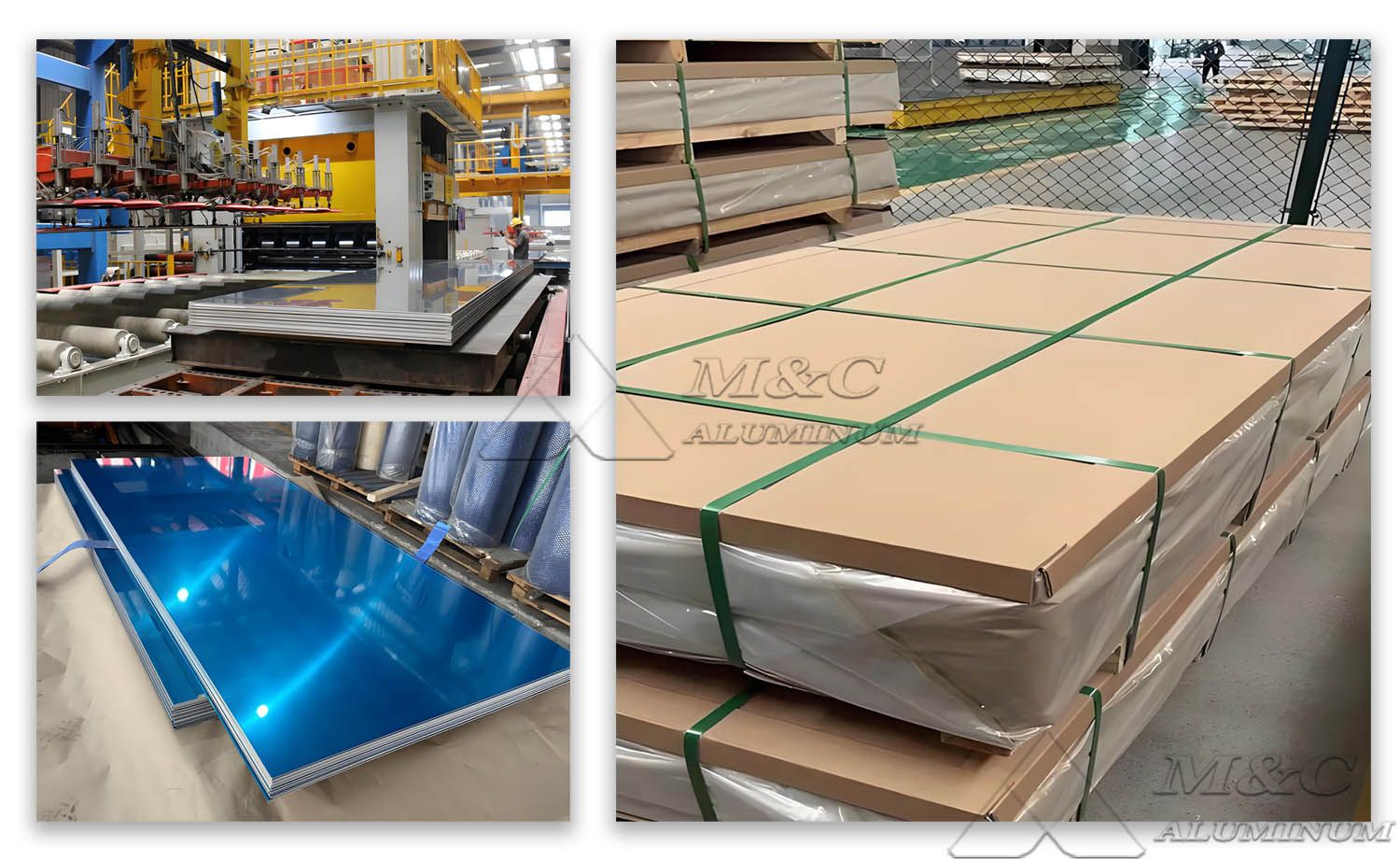

Why Choose MC Aluminum’s 5059 Marine Grade Plate?

MC Aluminum uses high-quality raw materials and advanced equipment, including "1+1" and "1+4" six-high cold rolling mills, to strictly control the production process. Our 5059 marine aluminum plates have passed certifications from CCS, DNV, NK, ABS, BV, LR, KR, and more.

Overview of 5059 Marine Grade Aluminum Plate

5059 aluminum alloy is a high-strength, corrosion-resistant alloy in the Al-Mg (aluminum-magnesium) series, developed by a German aluminum company. As one of the strongest-performing alloys in the 5xxx series, it contains 5.0–6.0% magnesium, providing excellent strength and outstanding resistance to seawater corrosion. Initially developed for military vessels and fast patrol boats, it is now widely used in civilian applications such as yachts, passenger ferries, and offshore wind platforms.

MC Aluminum produces 5059 marine aluminum plates in thicknesses from 3 mm to 50 mm, available in multiple tempers: O, H111, H112, H114, H116, and H321.

Heat Treatment Tempers Explained: O, H111, H116, H321

Marine-grade aluminum plates are often treated to achieve specific mechanical and corrosion-resistant properties.

O Temper (Annealed)

Properties: Fully annealed condition. Offers the best ductility and formability but lower strength.

Applications: Suitable for deep drawing, complex forming, or bending, such as hull contours, tank heads, and other parts requiring high flexibility without cracking.

H111 Temper

Properties: Lightly strain-hardened with no additional thermal treatment. Offers improved strength over O temper while retaining good formability.

Applications: Ideal for side shells, bulkheads, deck structures, and parts needing moderate strength and good workability.

H116 Temper

Properties: Specifically designed for Al-Mg alloys with >4% Mg. Provides excellent resistance to exfoliation corrosion, a type of intergranular corrosion common in marine environments. Achieved through controlled strain hardening and stabilization.

Applications: Used in critical above-waterline and exposed areas such as hull sides, deck houses, and superstructures.

H321 Temper

Properties: Strain-hardened to a degree between H32 and H34. Offers greater strength than H111 while maintaining toughness. Similar to H116 in corrosion resistance, with enhanced resistance to stress corrosion cracking.

Applications: Suited for keels, beams, pressure vessels, and primary load-bearing components in military and high-performance vessels.

Mechanical Properties of 5059 Marine Aluminum Plate

| Alloy | Temper | Thickness mm | Tensile Strength RmMPa | Specified non-proportional tensile strength Rp0.2 Mpa | Elongation% | |

| A50mm | A | |||||

| 5059 | O | 3-50 | 330-380 | ≥160 | ≥24 | ≥24 |

| H111 | 3-50 | 330-380 | ≥160 | ≥24 | ≥24 | |

| H116 | 3-20 | ≥370 | ≥270 | ≥10 | ≥10 | |

| >20-50 | ≥360 | ≥260 | - | ≥10 | ||

| H321 | 3-20 | ≥370 | ≥270 | ≥10 | ≥10 | |

| 20-50 | ≥360 | ≥260 | - | ≥10 | ||

| Corrosion Resistance | ||||||

Exfoliation Corrosion (H116 & H321): Intergranular Corrosion (H116 & H321): | ||||||

Chemical Composition of 5059 Aluminum (Typical Values %)

Grade | Max(%) | ||||||||

Alloy 5059 | Si | Fe | Cu | Mn | Mn | Cr | Zn | Ti | Al |

0.45 | 0.5 | 0.25 | 0.6-1.2 | 5.0-6.0 | 0.25 | 0.40-0.9 | 0.2 | Remainder | |

Core Advantages of Marine-Grade 5059 Aluminum Plate

1. High Strength & Lightweight

5059 offers higher yield and tensile strength than 5083, allowing for thinner plate use to reduce vessel weight.

2. Enhanced Vessel Performance

Lightweight design increases speed, improves fuel efficiency, and enhances cargo capacity and maneuverability—ideal for high-speed boats, naval ships, and performance yachts.

3. Outstanding Corrosion Resistance

Exceptional resistance to seawater, pitting, and crevice corrosion. Post-treatment enhances resistance to exfoliation and stress corrosion cracking.

4. Excellent Weldability

Compatible with MIG and TIG welding, ensuring strong, corrosion-resistant joints and simplified manufacturing.

5. Long Service Life & Low Maintenance

Strong mechanical and anti-corrosion properties reduce maintenance needs and extend lifespan.

Typical Applications of 5059 Marine Aluminum

High-Performance Vessels:

High-speed passenger ferries, yachts, patrol boats — applications where speed and fuel efficiency are critical.Military Ships:

Destroyers, frigates, amphibious landing ships requiring high strength, corrosion resistance, and impact toughness.Offshore Structures:

Components in offshore platforms, floating structures, and deep-sea equipment demanding durability and low weight.Cryogenic Containers:

Ideal for LNG storage tanks on liquefied natural gas carriers, maintaining excellent performance at low temperatures.

Surface Quality Requirements for 5059 Marine Plate

1. Chemical Composition

Magnesium Content: Typically 5.2%–5.8%, directly impacts strength and corrosion resistance.

Impurity Control: Strict limits on Fe, Si, Cu to ensure alloy purity and performance stability.

Trace Elements: Chromium, zirconium, titanium may be added to refine grain structure and enhance corrosion resistance.

2. Mechanical Properties

Tensile Strength: ≥370 MPa for structural integrity under load.

Yield Strength: ≥270 MPa for load-bearing before deformation.

Elongation: ≥10% to ensure flexibility during forming and service.

3. Corrosion Resistance

Seawater Resistance: Must perform reliably in harsh marine environments (salt, humidity).

Intergranular & Exfoliation Corrosion:

Intergranular corrosion loss ≤15 mg/cm², exfoliation rated Grade PA or better.

4. Surface Appearance

Flatness: Plates must be flat and smooth, free of waves or warping.

Defects: No cracks, inclusions, or bubbles allowed.

Oxide Film: Anodizable plates must have uniform, dense, and intact oxide layers for durability and aesthetics.

5. Processing Performance

Weldability: Excellent compatibility with welding processes.

Formability: Good for cutting, bending, shaping to suit complex shipbuilding needs.

Heat Treatability: Responds well to thermal treatments for performance enhancement.