6061 aluminum alloy is a heat-treatable aluminum alloy primarily composed of magnesium (Mg) and silicon (Si). It offers medium strength, excellent corrosion resistance, superior weldability, and good machinability. In the shipbuilding industry, 6061 marine aluminum plates are widely used in structural parts, cabin panels, brackets, and decks, especially where both strength and corrosion resistance are required.

Tempers:

T6: Solution heat-treated and artificially aged. Offers high strength and good machinability; the most commonly used temper for structural applications.

T651: Stress-relieved version of T6 (typically via stretching), reducing the risk of deformation during machining or welding. Ideal for precision components requiring dimensional stability.

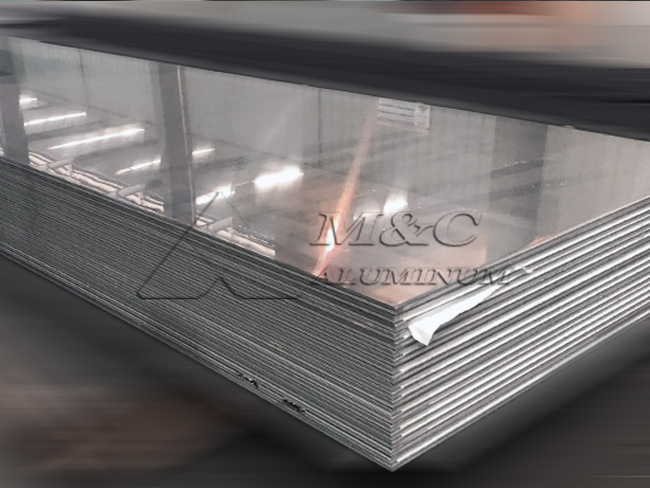

6061 Marine-Grade Aluminum Plate Specifications:

| Temper | T6, T651 |

| Thickness | 3 – 50 mm |

| Width | 1000 – 2650 mm |

| Length | 1000 – 16000 mm |

Mechanical Properties of 6061 T6 / T651 Marine Aluminum Plate

| Property | 6061-T6 | 6061-T651 |

| Tensile Strength | 290 – 310 MPa | 290 – 310 MPa |

| Yield Strength | ≥240 MPa | ≥240 MPa |

| Elongation (in 2") | 8 – 10% | 8 – 10% |

| Brinell Hardness | 95 HB | 95 HB |

| Modulus of Elasticity | ~69 GPa | ~69 GPa |

| Density | 2.70 g/cm³ | 2.70 g/cm³ |

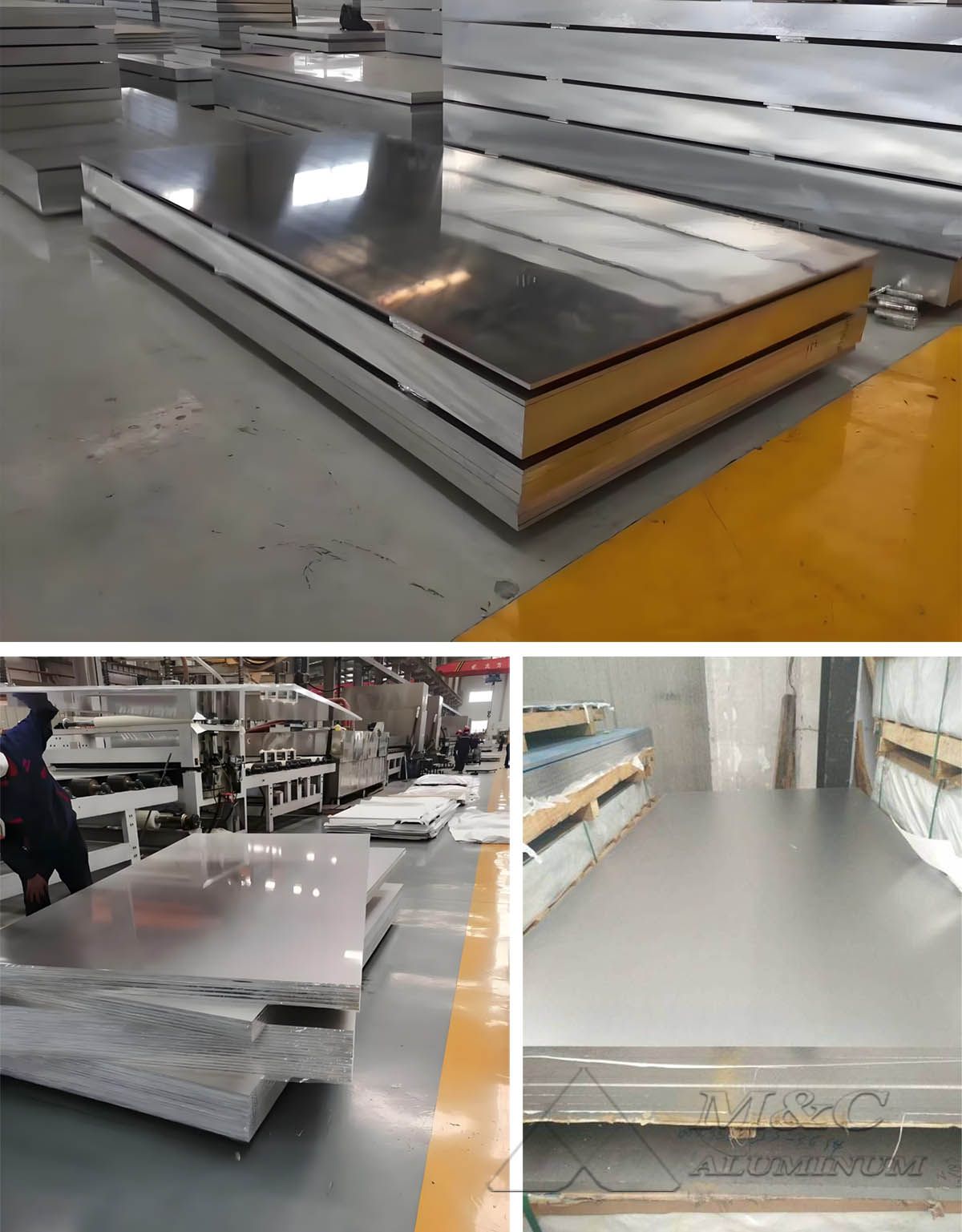

Performance Advantages of 6061 Marine-Grade Aluminum Plate

Excellent Resistance to Seawater Corrosion: Suitable for long-term use in humid and salt-spray environments.

Good Weldability: Compatible with TIG and MIG welding; resists cracking, ideal for complex marine components.

Medium to High Strength: Higher load-bearing capacity than pure aluminum or some 5xxx series alloys.

Superior Machinability and Dimensional Stability: Especially in T651 condition, ideal for CNC machining, drilling, and milling.

Lightweight and High Strength: About one-third the weight of steel, which improves fuel efficiency and payload ratio in ships.

Typical Marine Applications of 6061 Aluminum Plate

Structural reinforcements in hulls

Deck plating

Cabin partition panels

Marine brackets and frames

Ship ladders, gangways, and railings

Hull structures of speedboats and yachts

Comparison with Other Marine Aluminum Alloys

6061 vs. 5083: 6061 generally provides better strength and machinability after heat treatment, while 5083 offers superior corrosion resistance and better retention of strength after welding—often preferred for primary hull construction.

6061 vs. 5052: 6061 offers higher strength, whereas 5052 has excellent corrosion resistance and weldability, making it suitable for smaller boats and components.

Other Alloys:

6063: Often used for decorative and structural purposes.

7075: Very high strength but lower corrosion resistance and weldability—commonly used in aerospace rather than marine applications.