Why 6061 T6511 Aluminum Flat Bar for Marine Applications?

Thanks to its excellent overall performance, 6061 T6511 aluminum flat bar plays an important role in shipbuilding and marine repairs. It offers medium strength, outstanding corrosion resistance (especially in atmospheric and seawater environments), good weldability, and excellent machinability.

Its high strength-to-weight ratio is particularly advantageous in the marine industry, helping reduce vessel weight, improve performance, or increase load capacity.

What is 6061 T6511 Aluminum Alloy?

6061 belongs to the 6xxx series aluminum-magnesium-silicon alloys. Its primary alloying elements are magnesium (Mg) and silicon (Si). After heat treatment, it demonstrates good mechanical strength and corrosion resistance.

T6511 temper means the material has undergone solution heat treatment, artificial aging, and stress relief, resulting in more stable mechanical properties and improved dimensional accuracy.

Compared with T6, T6511 temper includes a stretching and straightening process after extrusion, which reduces residual stress. This makes it particularly suitable for precision machining and marine structural applications.

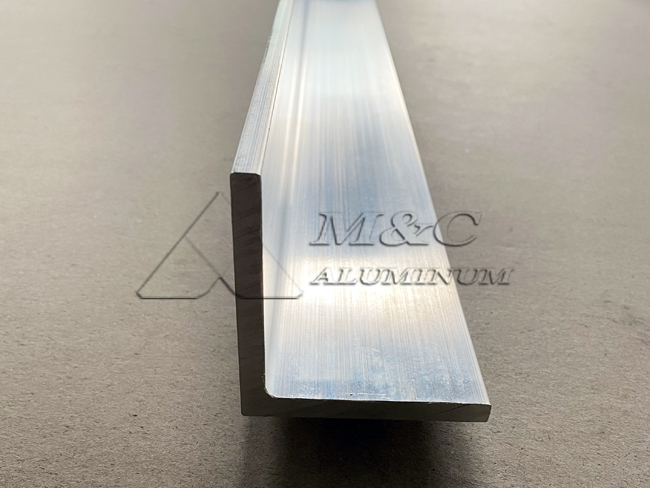

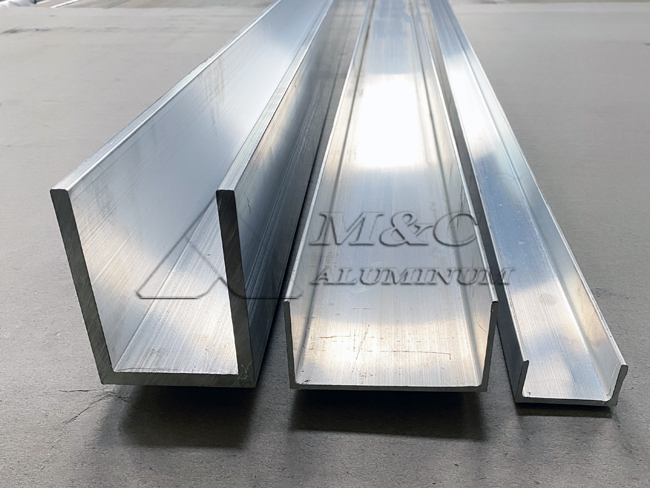

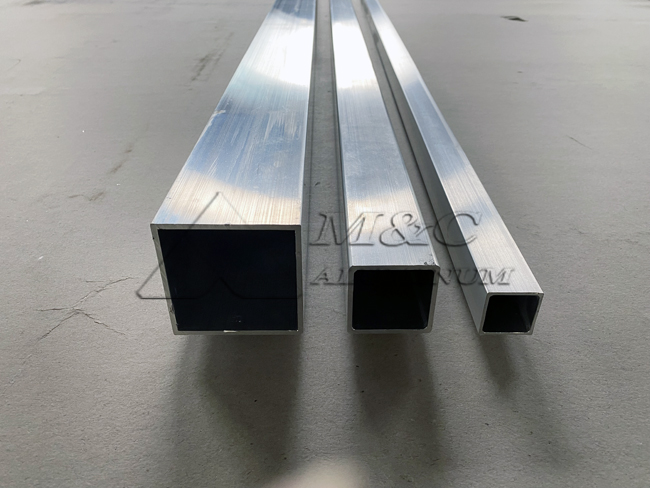

6061 T6511 Flat Bar Product Information

| Alloy | 6061 |

| Temper | T6511 |

| Shape | Aluminum flat bar |

| Thickness range | 6 mm - 200 mm |

| Width range | 20 mm - 500 mm |

| Length | Fixed or custom (standard 2 m - 6 m) |

| Tensile strength | ≥ 310 MPa |

| Yield strength | ≥ 276 MPa |

| Elongation | ≥ 12% |

| Density | 2.70 g/cm³ |

Key Features of 6061 Marine Grade Flat Bar

1. Excellent Corrosion Resistance

Performs well in seawater and high-salinity environments, ideal for marine contact parts.

2. Balanced Strength and Toughness

Although its strength is slightly lower than 7xxx alloys, it offers high tensile strength and good ductility to withstand wave impact and long-term loads.

3. Good Weldability and Machinability

Supports MIG, TIG, and other welding methods with reliable joint performance. The flat bar has a smooth surface, easy for machining and surface treatments.

4. Lightweight

With only one-third the density of steel, 6061 helps reduce vessel weight, improve speed, and cut fuel consumption.

5. Low Residual Stress

T6511 temper undergoes stretching and straightening, minimizing residual stress. This reduces deformation during machining and ensures high assembly accuracy.

Applications of Marine Aluminum Flat Bar

Structural supports: Hull frames, longitudinal and transverse beams for structural strength and stability.

Equipment brackets: Mounting for navigation, communication, and electrical devices.

Protective and decorative parts: Handrails, guardrails, decks, and ladders.

Marine equipment: Cabin doors, window frames, and lightweight but durable fittings.

Comparison with Other Aluminum Alloys in Shipbuilding

5052/H32: Superior corrosion resistance and formability but lower strength than 6061-T6511. Commonly used in hull plates and hatches.

5083/H116/H321: A classic marine alloy with excellent seawater corrosion resistance and weldability, offering higher strength than 5052. Widely used in primary ship structures.

6063: Excellent extrusion performance, mainly for decorative parts and windows. Lower strength compared to 6061.

Surface Treatment & Machining Options

6061 T6511 aluminum flat bar can be processed with:

Anodizing: Improves corrosion resistance and decorative appearance.

Spray coating or anti-corrosion coating: For long-term seawater immersion.

Precision machining: Suitable for high-strength structural components and custom marine fittings.

Original Source: https://www.marinealum.com/a/6061-t6511-marine-grade-aluminum-flat-bar.html

Tag: 6061 T6511 flat bar 6061 aluminum flat bar 6061 flat bar 6061 extruded aluminum flat bar 6061 marine aluminum flat bar 6061 bar marine grade aluminum flat bar marine aluminum flat bar 6061 T6511 aluminum profiles 6061-T6 aluminum flat bar 5083 a