In the field of shipbuilding, lightweight construction is a key goal to improve vessel speed and fuel efficiency. Aluminum alloys, with their low density and excellent corrosion resistance, are increasingly replacing traditional steel structures. Among them, 5083 aluminum plate stands out as one of the most commonly used marine-grade alloys. With its high strength, exceptional corrosion resistance, and suitability for harsh marine environments, 5083 aluminum is widely used for hull structures, decks, control platforms, and other critical components.

5083 marine aluminum plates are commonly supplied in H116, H321, and H112 tempers, and are used for yacht hulls, cruise ships, and fishing vessels. Beyond the benefits of weight reduction, ships constructed with aluminum plates achieve higher speeds under the same power conditions and enjoy a longer service life, making 5083 aluminum a preferred material for modern ship design.

How 5083 Aluminum Plate Meets Marine-Grade Requirements

1. High Strength and Lightweight Advantages

5083 aluminum sheet has a density of only approximately 2.7-2.8 g/cm³ and an elastic modulus of 70-73 GPa, significantly lower than steel. This reduces ship weight while maintaining comparable strength. 5083 aluminum sheet also boasts a tensile strength of 110-136 MPa, a yield strength of ≥110 MPa, and an elongation (δ10) of ≥20%. This combination of moderate strength and high elongation ensures the safety of ship structures under dynamic loads.

2. Excellent Corrosion Resistance

5083 aluminum plate exhibits outstanding corrosion resistance in seawater, freshwater, and industrial atmospheres. A dense oxide film forms naturally on the surface, effectively blocking chloride ion penetration and preventing pitting or stress corrosion cracking.

The H116 and H321 tempers undergo special treatments, making them even more suitable for long-term service in humid, high-salinity marine environments.

3. Superior Welding and Fabrication Properties

5083 aluminum is highly weldable and can be joined using TIG, MIG, and other common welding techniques. Post-weld strength retention is excellent. The alloy’s good ductility makes it ideal for forming processes such as stamping, bending, and deep drawing, which are essential for complex ship structures.

4. Outstanding Fatigue Resistance

Ships experience continuous cyclic loading from waves and navigation. Materials must therefore have excellent fatigue resistance. 5083 aluminum, with its stable grain structure and uniform internal organization, maintains its mechanical properties under repeated stress, thereby extending the vessel’s service life.

5. Cold and Hot Forming Capabilities

During shipbuilding, materials undergo both cold forming (e.g., flanging, rolling, stamping) and hot forming (e.g., hot bending, flame straightening). Marine aluminum alloys must resist cracking during processing while maintaining strength and corrosion resistance afterward. 5083 aluminum plate meets these strict processing and performance requirements, making it ideal for marine applications.

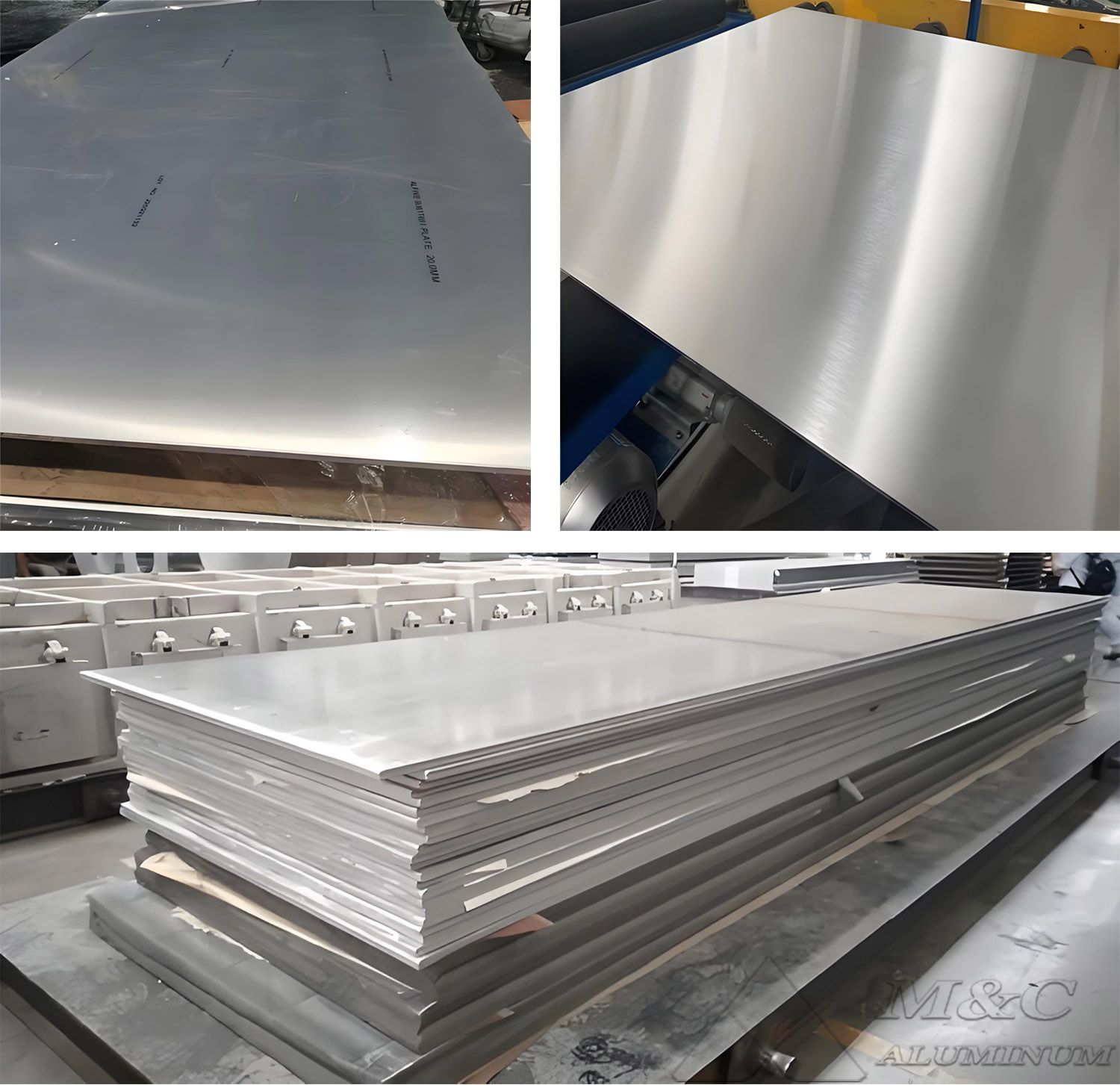

Applications of 5083 Aluminum Plate in Shipbuilding

5083 aluminum plate is widely used in ship construction, including hulls, decks, control consoles, and other structural components. Its most critical application is in the underwater sections of the hull, where corrosion resistance and structural strength are paramount.

It is also frequently used in ship sheet metal components and body panels for large vessels and yachts. As a professional anti-rust aluminum plate, 5083 is indispensable in both traditional and modern shipbuilding. It covers side and bottom plating in vessel structures-some of the most critical load-bearing areas.

Classification Society Certifications

5083 aluminum plate is certified by major international classification societies, including DNV/GL, CCS, LR, ABS, and others. Classification certification ensures that the chemical composition, mechanical properties, and production process of 5083 aluminum meet strict international shipbuilding standards, guaranteeing reliable quality and performance.

Specifications and Tempers of Marine 5083 Aluminum Plate

5083 marine aluminum plate is available in a wide range of thicknesses, from 0.15mm to 600mm, and widths from 300-2600mm, meeting the design requirements of various ship structures.

In terms of material properties, 5083 aluminum plate is available in various finishes, including O, H12, H14, H16, H18, H19, H22, H24, H26, H28, H32, H34, H36, H38, H111, H112, H114, H116, and H321.

As a professional marine aluminum manufacturer, MC Aluminum not only produces 5083 marine aluminum, but also provides 5086, 5059, 5456, 5754, 6061, 6063, 6082 and other marine aluminum alloys. Our products have stable quality, a complete range of specifications, are sold directly from the factory, and are at preferential prices. We also export to overseas markets. Users can consult and place orders at any time.

Original Source: https://www.marinealum.com/a/5083-aluminum-plate-meets-the-performance-requirements-for-marine-grade-aluminum.html

Tag: 5083 aluminum plate 5083 marine aluminum plate 5083 H116 marine aluminum plate 5083 H321 marine aluminum plate 5083 H112 marine aluminum plate marine aluminum alloy 5083 marine aluminum marine aluminum manufacturer