The deck is a critical structural component of a ship, forming the horizontal surface above the inner bottom and dividing the hull into layers. Decks, usually supported by ship beams, are exposed to heavy loads, environmental stress, and corrosion. Using 5052 aluminum plates for ship decks not only reduces weight and improves aesthetics but also provides excellent corrosion resistance.

5052 marine aluminum belongs to the Al-Mg alloy series, containing approximately 2.2%-2.8% magnesium. This composition provides high mechanical strength, excellent corrosion resistance against seawater, and light weight-making it ideal for small to medium ships, fishing boats, yachts, and offshore work platforms.

Performance of 5052 Aluminum Plates in Deck Applications

Corrosion Resistance:

Decks are constantly exposed to seawater and humid air, demanding exceptional corrosion resistance. The magnesium content in 5052 aluminum allows a dense oxide layer to form on the surface, effectively isolating the material from seawater and moisture. This reduces the risk of rust, ensuring structural stability and long service life.

Mechanical Performance:

5052 aluminum plates provide sufficient strength and toughness to withstand vibrations from navigation, as well as loads from personnel and cargo. This prevents deformation or cracking over time, maintaining the safety and reliability of the deck.

Workability:

The plates can be cut, bent, and shaped to fit specific deck dimensions and designs, simplifying installation.

Weldability:

5052 aluminum offers excellent weldability. Common welding methods like Gas Metal Arc Welding (GMAW) and Tungsten Inert Gas (TIG) welding can be applied, reducing manufacturing difficulty, improving production efficiency, and maintaining structural integrity.

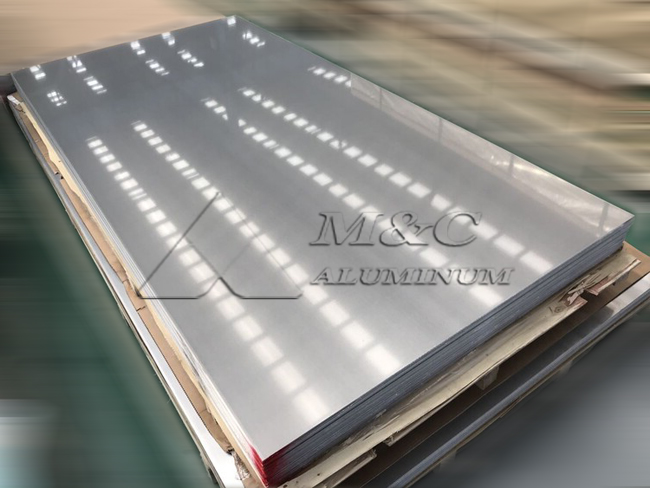

Specifications of Marine-Grade 5052 Aluminum Plates

| Alloy | 5052 |

| Temper | O, H12, H14, H16, H18, H19, H22, H24, H26, H28, H32, H34, H36, H38, H111, H112, H114, H116, H32 |

| Thickness Range | 3.0mm - 50mm |

| Width Range | 1000mm - 2000mm |

| Length | 1000mm - 16000mm |

| Tensile Strength | ≥210 MPa |

| Yield Strength | ≥130 MPa |

| Elongation | ≥10% |

| Typical Applications | Ship decks, bulkheads, bottom plating, side panels, interior panels |

| Packaging | Standard wooden crates |

| MOQ | 1-3 tons |

Applications of 5052 Marine Aluminum in Tempered Condition

For flat deck areas, H32 or H34 tempered aluminum sheets are suitable, offering high strength and the ability to withstand heavy loads.

For curved decks or areas requiring complex forming, O tempered (annealed) aluminum sheets are recommended, offering the best formability.

For applications requiring both strength and good formability, H111 or H112 tempered sheets are suitable for hot forming processes.

Comparison with Other Marine Aluminum Alloys

5052 vs 5083: 5083 aluminum sheet contains more magnesium (4.0-4.9%) than 5052, resulting in higher strength and better corrosion resistance. However, 5083 is more difficult to form, while 5052 is easier. For most marine deck applications, 5052 strikes a better balance between performance and cost.

5052 vs 6061: 6061 marine aluminum, after heat treatment, has higher strength than 5052, but its corrosion resistance is not as good, especially in marine environments. 5052 has a higher magnesium content, making it superior in resistance to saltwater corrosion.

Price of Marine-Grade 5052 Aluminum Plates

The price of 5052 marine aluminum plates depends on the daily aluminum ingot price, shipping costs, processing fees, thickness, and alloy temper. For an accurate quote, provide the alloy temper, thickness, and length via email. Professional customer service will respond with detailed pricing information.

Original Source: https://www.marinealum.com/a/5052-aluminum-plate-for-ship-decks.html

Tag: Marine-grade 5052 aluminum plate 5052 aluminum plate ship aluminum plate 5052 marine aluminum deck aluminum plate 5052 H32 aluminum plate marine alloy plate ocean-grade aluminum plate marine aluminum manufacturer