Marine-grade aluminum alloy flange fittings refer to flanges and related connectors made from specialized marine aluminum materials such as 5083, 5052, and 6061. These components are commonly used in ship piping systems, liquid transport systems, power systems, and structural connections, serving purposes such as connection, sealing, reinforcement, and load transfer.

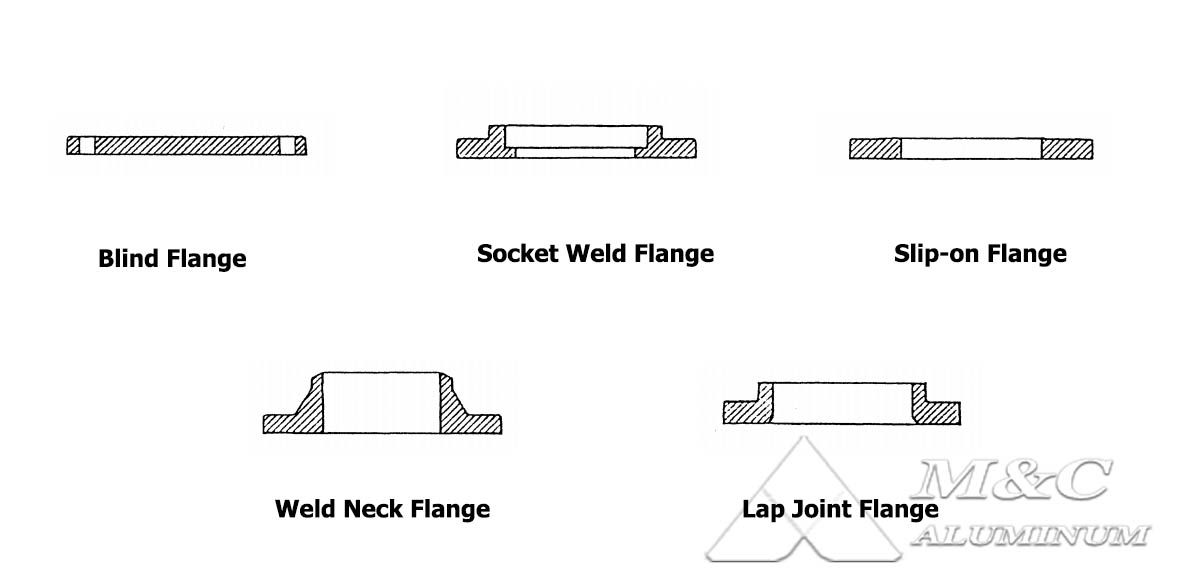

MC Aluminum manufactures and supplies high-quality aluminum alloy flanges, including flat flanges, raised-face flanges, recessed flanges, and back-to-back flanges. Our products are ISO9001 quality management system certified and hold classification society factory certifications, ensuring superior product quality.

Common Materials and Applications of Marine Aluminum Flanges

Marine aluminum alloy flanges mainly use alloys like 6061, 6063, and 5083, which have a density of only about one-third that of steel while offering excellent seawater corrosion resistance, making them ideal for high-salt marine environments.

5083 Aluminum Alloy

Most commonly used in scenarios requiring high strength and extreme corrosion resistance, such as main propulsion systems and fuel and cooling water piping systems.5052 Aluminum Alloy

Suitable for auxiliary system pipelines and connection points requiring high formability and moderate load-bearing capabilities.6061 Aluminum Alloy

A high-quality material balancing strength and machinability, often used for hydraulic piping connections and structural support components within ship cabins.

Advantages of Marine-Grade Forged Aluminum Flanges

1.Excellent Corrosion Resistance

Designed to withstand long-term operation in high-salt, high-humidity marine environments, particularly alloys like 5083 aluminum, which significantly extend the service life of the components.

2.Lightweight and High Strength

Aluminum alloys have about one-third the density of steel, significantly reducing overall vessel weight while maintaining strength, thus improving fuel efficiency and vessel speed.

3.Good Machinability

Aluminum alloys are easy to cut, weld, and form, providing flexibility in the manufacturing of flange fittings to meet complex connection requirements.

4.Eco-Friendly and Recyclable

Aluminum materials are 100% recyclable, supporting the green shipbuilding trend and reducing resource waste.

Applications of Aluminum Alloy Flanges

(1) Ship Piping Systems

Seawater Cooling Systems: Used to connect seawater pumps, condensers, and other equipment, designed to withstand seawater corrosion and high pressure.

Ventilation Systems: Including ventilation flanges under standards like CB/T 4337-2013 to ensure cabin air circulation.

Fuel and Lubrication Systems: Lightweight designs help reduce fuel consumption and improve operational economy.

(2) Offshore Engineering

Applicable for offshore platforms, FPSOs, and other demanding marine environments.

MC Aluminum manufactures a wide range of aluminum fittings, including flanges, elbows, tees, end reducer, and pipe caps, for piping systems. Our products are available in various types and can be customized according to your needs. With direct factory sales, overseas exports, and strong customer trust, you can place your orders with confidence.