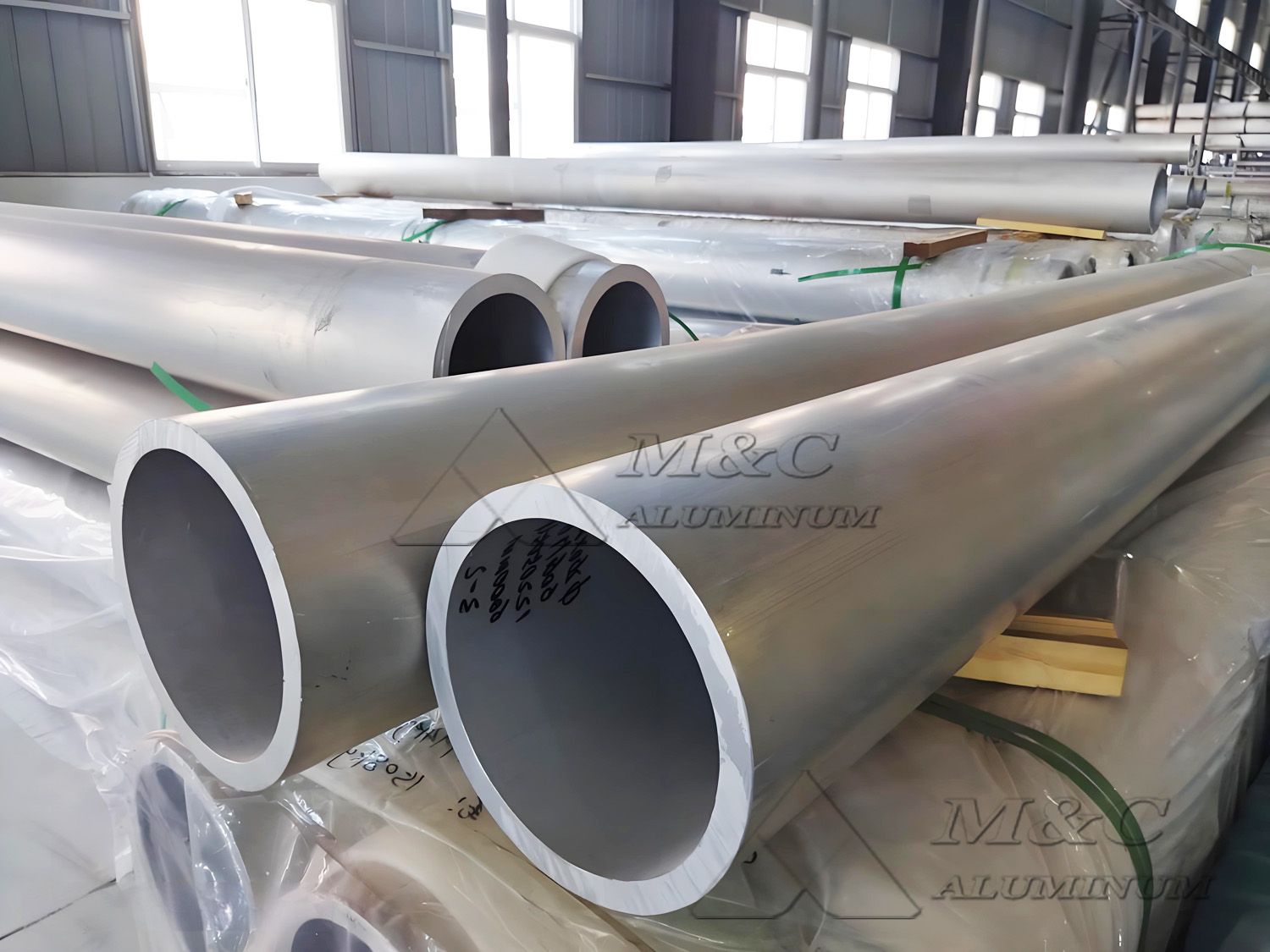

In demanding marine and industrial environments, 5083 marine-grade seamless aluminum tube stands out as an exceptional choice. Made from 5083 marine-grade aluminum and processed into various tempers such as O, H112, H116, and H321, it offers an outstanding balance of strength, corrosion resistance, and weldability, making it ideal for conditions beyond the reach of traditional materials.

In applications such as offshore platforms, ship hulls, and marine components, 5083 seamless aluminum tube effectively resists seawater corrosion and extends service life. Its seamless structure ensures tight sealing and high overall strength, enhancing the safety and stability of marine vessels. Additionally, the lightweight nature of 5083 marine aluminum helps reduce vessel weight, thereby decreasing fuel consumption and improving operational efficiency.

5083 Marine Aluminum Tube – Product Information

| Tempers | O, H112, H116, H321, etc. |

| Outer Diameter | Φ16mm - Φ350mm |

| Wall Thickness | 2mm - 30mm (customizable) |

| Length | Up to 8 meters, custom lengths available |

| Surface Options | Polished, anodized, or powder-coated (optional) |

| Manufacturing Method | Seamless extrusion or piercing (no welds) |

| Ovality | ≤0.3%D |

| Grain Size | ≥Grade 7 |

| Internal Defects | ≤Φ0.2mm |

| Standards | GB/T 4437.1, ASTM B241, DNV/BV classification society certifications (optional) |

| MOQ | 1-3 tons |

Mechanical Properties of 5083 H112 Seamless Aluminum Tube

| Property | Value |

| Tensile Strength | ≥270 MPa |

| Yield Strength | ≥125 MPa |

| Elongation (A50) | ≥10-12% |

| Hardness | 65-75 Brinell |

| Density | 2.66 g/cm³ |

| Corrosion Resistance | Excellent (seawater, chemicals) |

Key Advantages of 5083 Marine-Grade Aluminum Round Tube

1.Excellent Corrosion Resistance: Outstanding resistance to seawater, salt spray, and humid climates—ideal for offshore and marine environments.

2.High Strength-to-Weight Ratio: Strong yet lightweight, with good yield strength and fatigue resistance, significantly reducing structural weight and improving fuel efficiency.

3.Weldability and Workability: Compatible with TIG, MIG, and other welding methods. Easily processed for precision manufacturing and on-site assembly.

4.Low-Temperature Performance: Performs well in extremely low temperatures without becoming brittle, making it suitable for LNG tanks and other cryogenic applications.

How Is 5083 Seamless Aluminum Tube Manufactured?

5083 seamless aluminum tubes are commonly produced using hot extrusion or forging processes, following these general steps:

Billet Preparation

5083 aluminum ingots are forged or sawn into cylindrical billets suitable for extrusion.Homogenization (Optional)

To relieve internal stress and refine grain structure, billets may undergo high-temperature homogenizing treatment.Heating

Billets are heated to approx. 400–500°C to soften the material for extrusion.Hot Extrusion Forming

Under high pressure, the billet is forced through a mold with a mandrel, creating a hollow, seamless tube with near-final dimensions.Cooling & Cold Drawing (Optional)

After extrusion, tubes may undergo cold drawing to enhance dimensional accuracy and surface finish.Heat Treatment & Straightening

Some products receive age-hardening treatment to improve mechanical properties, followed by straightening to ensure tube alignment.

Typical Marine Applications of 5083 Seamless Tube

Drainage systems for yachts and naval/civil vessels

Hull structure supports and truss components

Hydraulic and oil transport systems on marine platforms

Cooling systems and seawater desalination equipment

Port construction and floating bridge structures

Chemical processing equipment and non-magnetic pipeline systems

Original Source: https://www.marinealum.com/a/5083-o-h112-marine-grade-seamless-aluminum-tube.html

Tag: Marine-grade extruded aluminum round tube seamless aluminum tube 5083 seamless aluminum pipe 5083 marine aluminum 5083 marine aluminum tube 5083 marine-grade pipe aluminum round tube marine aluminum alloy ER5356 welding wire aluminum profile mar