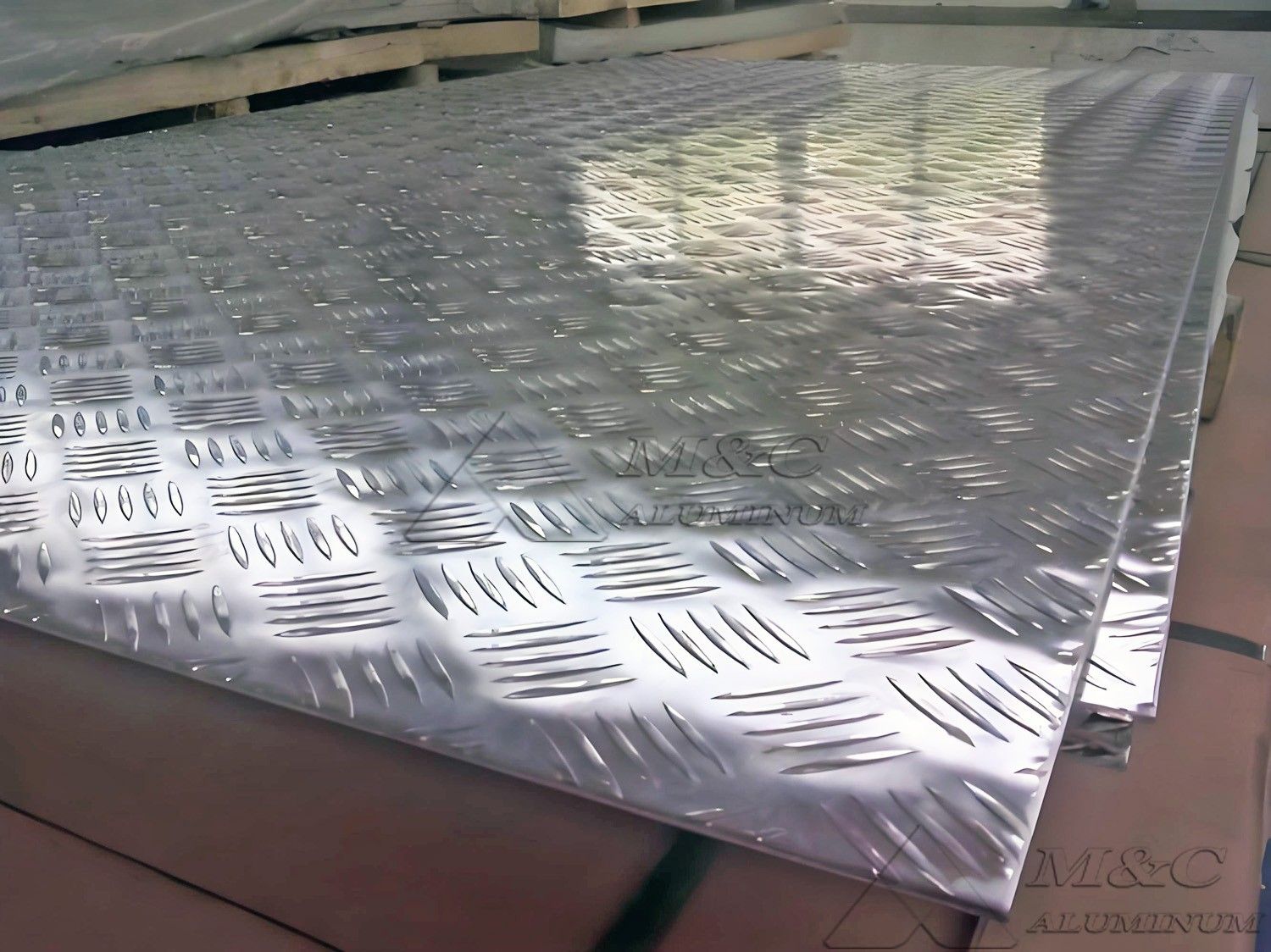

In modern shipbuilding and offshore engineering, safety and durability are the core criteria for material selection. Among them, 5083 patterned aluminum plates have become a common choice for decks, gangways, passageways, and engine room walkways due to their excellent anti-slip properties and resistance to seawater corrosion. However, to meet stringent marine standards, these plates must adhere to specific production and application requirements.

On most marine decks, the most commonly used is a 5mm thick bean-shaped patterned 5083 aluminum plate, which not only resists seawater corrosion but also prevents crew members from slipping. In a certain ocean-going fishing vessel deck renovation project, after replacing with marine 5083 patterned aluminum plates, the maintenance cycle was extended from 1 year to 5 years, and overall costs were reduced by 60%.

Performance Advantages of Marine 5083 Patterned Aluminum Plate

High Strength: With magnesium as the main alloy element, 5083 patterned aluminum plate has outstanding strength, able to withstand various stresses during navigation, ensuring structural safety in critical areas like decks.

Strong Corrosion Resistance: The marine environment is highly corrosive to metals. 5000 series marine aluminum plates such as 5052 and 5083 offer excellent corrosion resistance, capable of long-term use in humid and salty conditions without rust, thereby extending vessel lifespan.

Good Workability: Shipbuilding requires cutting, punching, bending, and other processing. 5083 patterned aluminum plates offer excellent plasticity, allowing for easy shaping and sizing to meet diverse manufacturing needs.

Easy Welding: The material has excellent weldability, compatible with various welding methods, ensuring structural integrity and airtightness in ships.

Low Density: Compared with other alloys, 5083 patterned aluminum has a lower density, reducing vessel weight, improving navigation efficiency, and lowering energy consumption.

Anti-Slip Function: The most important feature is the raised surface patterns (e.g., one bar, three bars, five bars, diamond shapes). These textures offer superior anti-slip performance, making them ideal for decks, floors, passageways, and ramps to ensure crew and passenger safety.

Product Certification: Marine-grade 5083 aluminum plates must often be certified by classification societies such as CCS (China), DNV (Norway), LR (UK), and ABS (USA) to ensure compliance with international shipbuilding quality and safety standards.

Product Information for Marine Patterned Aluminum Plate

| Alloy | 5083 |

| Temper | H116, H321 (optimal corrosion resistance) |

| Thickness | 1.0-8.0 mm (decks typically 3-6 mm) |

| Width | 1000-2600 mm |

| Length | ≤8000 mm |

| Pattern Types | bean-shaped, pointer-shaped, five-bar, etc. |

| MOQ | 1-3 tons |

Common Pattern Types

Bean-Shaped Pattern: Continuous oval bumps with anti-slip coefficient of 0.8-1.0 (dry state), suitable for pedestrian areas such as decks and chemical plant platforms.

Five-Bar Pattern: Five parallel raised bars, strong longitudinal load-bearing capacity, anti-slip coefficient 0.7-0.9, stable anti-slip performance, good drainage, ideal for decks and gangways.

One-Bar Pattern: Used for corridors or maintenance platforms, facilitating trolleys or equipment movement.

Diamond Pattern: Evenly distributed diamond-shaped protrusions with anti-slip coefficient 0.7-0.9, excellent compression resistance, and outstanding slip prevention in wet environments.

Pattern height is generally 0.8-1.2 mm, ensuring adequate friction without affecting cleaning and maintenance.

Quality Control for 5083 Marine-Grade Patterned Aluminum Plates

1. Pattern Integrity: No broken corners or dents; protrusion height meets standard; pattern consistency deviation ≤0.3 mm within the same batch.

2. Mechanical Properties: Tensile strength ≥270 MPa, elongation ≥12% (H111 temper), ensuring no cracking under load or impact.

3. Corrosion Resistance: After anodizing or passivation, neutral salt spray test for 480 hours shows no red rust.

4. Flatness: Plate warpage ≤5 mm/m to avoid gaps during installation.

Marine applications also require non-destructive testing (UT flaw detection) to ensure no internal pores or inclusions, with a 100% pass rate.

Advantages Compared to Other Anti-Slip Materials

Compared to anti-slip steel, 5083 patterned aluminum sheet is lightweight, highly corrosion-resistant, and requires no painting or maintenance, resulting in a 40%-50% reduction in lifecycle costs. Compared to 3003 patterned aluminum sheet, 5083 is 50%-80% stronger, making it more suitable for load-bearing applications. Compared to rubber anti-slip mats, it offers superior wear resistance, a service life 5-10 times that of rubber, and is heat-resistant (it can withstand temperatures up to 150°C, whereas rubber tends to age at temperatures above 80°C).

In terms of price, the unit price of 5083 patterned aluminum sheet is higher than 3003 and 1060 patterned aluminum sheet (approximately 30%-50% higher), but lower than 304 stainless steel patterned plate (approximately 40%-60% lower), offering outstanding value for money in mid- to high-end anti-slip and corrosion-resistant applications.

Original Source: https://www.marinealum.com/a/what-are-the-requirements-for-5083-patterned-aluminum-plates-for-ship-anti-skid-use.html

Tag: marine patterned aluminum plate 5083 marine aluminum plate 5083 patterned aluminum plate 5083 marine-grade patterned aluminum plate marine 5083 patterned aluminum plate marine-grade aluminum plate 5083 marine aluminum 5-series marine aluminum plat