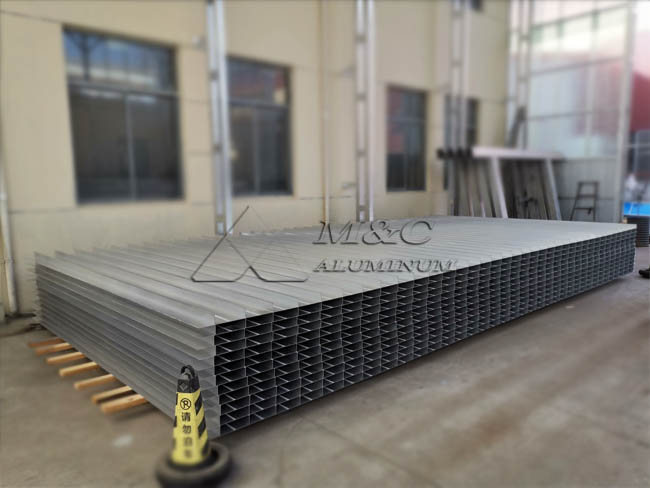

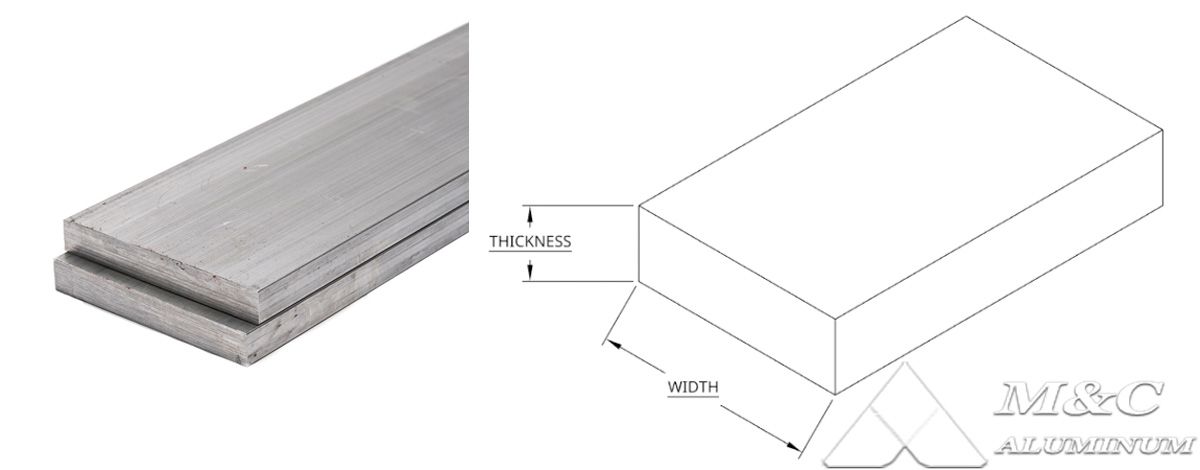

Specifications of 6061 Aluminum Flat Bar

| Equivalent Names | A96061, EN AW-6061, Al-Mg-Si-Cu, HE20, AA6061, 3.3211 |

| Tempers | T6, T651, T6511 |

| Thickness | 0.08 in – 9.8 in (2 – 250 mm) |

| Width | 0.2 in – 11.8 in (5 – 300 mm) |

| Length | 3m / 6m / 12m, custom cutting available |

| Edge Options | Square edge, rounded edge, R-chamfer |

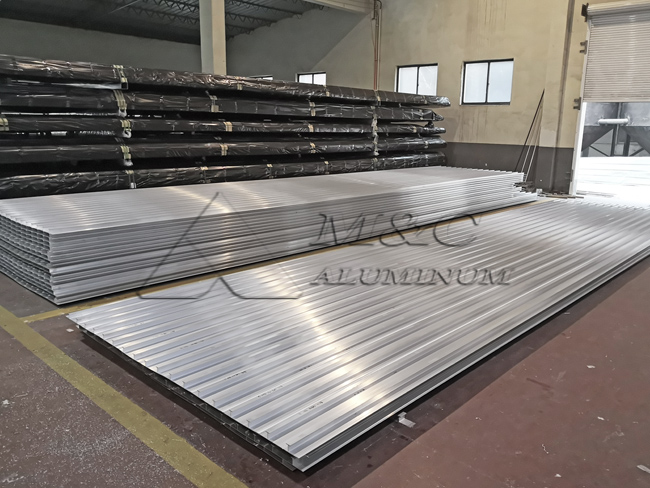

| Production Process | Extrusion, aluminum plate sawing |

| MOQ | 1-3 tons |

Mechanical Properties

| Alloy | 6061-T6 |

| Tensile Strength | 270–310 MPa |

| Shear Strength | 210 MPa |

| Elastic Modulus | 69 GPa |

| Brinell Hardness | 93 |

| Elongation at Break | 10% |

Key Features of 6061 Marine Aluminum Flat Bar

1.Excellent Strength-to-Weight Ratio: Provides reliable structural support while remaining lightweight.

2.Outstanding Corrosion Resistance: Performs well in both atmospheric and marine environments.

3.Good Fabrication Properties: Offers excellent weldability and cold formability, easy to cut, bend, and fabricate.

4.Superior Machinability: Supports efficient cutting with smooth surface finishes.

5.Heat-Treatable: Strength and hardness can be significantly enhanced through processes such as T6 temper.

6.Surface Treatment Versatility: Responds well to anodizing, electroplating, and coating, enhancing both durability and aesthetics.

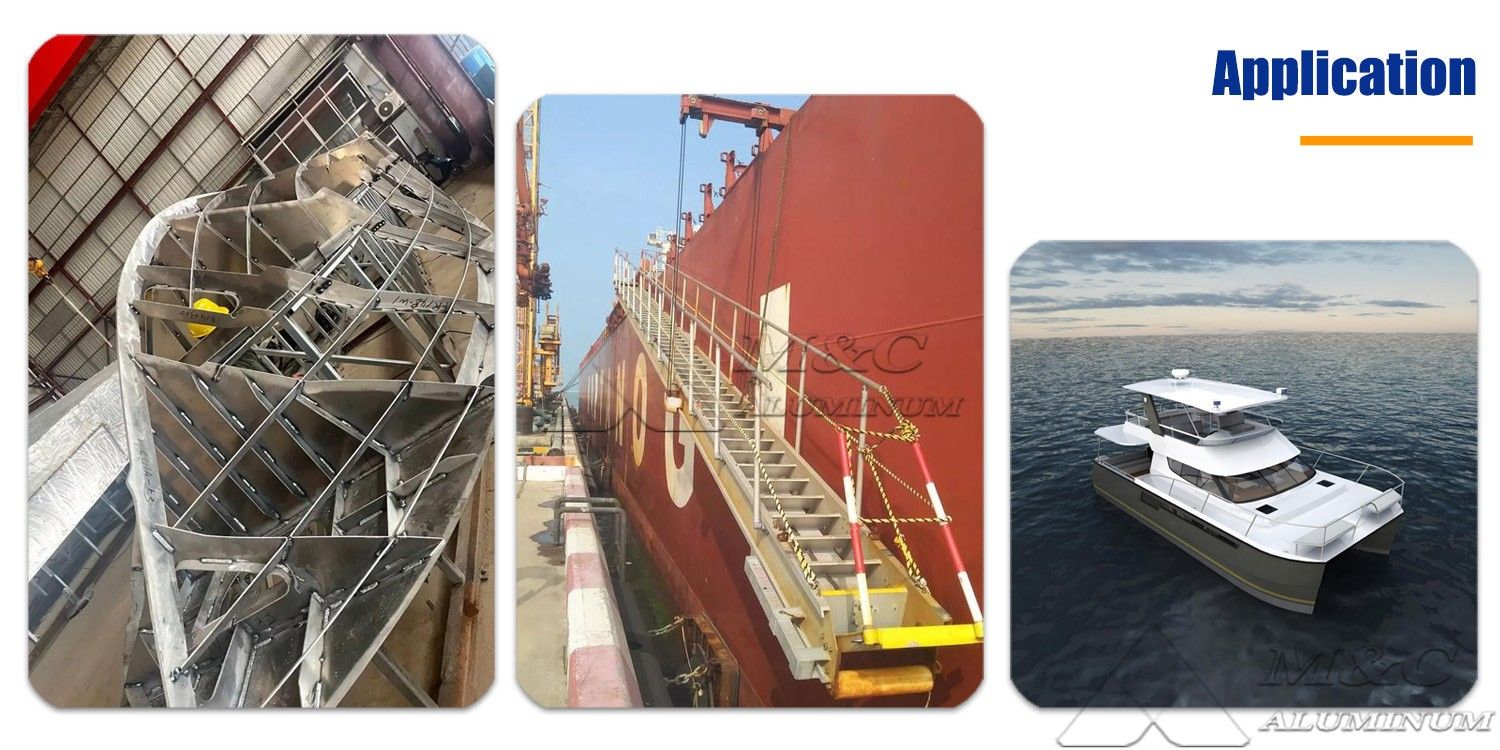

Applications of 6061 Flat Aluminum

Hull Frames & Reinforcements: Provides strength and weight reduction for load-bearing components.

Deck & Cabin Structures: Used in deck edge reinforcement and bulkhead supports, enhancing rigidity.

Gangways & Railings: Lightweight and corrosion-resistant, ideal for ladders, handrails, and guardrails.

Outfitting Components: Applied in brackets, fasteners, rails, and drainage systems.

High-Speed Vessels & Yachts: Its lightweight advantage improves speed and fuel efficiency.

Surface Treatment Options for 6061 Aluminum Flat Bar

MC Aluminum offers various surface finishing options, including:

Polishing: For a bright, glossy finish.

Anodizing: Enhances corrosion resistance and offers a variety of colors.

Sandblasting: Provides a uniform matte or textured surface.

We are committed to delivering high-quality, professional solutions tailored to your project needs.

Common Fabrication Services for 6061 Aluminum Flat Bar

To meet customized production requirements, manufacturers often provide:

Precision Cutting: Fixed-length and special-shape cutting per customer drawings.

CNC Machining: Milling, drilling, slotting, threading, etc.

Bending & Forming: For customized structural and frame components.

Edge Smoothing: Deburring and chamfering for smooth, safe, and aesthetic edges.

Welding & Assembly: For ship structures and mechanical parts.

Heat Treatment: Options such as T4, T6 to meet different strength and toughness requirements.

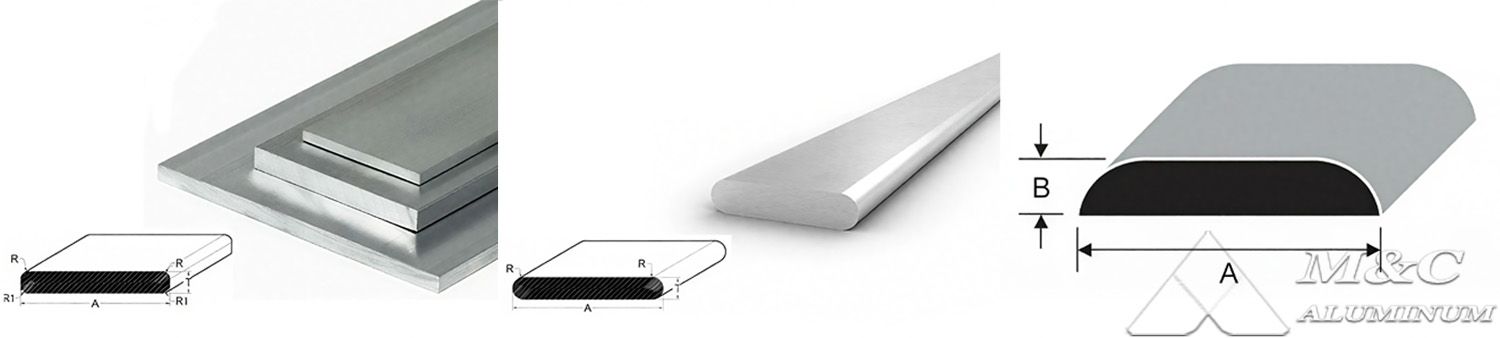

Edge Processing Types of 6061 Aluminum Flat Bar

Flat End Type

Produced by direct extrusion or precision cutting, both ends remain square without rounded corners. This type offers high dimensional accuracy and stable geometry, ideal for applications with strict tolerance requirements, such as precision assembly, structural supports, aerospace parts, and mold making.

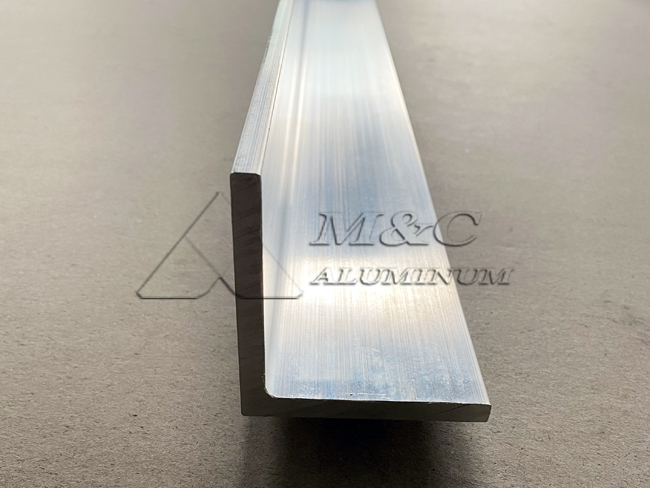

Rounded Edge Type

Features rounded transitions at the edges, effectively reducing stress concentration and improving fatigue resistance. Suitable for aerospace parts, racing chassis, and heavy machinery frames that endure cyclic loads and vibrations.

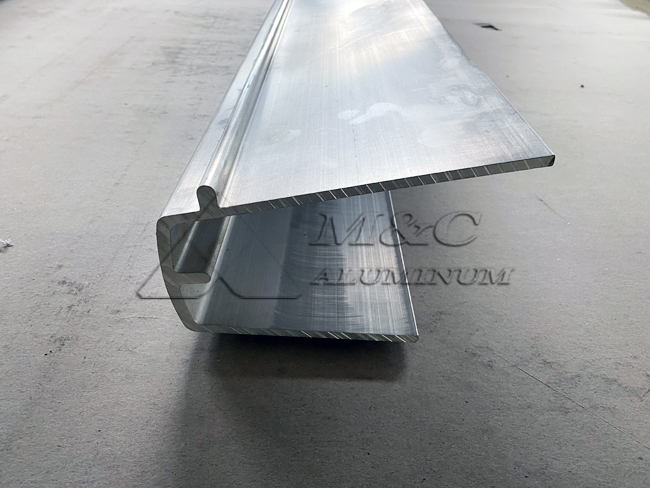

Double-Feathered Edge Type

This type adopts a double-tapered edge design, ensuring uniform stress distribution while optimizing fluid dynamics. It enhances mechanical performance and reduces the need for post-processing. Its lightweight and precision make it ideal for sports equipment, aerodynamic components, and high-performance precision applications.

Original Source: https://www.marinealum.com/a/6061-t6-aluminum-flat-bar-for-shipbuilding.html

Tag: 6061 Aluminum Flat Bar 6061 Flat Bar 6061 Extruded Aluminum Flat Bar 6061 Marine Aluminum Flat Bar 6061 Flat Aluminum Marine Grade Aluminum Flat Bar Marine Flat Bar 6061 T6 Aluminum Profile 5083 Aluminum Flat Bar Aluminum Profiles Extruded Alumi