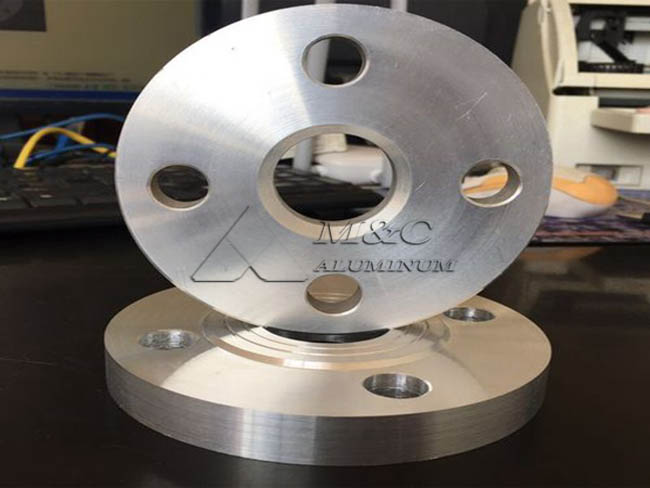

The 6061 aluminum flat slip-on flange is a type of flange manufactured from 6061 aluminum alloy. Its structural feature is that the inner diameter of the flange is slightly larger than the outer diameter of the pipe. During installation, the pipe can be directly inserted into the flange bore and then secured by fillet welding on both the inner and outer sides.

The "Flat Face (FF)" design ensures uniform contact pressure between the flange sealing surface and the gasket. It is particularly suitable for use with aluminum pipes or other lightweight piping materials and effectively reduces the risk of leakage caused by stress concentration.

MC Aluminum manufactures 6061 marine aluminum flanges specifically for marine environments. These products comply with the stringent requirements of the International Maritime Organization (IMO) and major classification societies such as ABS, DNV, and CCS, and are designed to withstand the vibration, temperature fluctuations, and corrosive conditions typical of marine applications.

Aluminum Flange Specifications

| Alloy | 6061 |

| Temper | T4, T6 |

| Standards | Standards: ANSI B16.5, ANSI B16.47 Series A & B, MSS SP-44, ASA, API-605, AWWA, custom drawings |

| Size Range | 1/2" (15 NB) to 48" (1200 NB) |

| Pressure Ratings | Class 150, 300, 600, 900, 1500, 2500; DIN PN 6, 10, 16, 25, 40, etc. |

| Facing Types | Flat Face (FF), Raised Face (RF), Ring Type Joint (RTJ) |

| BS Standards | BS4504, BS1560, BS10 |

| DIN Standards | DIN2527, DIN2566, DIN2573, DIN2576, DIN2641, DIN2642, DIN2655, DIN2656, DIN2627, DIN2628, DIN2629, DIN2631, DIN2632, DIN2633, DIN2634, DIN2635, DIN2636, DIN2637, DIN2638, DIN2673 |

| Surface Treatment | Mill finish / anodized / anti-corrosion coating |

| Manufacturing Process | Forged or machined |

Material Advantages of 6061 Aluminum Alloy in Marine Applications

6061 aluminum alloy belongs to the Al-Mg-Si series of heat-treatable alloys and has a proven track record in marine structures and piping systems. Its key advantages include:

1.Excellent Corrosion Resistance

6061 aluminum alloy offers good resistance to seawater and humid environments. With anodizing or protective coatings, its service life can be further extended.

2.Optimal Balance of Strength and Light Weight

Compared with steel flanges, 6061 aluminum flanges significantly reduce weight, helping to lower vessel load and improve fuel efficiency.

3.Good Weldability and Machinability

6061 aluminum alloy provides stable welding performance, making it suitable for on-site installation and maintenance in shipyards, with overall excellent machinability.

4.Stable Mechanical Properties

Common tempers such as T6 and T651 offer high strength and dimensional stability, meeting the structural requirements of marine piping systems.

5.Environmentally Friendly and Recyclable

Recycling aluminum requires only about 5% of the energy needed to produce primary aluminum.

Structural Features of Flat Slip-On Flanges

Compared with welding neck flanges and other types, flat slip-on flanges offer distinct advantages in marine systems:

Easy Installation: No complex beveling required; the pipe simply slips into the flange for welding

Cost-Effective: Relatively simple manufacturing process with controlled overall cost

Reliable Sealing: Flat face design is suitable for low- to medium-pressure piping systems

Uniform Stress Distribution: Flat contact surface reduces the risk of localized stress concentration

Typical Marine Applications

Ship cooling water piping systems

Ballast water piping and auxiliary pipelines

Marine ventilation and drainage systems

Lightweight piping systems for offshore platforms

Piping connections for aluminum vessels and high-speed craft

Installation and Maintenance Recommendations

Prevention of Galvanic Corrosion

When aluminum flanges are connected to steel piping, insulating gaskets and sleeves must be used to interrupt the electrical circuit and prevent galvanic (sacrificial anode) corrosion.

Cleaning and Surface Protection

Clean flange surfaces with neutral detergents. Avoid acidic or alkaline cleaning agents.

Welding Control

TIG (GTAW) or MIG (GMAW) welding is recommended. Heat input should be strictly controlled to prevent degradation of mechanical properties in the heat-affected zone.

Original Source: https://www.marinealum.com/a/marine-6061-aluminum-flat-slip-on-flange.html

Tag: Aluminum flange marine aluminum flange aluminum flat slip-on flange pipe fittings 6061 marine aluminum aluminum alloy flange 6061-T6 aluminum flange flat face flange marine piping accessories welding neck flange