As a high-magnesium marine-grade aluminum alloy, 5456 is widely used in naval vessels, oil tankers, floating bridges, and container ship hulls due to its excellent strength and marine corrosion resistance. However, even the best material requires reliable joining techniques—weldability compatibility is key to applying 5456 aluminum in real-world engineering.

Welding Methods for 5456 Marine Aluminum

TIG/MIG Welding (Gas Tungsten/Metal Arc Welding): Suitable for thin plates and high-precision welding. Argon shielding reduces oxidation defects and results in aesthetically pleasing weld seams.

GMAW (Gas Metal Arc Welding): Ideal for thick plate welding. Offers high efficiency, but heat input must be controlled to prevent hot cracking.

Friction Stir Welding (FSW): As a solid-state welding method, FSW is suitable for high-strength aluminum alloys sensitive to heat. It minimizes porosity and oxide inclusions (refer to similar aluminum alloy experiences, such as the FSW process optimization for 6005A-T4).

Recommended Welding Wire Selection

General Use: 5356 aluminum-magnesium welding wire is recommended due to its high compatibility with the base metal, offering good strength and crack resistance—especially suitable for welding 5xxx-series high-magnesium aluminum alloys.

Special Requirements: For higher strength or corrosion resistance needs, 5554 or 5183 welding wires may be used. For example, in shipbuilding, 5554 wire with higher magnesium content is often selected to enhance corrosion resistance against seawater.

Pre-Welding Cleaning: Surface oxide films (typically around 5 μm thick) must be thoroughly removed. Otherwise, oxide particles (e.g., Al₂O₃) can form weak joints during welding, significantly reducing joint strength.

Welding Compatibility of 5456 Aluminum with Other Alloys

1. With Other Al-Mg Alloys (5xxx Series):

With 5083/5086 Aluminum: Best compatibility due to similar magnesium content and matched thermal expansion coefficients and corrosion resistance. Recommended wires include 5356 or 5554. Strength retention can exceed 80% of base material. For example, 5456 and 5086 are commonly used together in upper structures of ships, and using 5356 wire with pulsed MIG welding helps avoid hot cracks and ensures seawater corrosion resistance.

With 5052 Aluminum: Attention must be paid to magnesium content differences. 5356 wire compensates for Mg loss. To avoid hot cracking, reduce heat input. Recommended welding current: 90–120 A; speed: 40–60 mm/min. Joint strength can reach over 85% of the base metal.

2. With Other Aluminum Series:

With 6061 Aluminum: Care must be taken to avoid silicon migration. Use low-silicon 4043 wire to suppress the formation of brittle Mg₂Si phases, thus improving weld ductility. Optimize TIG welding parameters (current: 140–160 A) and consider double-pulse processes to reduce defects.

With 7075 Aluminum: Use friction stir welding (FSW) with parameters of 1200–1300 rpm and a welding speed of 700–800 mm/min. This reduces heat input and preserves the age-hardening effect of 7075-T6. Joint strength coefficient can reach over 90%.

With 2024 Aluminum: Prevent galvanic corrosion by applying insulation coatings or transition layers at the joints. When using TIG welding, 2319 wire is recommended, followed by anodizing treatment to enhance corrosion resistance.

Case Studies

Shipbuilding: 5456 aluminum is widely used in the welded structures of high-speed vessels such as hydrofoils and hovercrafts. With 5356 wire and pulsed arc welding, weld strength can exceed 80% of the base metal.

Aerospace: In auxiliary aircraft structures, welding 5456 to high-strength alloys like 7075 requires caution due to heat-affected zone softening. Local heat treatment is usually applied post-weld to restore performance.

Conclusion

In the face of future challenges like higher strength requirements and harsher marine conditions, combining 5456 aluminum with advanced welding techniques such as laser welding or friction stir welding (FSW) will continue to drive innovation in green shipbuilding and high-end equipment manufacturing.

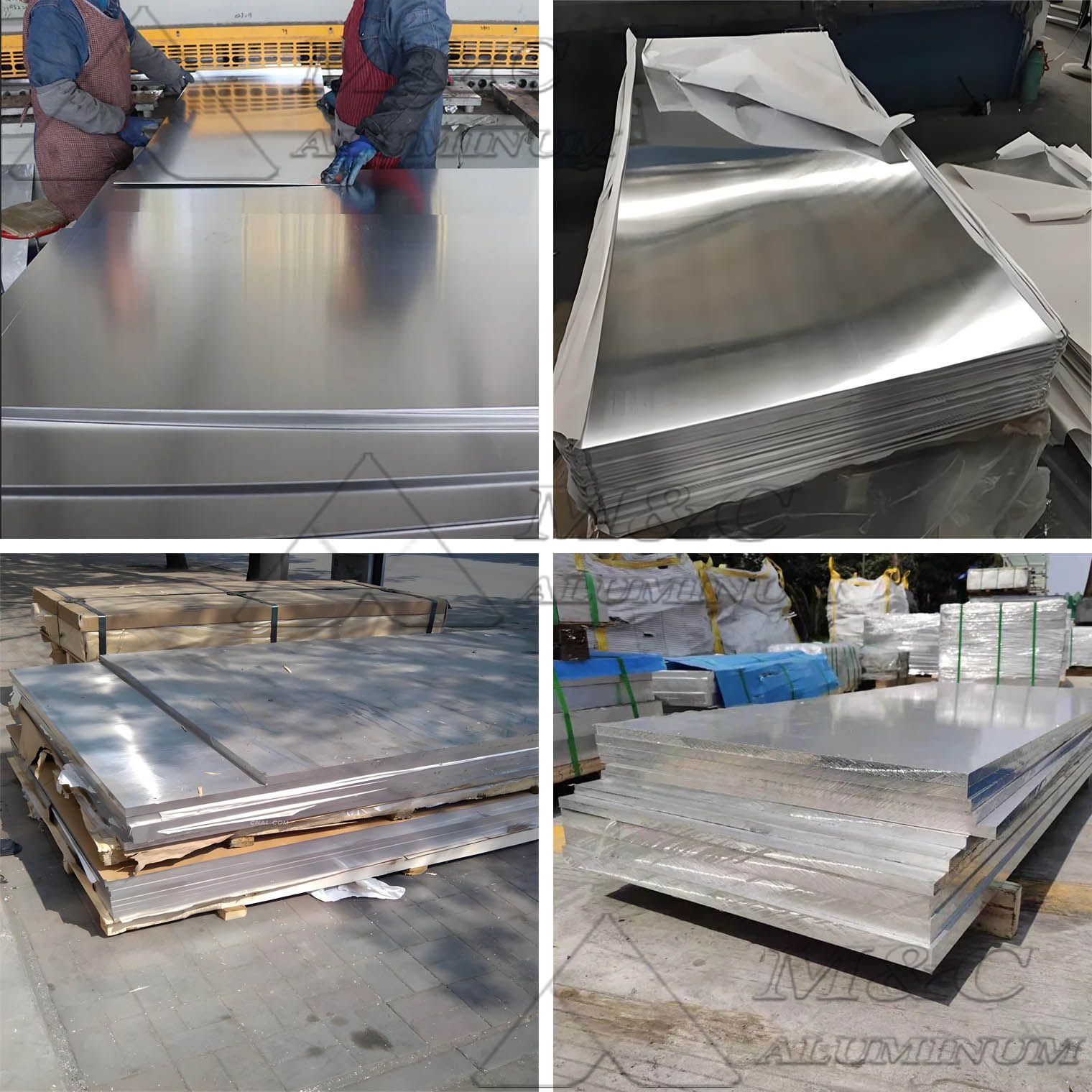

MC Aluminum is a professional manufacturer specializing in marine-grade aluminum products. We offer 5xxx and 6xxx series marine aluminum plates including 5083, 5456, 5059, 5052, 6061, 6082, and 6063. Our products come in various tempers, offer excellent flatness, and are customizable in size. We also produce marine welding materials such as 5356 and 5183 welding wires. Our products are exported worldwide and trusted by clients. Factory-direct pricing, free samples, and technical support are available. For more information, feel free to contact us.