5086 marine aluminum plate belongs to the 5xxx anti-rust aluminum series, commonly available in tempers such as O, H111, H112, H116, and H321. It is widely used in applications requiring high corrosion resistance, good weldability, and medium strength, such as hull structures, decks, superstructures, ship side panels, and bottom plates. It has significant potential in the marine aluminum market.

Among these, H116 is a special temper of 5086 aluminum alloy. Through specific work-hardening and heat treatment processes, it maintains excellent strength while offering enhanced resistance to exfoliation corrosion-a critical property for vessels exposed to harsh marine environments over long periods.

MC Aluminum produces 5086 H116 marine aluminum plates certified by ABS, DNV, CCS, and other classification societies, meeting international shipbuilding standards.

Core Features and Advantages of 5086 Marine Aluminum Plate

Corrosion Resistance: Specifically designed for seawater environments, 5086 marine aluminum outperforms ordinary aluminum alloys (such as 5052 and 6061) in salt spray corrosion resistance, maintaining structural integrity even after long-term exposure to marine conditions.

Fatigue Resistance: Suitable for high-vibration environments (e.g., wave impact on hulls), prolonging service life.

Weldability: Excellent weldability, compatible with MIG/TIG and other conventional processes, with minimal post-weld strength loss, ideal for continuous hull welding.

Lightweight: Density is only about one-third that of steel, reducing vessel weight while improving speed and fuel efficiency.

Low-Temperature Toughness: Retains toughness even at sub-zero temperatures, suitable for polar navigation vessels.

Product Information of 5086 Marine Aluminum Plate

| Alloy | 5086 |

| Temper | H116 |

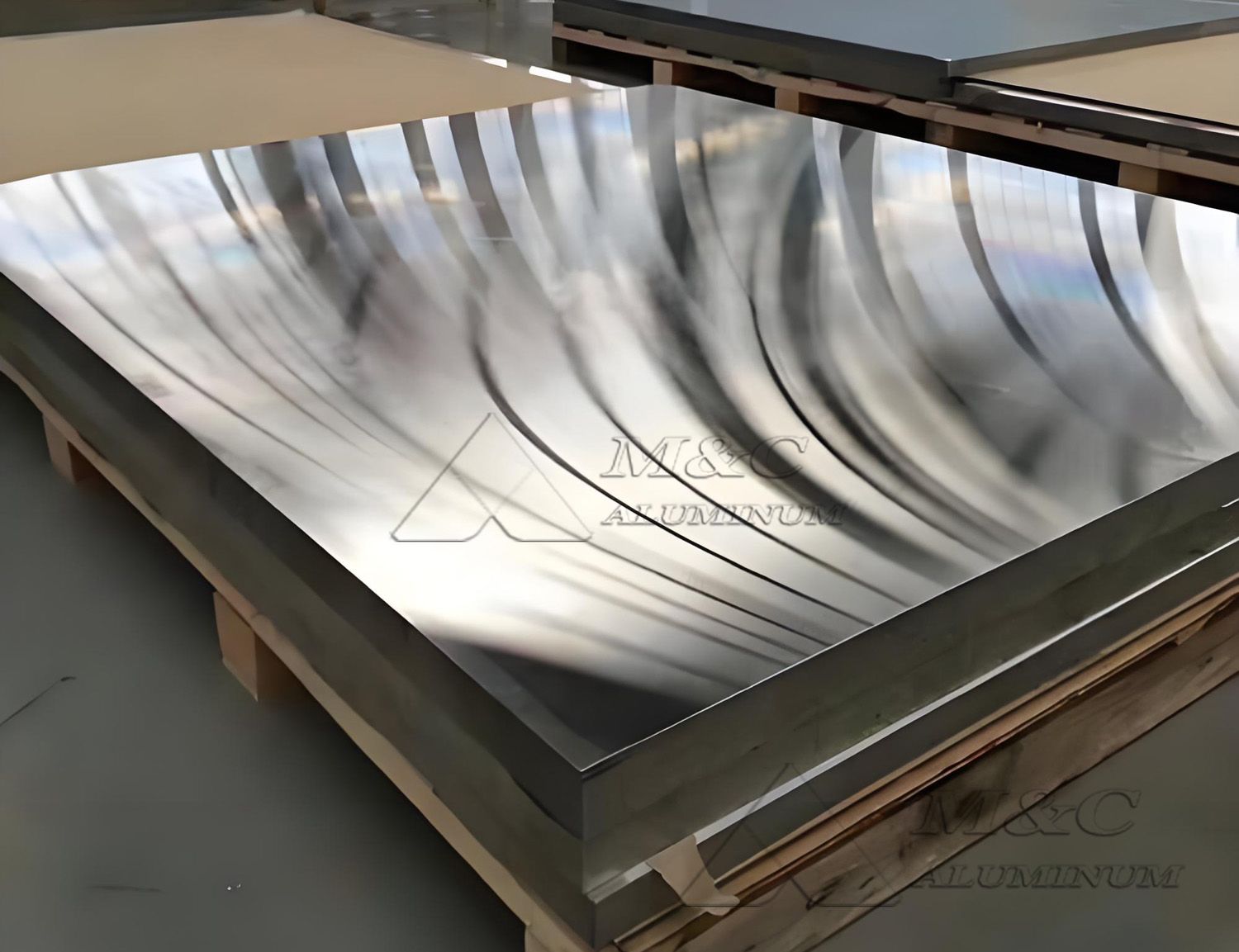

| Thickness | 3–50 mm |

| Width | 100–2650 mm |

| Length | 2000–16000 mm |

| Mother Coil | CC or DC |

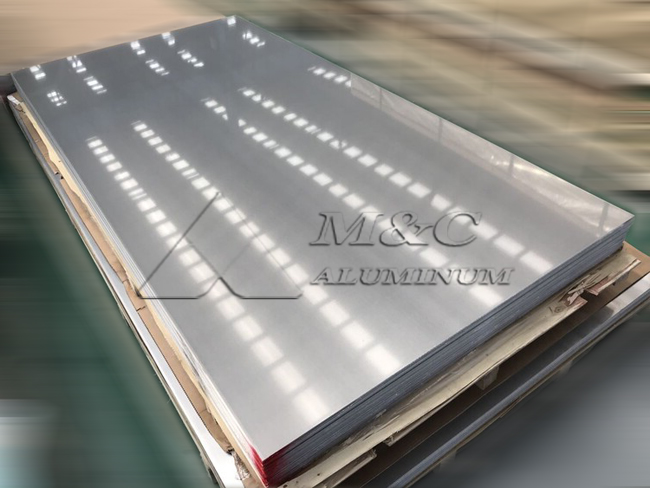

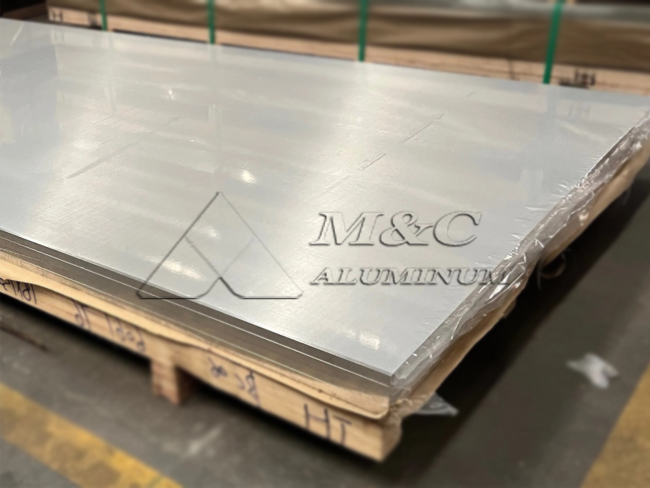

| Weight | Approximately 2 tons per pallet for standard sizes |

| MOQ | 1-3 tons |

| Protection | Paper interlayer, white film, blue film, black-and-white film, micro-binding film, according to customer requirements |

| Surface | Smooth and bright, free from stains, corrosion, oil, or splits |

| Delivery Time | About 30 days after deposit |

| Payment | T/T (Telegraphic Transfer), L/C |

| Trade Terms | FOB, CIF, or CFR |

Mechanical Properties

Tensile Strength: ≥ 275 MPa

Yield Strength: ≥ 240 MPa

Elongation: ≥ 12%

Density: 2.65 g/cm³

Applications of 5086 H116 Aluminum Plate in Shipbuilding

Applications of 5086 H116 Aluminum Plate in Shipbuilding

Modern shipbuilding increasingly emphasizes “lightweight + high corrosion resistance” designs, and 5086 H116 aluminum perfectly meets this trend. Common applications include:

High-Speed Passenger Ship Hulls: Lightweight materials reduce displacement, increase speed, and lower fuel consumption.

Offshore Workboat Decks: Anti-slip and corrosion-resistant deck materials ensure crew safety in harsh weather.

Yacht and Fishing Vessel Hulls: Durable, visually appealing, and easy to maintain, ideal for long-term marine use.

Marine Platform Components: Corrosion-resistant structural material for offshore wind farms, oil drilling rigs, and other marine engineering projects.

Comparison with Other Marine Aluminum Alloys

In shipbuilding, common marine aluminum alloys include 5086, 5083, and 6061. While all are suitable for marine environments, each has its focus.

5086 vs. 5083:

5083 has higher magnesium content, giving it greater strength, especially in thick plate applications. This makes 5083 ideal for large ships and high-strength structures.

5086 has slightly lower magnesium content, offering better weldability and formability, and is generally more cost-effective. It is often used for smaller vessels and non-critical structural components.

Summary: 5083 is preferred for high-strength thick plate applications, while 5086 balances strength, cost, and machinability.

5086 vs. 5052:

5052 has lower magnesium content than 5086, resulting in lower strength and hardness.

However, 5052 exhibits better formability and machinability, easier to bend and stamp.

Usage: 5086 is primarily used for high-strength hull structures, decks, and main keels, while 5052 is suitable for non-structural components like cabin partitions, storage lockers, or decorative parts.

5086 vs. 6061:

6061 is heat-treatable, achieving higher tensile strength than 5086.

However, 5086 significantly outperforms 6061 in seawater corrosion resistance and weldability. Weld zones in 6061 lose strength and corrosion resistance, a disadvantage in large welded structures like hulls.

Usage: 6061 is more commonly used for non-critical structures such as masts, railings, or equipment bases, whereas 5086 remains the preferred choice for hull structures.

Original Source: https://www.marinealum.com/a/5086-h116-aluminum-plate-sheet-for-shipbuilding.html

Tag: 5086 marine aluminum 5086 marine-grade aluminum plate 5086 ship aluminum plate marine-grade aluminum plate 5086 H116 marine aluminum plate 5086 H116 aluminum plate ship aluminum plate manufacturer