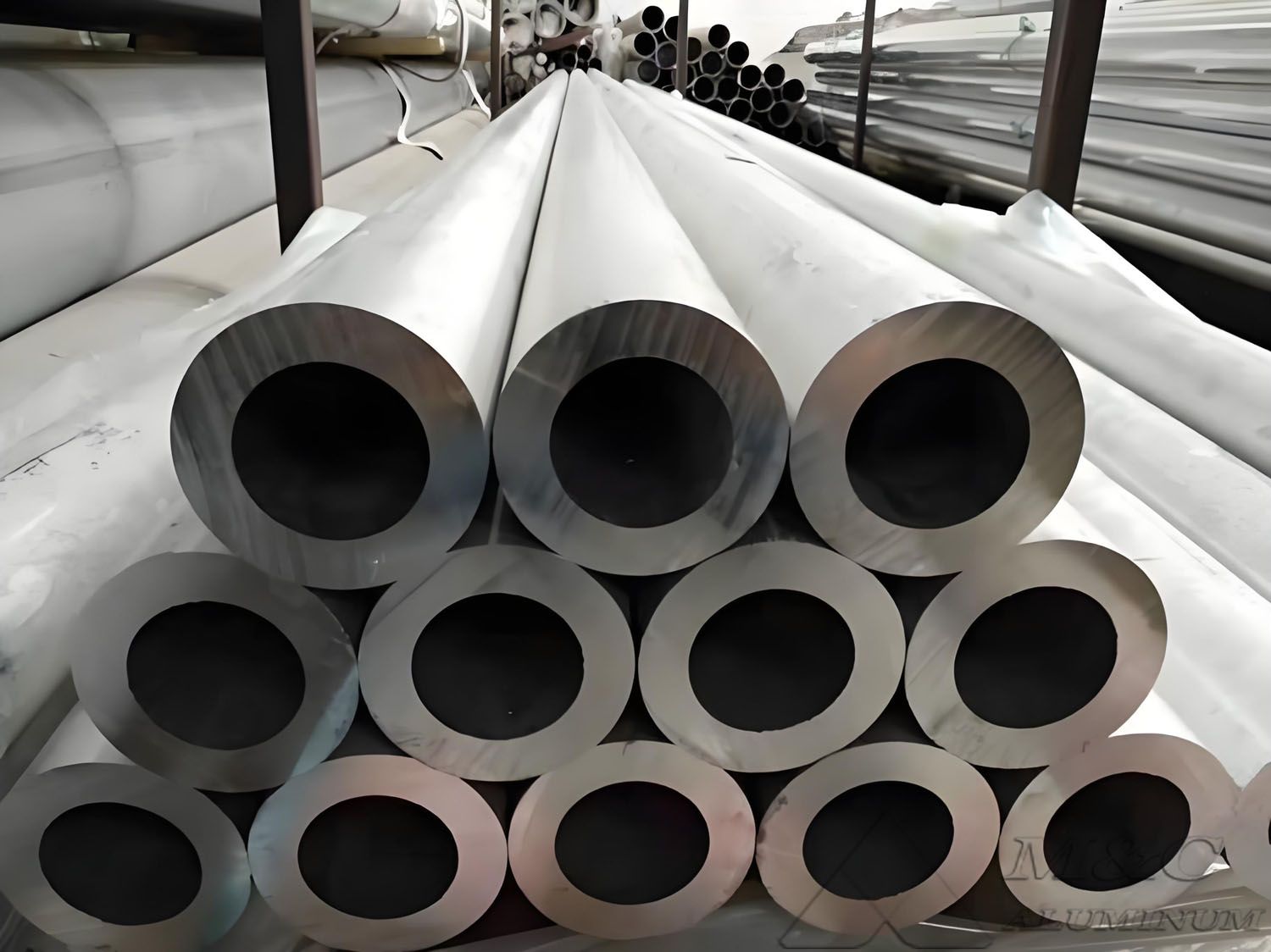

Marine grade aluminum tubes are indispensable structural components in modern marine engineering, combining lightweight characteristics with high mechanical strength. Among them, 6082 T6 aluminum alloy stands out due to its excellent strength, corrosion resistance, and weldability, making it a preferred material for ships, yachts, and offshore platforms.

The inclusion of an LR Certificate (Lloyd's Register approval) further ensures that these aluminum tubes comply with international maritime standards in design, manufacturing, and quality control, providing shipowners and contractors with confidence, regulatory compliance, and legal assurance.

6082 Aluminum Alloy Overview

6082 aluminum alloy belongs to the Al-Mg-Si (aluminum-magnesium-silicon) heat-treatable series and is one of the most widely used structural aluminum alloys in Europe. It achieves an excellent balance between high strength, weldability, and corrosion resistance.

Magnesium (Mg) and Silicon (Si) form strengthening phases that contribute to high mechanical strength

A controlled addition of Manganese (Mn) enhances toughness and significantly improves corrosion resistance, particularly against chloride ions in seawater

After solution heat treatment and artificial aging (T6 temper), the internal microstructure of 6082 aluminum is optimized, resulting in high strength and hardness suitable for demanding marine applications.

Common Supply Specifications for 6082 T6 Aluminum Tubes

| Alloy | 6082 |

| Outer Diameter | Wide customization range |

| Wall Thickness | Structural grade and pressure-grade available |

| Temper | T6 |

| Standards | EN 755 / EN 573 / ASTM (optional) |

| Certification | EN 10204 3.1 + LR (Lloyd’s Register) certificate |

| MOQ | 1-3 tons |

| Length Options | Fixed length, random length, or drawing-based customization |

Why Choose 6082 T6 Aluminum Tubes for Marine Applications?

1. Lightweight Advantage

Aluminum alloys have a density of approximately 2.7-2.8 g/cm³, only about one-third that of steel. Using aluminum tubes in superstructures, masts, walkways, or high-speed hull structures significantly reduces overall weight and lowers the vessel’s center of gravity.

2. Excellent Corrosion Resistance

6082 aluminum alloy exhibits outstanding corrosion resistance, further enhanced by its manganese content. This allows pipes, frames, and structural components made from 6082 to withstand marine salt spray and harsh offshore environments, reducing maintenance frequency and extending the vessel's service life.

3. High Strength with Good Machinability

6082 T6 is one of the strongest alloys in the 6000 series. Its tensile strength can reach 310 MPa and its yield strength can reach over 260 MPa, which is sufficient to meet the strength requirements of most marine structural components.

4. Good Weldability

6082 T6 aluminum tubes are well suited for TIG and MIG welding, producing reliable welds with low crack sensitivity when proper procedures are followed.

LR (Lloyd's Register) Certification

Lloyd's Register (LR) is one of the world's oldest and most authoritative classification societies. LR certification is widely regarded as the "gold standard" for marine materials.

For 6082 T6 aluminum tubes, LR approval confirms that:

Chemical composition complies with classification society requirements

Mechanical properties are verified by third-party testing

Manufacturing processes and quality systems are fully traceable

Materials are approved for direct use in shipbuilding and offshore inspection and acceptance

For export vessels, offshore engineering projects, and international tenders, LR certification is often a mandatory requirement.

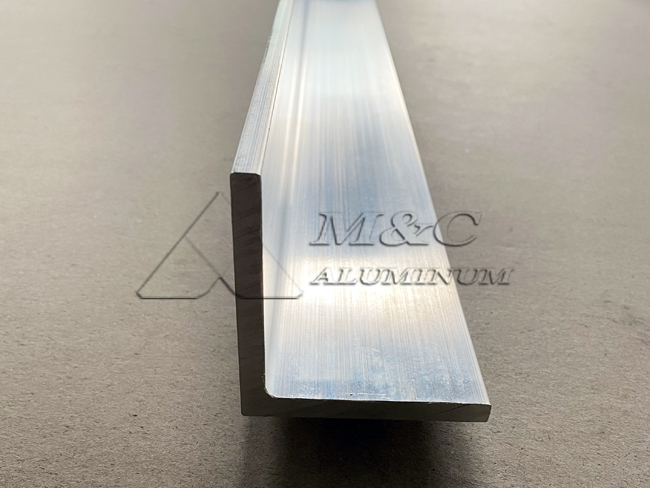

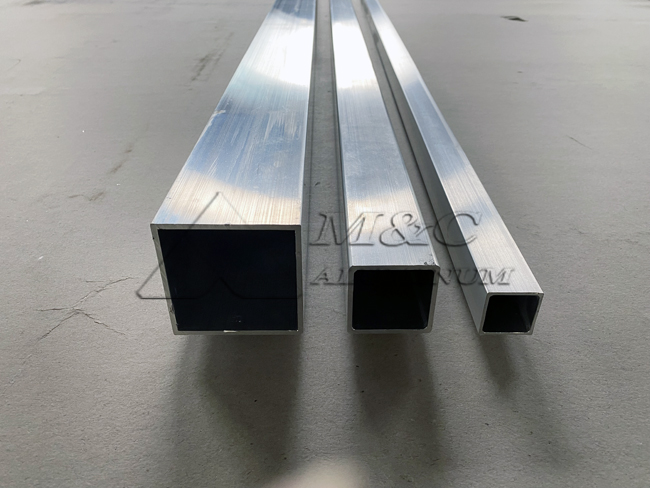

Typical Applications of Marine Grade 6082 Aluminum Tubes

1.Structural Framework

Used in ship ribs, auxiliary keel supports, and under-deck trusses, providing a high-strength, lightweight structural skeleton.

2.Piping Systems

Applied in seawater, freshwater, and air pipeline systems, where corrosion resistance ensures long-term operational reliability.

3.Safety Facilities

Commonly used for guardrails, handrails, ladders, and access structures, balancing safety, durability, and weight reduction.

6082-T6 Machining Guidelines

When using and machining this material, please note the following:

Welding: TIG or MIG welding can be used. 4043 or 5356 aluminum welding wire is recommended. Be aware that the strength of the heat-affected zone (HAZ) will decrease; critical structures may require compensation through post-weld heat treatment (such as re-aging) or optimized design.

Bending and Machining: In the T6 state, it has good formability but some springback. Complex bends may require specialized equipment. Machining performance is good, but it is recommended to use sharp carbide tools and ensure adequate cooling.

Material Comparison: Beyond 6082

In marine aluminum alloy selection, 6082 is often evaluated alongside 6061 and 6063. A comparison highlights the positioning of 6082 T6:

| Property | 6082 T6 | 6061 T6 | 6063 T6 | Marine Application Insight |

| Key Feature | Highest strength in 6000 series | Balanced, globally versatile | Excellent extrudability & surface finish | 6082 for load-bearing structures; 6063 for decorative and ventilation components |

| Tensile Strength | ~310–340 MPa | ~310 MPa | ~241 MPa | 6082 excels in hull frames and ribs |

| Corrosion Resistance | Excellent, Mn-enhanced for seawater | Very good | Excellent | All suitable for marine use; 6082 performs better in harsh environments |

| Weldability | Good (HAZ softening to consider) | Excellent | Very good | 6061 offers higher process tolerance; 6082 requires stricter welding control |

| Typical Marine Use | Hull structures, deck supports, large pipes | Superstructures, small vessels, outfitting | Window frames, interiors, railings, ventilation | Selection depends on load, formability, and cost |

Marine Grade 6082 T6 Aluminum Tubes, with their high strength, lightweight nature, excellent corrosion resistance, and good weldability, are an ideal choice for modern marine engineering.

The addition of an LR Certificate further guarantees product quality, regulatory compliance, and insurance acceptance, making these tubes widely used in shipbuilding, yacht construction, retrofitting projects, and offshore platforms.

Original Source: https://www.marinealum.com/a/marine-grade-6082-t6-aluminum-tube-with-lr-certificate.html

Tag: Aluminum tube 6082 T6 aluminum tube marine grade aluminum tube marine aluminum profile LR certified marine aluminum tube aluminum extrusion 6082 marine aluminum alloy LR approved aluminum tube marine aluminum alloy pipe