Overview of 5083 Marine Aluminum Alloy

5083 aluminum alloy belongs to the Al-Mg (5xxx series) system, with a magnesium content of about 4.0-4.9%, and small amounts of manganese and chromium. This alloy cannot be strengthened by heat treatment; instead, it achieves higher strength mainly through strain hardening (cold working).

5083 is an internationally recognized marine standard aluminum alloy, widely used in ship hulls, decks, cabins, and other critical components.

Key advantages of 5083 marine aluminum plates:

Excellent seawater corrosion resistance – far superior to most steels and some 6xxx series aluminum alloys.

High strength – stronger than 5052 and 5754, making it more suitable for high-load ship structures.

Good weldability:retains good mechanical properties after welding.

Outstanding low-temperature toughness:maintains ductility even at -196°C.

Lightweight:reduces overall vessel weight, improves speed, and helps lower fuel consumption.

H116 vs. H321: Tempers Designed for Marine Environments

In marine applications, 5083 plates are often supplied in H116 or H321 temper conditions. These are not random designations, but rather specific states tailored for the harsh marine environment.

H116 Temper

Specially designed for marine service. Through controlled strain hardening and thermal processing, H116 achieves high strength with excellent resistance to exfoliation corrosion (a severe grain-boundary corrosion threatening aluminum structures in seawater). This ensures long-term structural safety for hulls in direct seawater exposure.

H321 Temper

A slightly harder temper compared to H116. It undergoes strain hardening followed by low-temperature stabilization treatment, delivering both high strength and superior stress corrosion cracking resistance. H321 plates are often chosen for higher-load areas such as decks and superstructures.

Marine Grade 5083 Aluminum Plate – Product Specifications

| Temper | 5083 H321 / H116 |

| Thickness | 3 mm - 50 mm |

| Width | 1,000 mm - 2,600 mm |

| Length | 2,000 mm - 12,000 mm |

| Standard sizes | 2000×6000 mm, 2000×8000 mm, 2000×9000 mm, 1500×3000 mm |

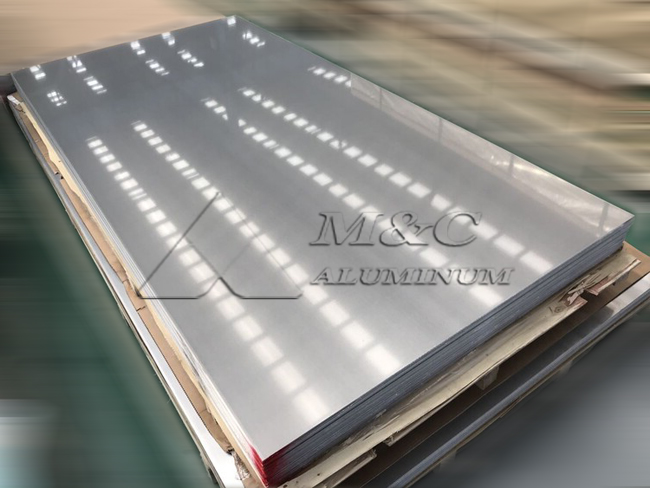

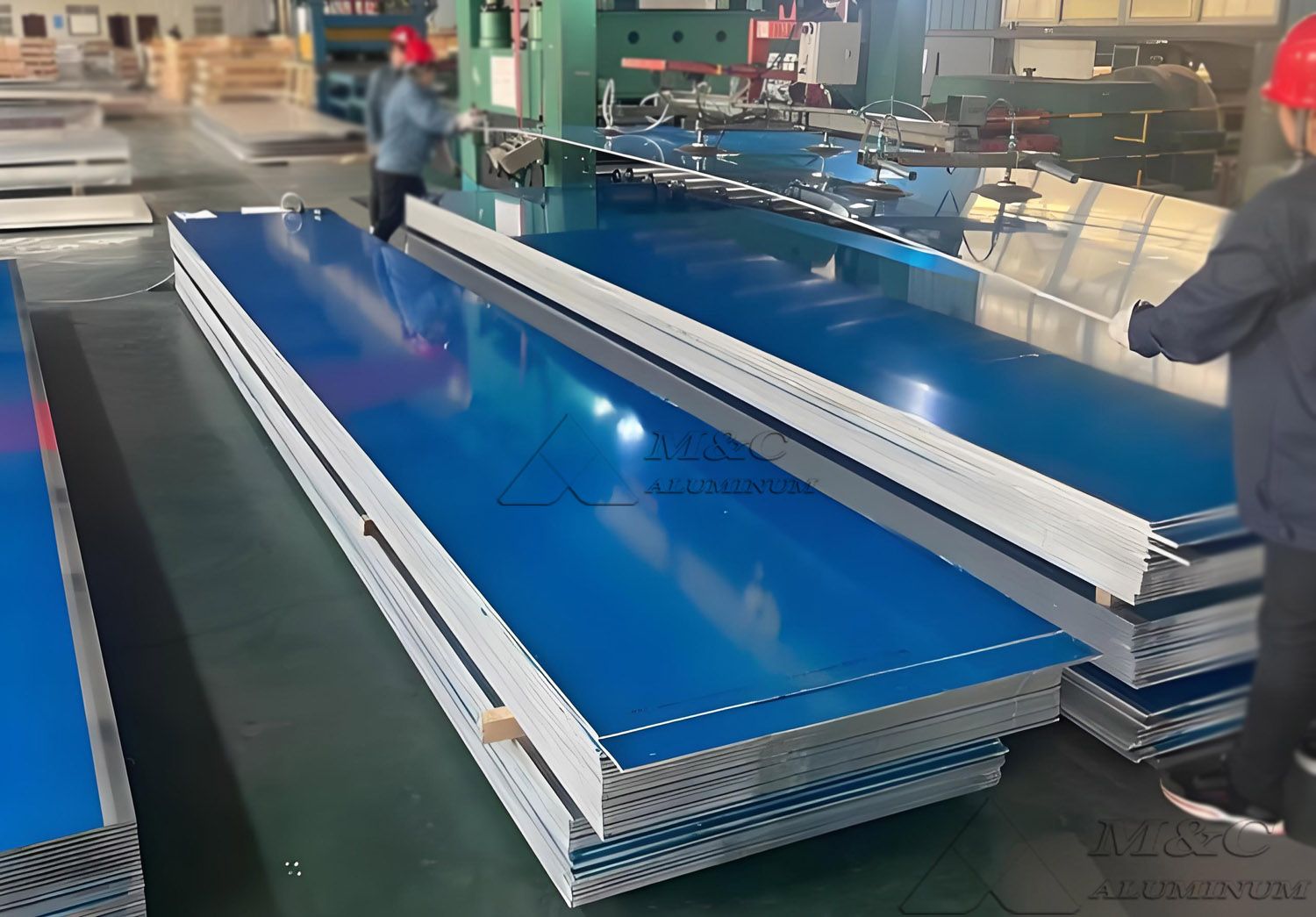

| Surface finish | Mill finish, bright finish, polished |

| Protective film | Blue PVC film or paper interleaving |

| Packaging | Standard airworthy packaging |

| MOQ | 1-3 tons |

Mechanical Properties of 5083 Marine Aluminum Plates

| Temper | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) |

| 5083-H111 | 272 | 143 | 14 |

| 5083-H112 | 294 | 157 | 10 |

| 5083-H116 | 315 | 226 | 10 |

| 5083-H321 | 315 | 226 | 10 |

Applications of 5083 Marine Aluminum Plates

Ship Hull Structures

Used in hull plating, decks, side shells, and bottom plates – all areas that are in constant contact with seawater.

Internal Facilities

Applied in consoles, engine bases, cable trays, and other onboard components. The lightweight feature of aluminum lowers the vessel’s center of gravity, improving stability.

Specialty Vessels

Extensively applied in yachts, cruise ships, grain carriers, fishing vessels, workboats, and dredgers.

Importance of Classification Society Certificates

CCS (China Classification Society): China’s official classification authority.

DNV (Det Norske Veritas): Norway’s classification society, known for its expertise in offshore oil, gas, and renewable energy.

ABS (American Bureau of Shipping): The U.S. classification society, with strong influence in offshore engineering and LNG carriers.

BV (Bureau Veritas): France-based, globally recognized for inspection and certification services.

LR (Lloyd’s Register): UK-based, one of the world’s oldest and most prestigious classification societies.

Certification guarantees that:

The alloy’s chemical composition and mechanical properties comply with marine standards.

The production process is controlled and quality is traceable.

The plates are ready for direct use in shipbuilding without additional testing.

The material is globally accepted for export and international ship projects.

If you plan to use 5083 H116 / H321 marine aluminum plates for shipbuilding or offshore projects, obtaining approval from at least one major classification society (CCS, DNV, ABS, BV, or LR) is mandatory to ensure compliance and reliability.

Original Source: https://www.marinealum.com/a/5083-h116-h321-aluminum-plates-with-ccs-dnv-abs-bv-lr-certificates-for-shipbuilding.html

Tag: 5083 marine grade aluminum plate 5083 H116 marine aluminum plate 5083 H321 marine aluminum plate 5083 aluminum plate 5 series marine aluminum alloy marine grade aluminum plate 5083 H116/H321 aluminum plate marine aluminum supplier