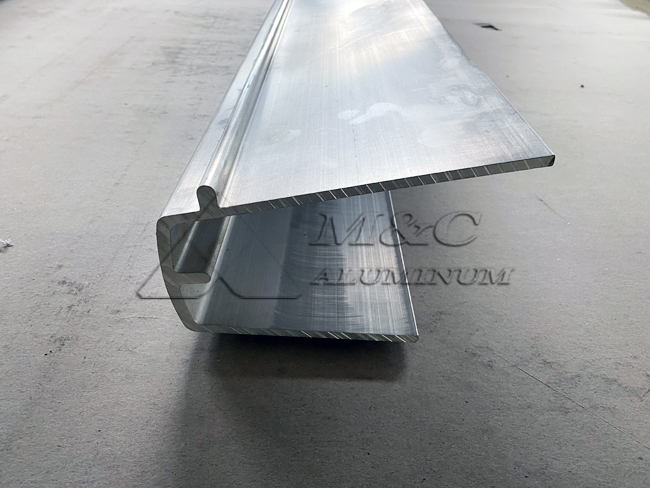

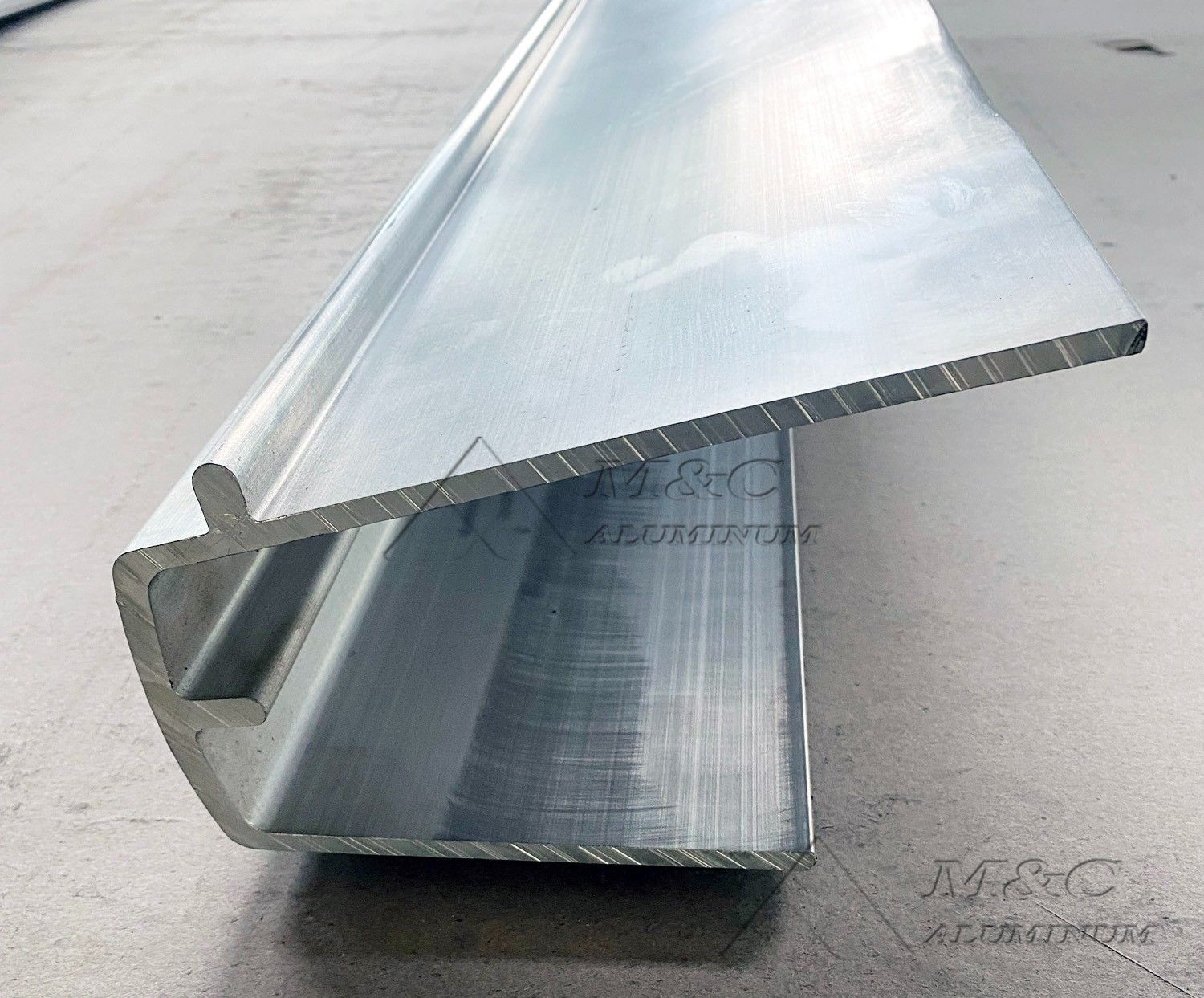

What Is a Marine Fender Plate?

A marine aluminum fender is a lateral protective panel installed on the side of a ship. Typically made of aluminum alloy or steel plate, it plays a crucial role in protecting the hull during navigation. It helps absorb impact and reduce damage caused by collisions with docks or other vessels, thereby preserving the integrity and strength of the ship's structure. Additionally, marine fender plates can enhance the structural strength of the hull to withstand harsh marine environments such as wind and waves.

In shipbuilding, 5083-H116 aluminum alloy is commonly used for the hull plates, while 6061-T6 aluminum alloy is used for structural profiles. This highlights the role of 6061-T6 as a key material for structural supports and frameworks rather than for exterior hull plating.

Features of 6061-T6 Aluminum Fender

These aluminum fenders are made from marine-grade 6061-T6 aluminum alloy, which is surface-anodized for enhanced durability. This alloy is widely used in ship components such as gangways, fenders, and ladders.

Functions of Aluminum Fenders:

1. Hull Protection: Fenders effectively shield the hull from damage during berthing or collisions with other vessels.

2. Extended Service Life: Thanks to the corrosion resistance of 6061-T6, these fenders remain in good condition even in harsh marine environments, reducing maintenance frequency and long-term costs.

3. Weight Reduction: Lightweight fenders help reduce the overall weight of the vessel, improving speed, fuel efficiency, and cargo capacity.

4. Customizable: The excellent machinability of 6061-T6 allows for custom-made fenders to fit various ship dimensions and shapes.

Why Choose 6061-T6 Aluminum Alloy?

1. High Strength-to-Weight Ratio: T6 heat treatment delivers strength comparable to steel at a fraction of the weight, improving vessel fuel efficiency and performance.

2. Excellent Corrosion Resistance: Performs well in marine environments by forming a protective oxide layer that prevents corrosion, significantly extending service life.

3. Great Machinability and Weldability: Easy to cut, drill, and form—ideal for fender manufacturing. Compatible with various welding methods such as TIG, MIG, and arc welding.

4. Durability: Strong toughness and wear resistance enable it to withstand impacts and abrasions in marine conditions.

5. T6 Heat Treatment: Involves solution heat treatment and artificial aging to enhance strength and hardness.

Applications of Marine Aluminum Fenders

Large Ports and Docks:

Aluminum fenders are widely used at major port terminals, providing protection for various types of ships.Yacht Marinas:

Commonly installed at yacht marinas, these fenders ensure a safe and reliable docking environment.Other Vessel Types:

Aluminum fenders can also be applied to a wide range of vessels including cargo ships, passenger ships, and more.

As a large marine aluminum manufacturer, MC Aluminum provides 5 series and 6 series marine aluminum alloys, including marine aluminum plates, marine aluminum profiles, pipe fittings, aluminum-steel composite plates and other products that can be used in shipbuilding. Our products are of excellent quality, huge production capacity, short delivery time, exported to many overseas countries, and at preferential prices. We welcome new and old customers to visit our factory.