In the fields of shipbuilding and marine engineering, aluminum alloys-thanks to their lightweight nature, high specific strength, and excellent fabricability-have increasingly replaced traditional steel as key structural materials. However, seawater is a highly aggressive corrosive medium. Its high salt content, dissolved oxygen, and various impurities promote electrochemical corrosion, pitting corrosion, and crevice corrosion, all of which directly affect vessel service life and navigational safety.

As a representative alloy of the 6000 series marine aluminum alloys, 6061 aluminum alloy is widely used due to its well-balanced mechanical properties and machinability. Nevertheless, whether its corrosion resistance in seawater can withstand harsh marine environments, and how it compares with mainstream marine alloys such as 5083, 5052, and 5086 remains a core concern in material selection. The following sections provide a detailed analysis.

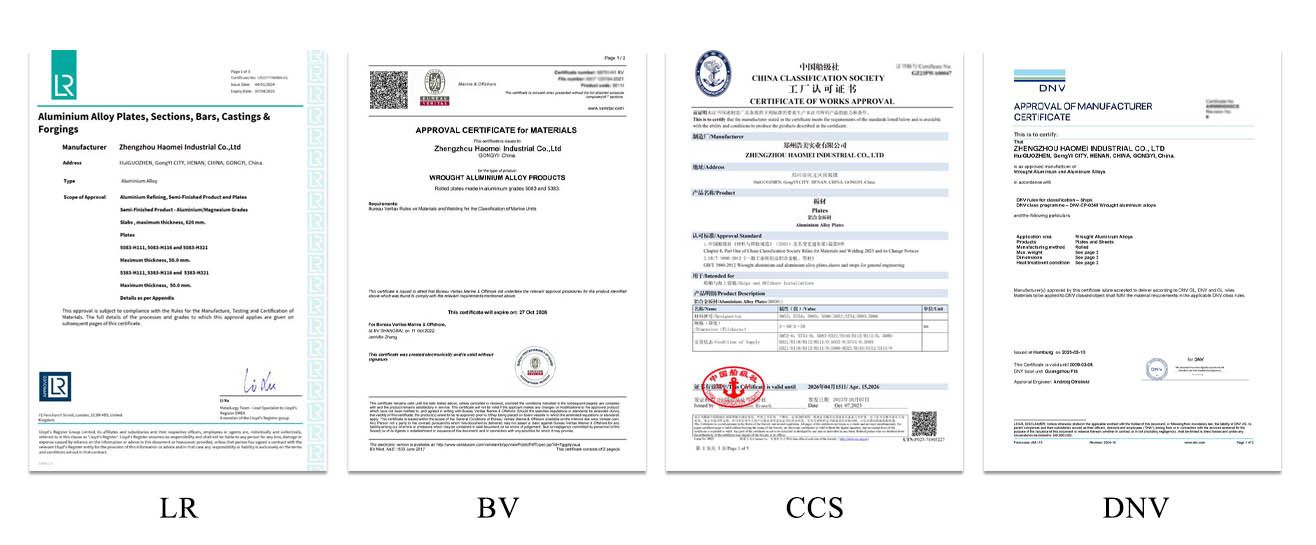

HAOMEI Aluminum is a professional manufacturer of marine aluminum materials, serving numerous well-known shipyards worldwide. Our products are certified by major classification societies, including DNV, NK, CCS, ABS, BV, LR, and KR, and are manufactured in compliance with international shipbuilding standards.

Overview of Marine Aluminum Alloys

5xxx Series Marine Aluminum Alloys

Represented by 5083, 5086, and 5456, these alloys are the primary materials for ship hull structures. The addition of magnesium enables the formation of a stable, dense, and highly "self-healing" oxide film in marine environments, giving them outstanding resistance to seawater corrosion-particularly against pitting corrosion and stress corrosion.

6xxx Series Marine Aluminum Alloys

6061 is the most typical alloy in this series. Magnesium and silicon form strengthening phases, allowing the alloy to achieve relatively high strength after heat treatment (such as T6 temper). It offers good overall performance, including moderate corrosion resistance, and is widely used in ship superstructures, masts, piping systems, outfitting components, and various brackets.

Corrosion Performance Showdown in Seawater Environments

1. General Corrosion and Pitting Corrosion

Advantages of the 5xxx Series:

The 5xxx series especially 5083 is often regarded as "true marine-grade aluminum." Due to its extremely low copper content, it rapidly forms a dense and stable aluminum oxide protective film in seawater. In long-term immersion tests, even when minor pitting occurs, corrosion propagation tends to stop quickly.

Weakness of 6061:

6061 contains a small amount of copper (approximately 0.15%-0.40%). While copper improves strength, in a strong electrolyte like seawater it can trigger micro-galvanic effects. As a result, pitting corrosion in 6061 is typically deeper than in 5083.

2. Intergranular Corrosion

The contrast is particularly evident in welded areas:

6061: As a heat-treatable alloy, its microstructure changes in the heat-affected zone (HAZ) during welding. If welding parameters are not properly controlled, intergranular corrosion may occur, leading to strength degradation.

5xxx Series: Even after welding, these alloys maintain stable corrosion resistance, which is a key reason they are preferred for medium and large ship hull structures.

3. Stress Corrosion Cracking (SCC)

When magnesium content exceeds 3% (as in 5083), the 5xxx series may become sensitized under high-temperature conditions (above 65 °C) combined with high stress. In comparison, 6061 generally exhibits better resistance to stress corrosion cracking, which explains its frequent use in structural components and fittings.

Summary: Corrosion Resistance Comparison

| Comparison Item | 6061 Aluminum Alloy | 5xxx Series Marine Aluminum |

| Alloy System | Al-Mg-Si | Al-Mg |

| Heat-Treatable | Yes | No |

| Pitting Sensitivity in Seawater | Relatively high | Low |

| Corrosion Resistance in Welded Zones | Moderate | Excellent |

| Long-Term Immersion Suitability | Limited | Outstanding |

| Suitability for Hull Structures | Not recommended | Recommended |

| Typical Applications | Internal structures, equipment parts | Hulls, decks, outer plating |

How Can 6061 "Turn the Tables" in Marine Applications?

Although its intrinsic corrosion resistance is inferior to that of 5083, 6061 still holds a position in marine engineering due to its excellent strength-to-weight ratio. To compensate for its limitations, the following protection measures are commonly adopted:

Anodizing:

An essential process for 6061. Hard anodizing forms a dense, ceramic-like oxide layer that significantly blocks seawater contact with the substrate.Sacrificial Anode Protection:

Installing zinc or magnesium anodes near 6061 structures ensures preferential corrosion of the anode, thereby protecting the aluminum component.High-Performance Coatings:

Multi-layer epoxy marine coatings are widely used to enhance corrosion protection.

Material Selection Recommendations

Common marine aluminum alloys include 6061, 5083, 5052, 5456, and 5086. How should the appropriate alloy be selected?

5xxx series (Al–Mg system):

Featuring a single-phase solid solution structure with optimized magnesium and manganese content, these alloys form stable oxide films and offer superior resistance to seawater corrosion.

6061 (Al–Mg–Si system):

Due to pronounced micro-galvanic effects, its oxide film is less stable, making it suitable only for low-corrosion-risk marine applications.

Industry Recommendations:

1. Submerged structures, hull shells, and tidal splash-zone components:

Prioritize 5083 aluminum alloy for its excellent corrosion resistance and mechanical properties. For complex curved components, 5086 offers a good balance between formability and corrosion resistance.

2. Non-load-bearing parts with limited seawater exposure (interior components):

5052 aluminum alloy provides the best cost-performance ratio, excellent formability, and requires minimal protection.

3. Non-immersed superstructures and mechanical brackets:

6061 aluminum alloy can be selected for its high specific strength and economic processing, combined with basic surface protection to meet service requirements.

4. Harsh marine environments (deep-sea platforms, ocean-going vessels):

6061 aluminum alloy should be strictly avoided. Priority should be given to 5083 or 5456 aluminum alloys (Mg content 4.7%-5.5%), which offer superior corrosion resistance and strength, reducing the risk of structural failure and ensuring navigational safety.

Conclusion

From the perspective of seawater corrosion resistance, 6061 aluminum alloy is not designed to excel in marine corrosion environments, but rather to deliver versatility and ease of fabrication. In contrast, 5xxx series marine-grade aluminum alloys are specifically engineered for marine service conditions.

In shipbuilding and marine engineering, a clear understanding of the corrosion behavior of different aluminum alloys in seawater is essential for ensuring structural safety, service life optimization, and effective life-cycle cost control.

Original Source: https://www.marinealum.com/a/in-depth-comparison-of-corrosion-resistance-6061-vs-mainstream-marine-aluminum-alloys.html

Tag: 6061 marine aluminum 5083 marine aluminum 5052 marine aluminum 5086 marine aluminum 6xxx marine aluminum alloys 5xxx marine aluminum alloys marine-grade aluminum aluminum plates for shipbuilding marine engineering aluminum alloys aluminum alloy m