In modern shipbuilding and offshore engineering, piping systems are often referred to as the "blood vessels" of a vessel. Whether it is a deepwater drilling platform or an ocean-going cargo ship, materials are directly linked to operational safety and service life when exposed to high-salinity, highly corrosive environments. Among the many material options, 5083 aluminum alloy flanges, particularly 5083 O temper aluminum alloy flanges, have become an excellent solution for the design and upgrading of modern ship piping systems due to their comprehensive performance.

Why 5083 Aluminum Alloy Flanges Are Preferred for Ship Piping

5083 belongs to the Al-Mg high-magnesium aluminum alloy series. It does not require heat treatment for strengthening, yet in the annealed (O temper) condition, it maintains excellent overall properties, making it highly suitable for marine environments.

1. Excellent Seawater Corrosion Resistance

5083 aluminum alloy exhibits strong resistance to seawater, salt spray, and various chemical media. It is less prone to pitting or intergranular corrosion during long-term service, making it a mature and reliable material for ship structures and piping systems.

2. Significant Weight Advantage

Compared to carbon steel or stainless steel flanges, 5083 aluminum alloy flanges are much lighter. This helps reduce the overall weight of the vessel and improves fuel efficiency, especially beneficial for high-speed ships, specialized vessels, and offshore equipment.

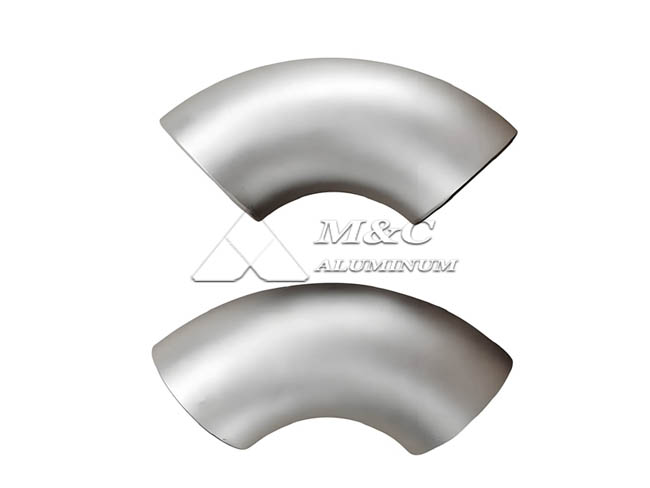

3. Good Weldability and Machinability

5083 O temper flanges have excellent ductility and low susceptibility to welding cracks, allowing easy welding connections with aluminum alloy pipes. This makes them suitable for installation and maintenance in complex ship piping networks.

Why O Temper Is the Best Choice for Marine Piping

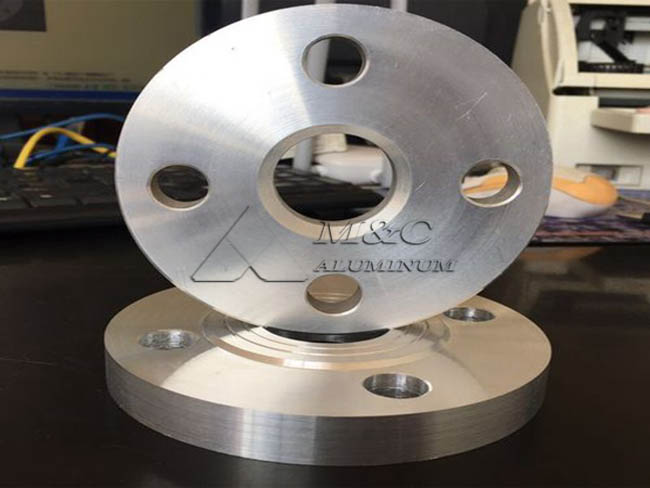

1. Elimination of Residual Stress

During forging or machining, flanges develop internal stress. Annealing to O temper fully relieves these stresses, ensuring the flange does not deform during long-term service and maintains tight pipe connections.

2. Excellent Ductility and Processing Performance

O temper aluminum alloy has outstanding plasticity. In complex ship piping layouts, flanges require precise welding and assembly. O temper material not only provides excellent weldability but also absorbs mechanical vibration or pressure impact with better toughness, reducing the risk of brittle fracture.

Chinese 5083 Flange Manufacturers

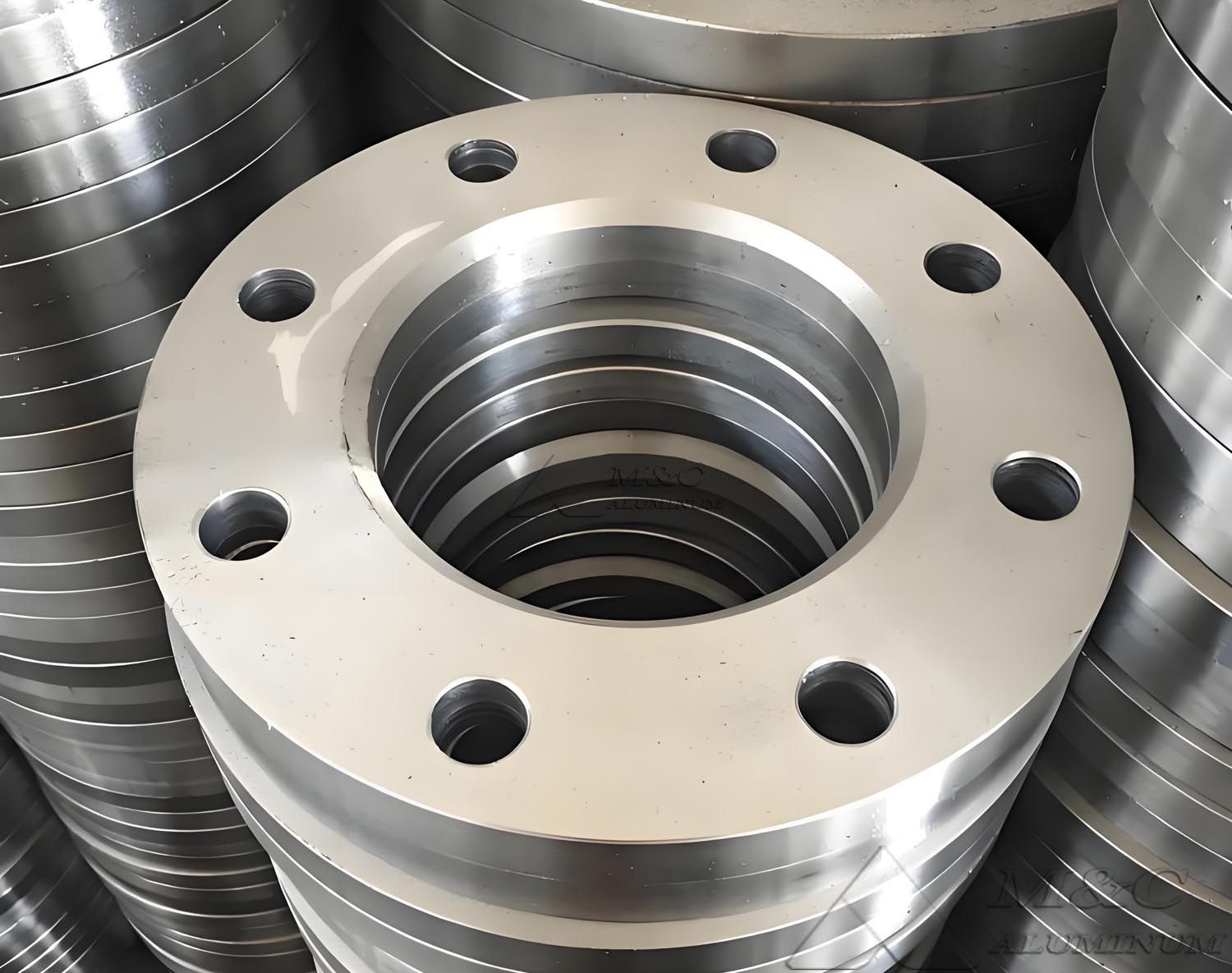

Flange Standards

ANSI / ASME Standards: ANSI B16.5, MSS-SP-44, DIN EN 1092-1 PN6, PN16, PN16 Flanges

5083 Aluminum Alloy Slip-On Flanges:

DIN 2576 PN10 Slip-On Flange / EN 1092-1 Type 01 Slip-On Flange

DIN 2576 PN10 5083 Flange, DIN 2576 PN10 5083 Slip-On Flange

5083 Aluminum Alloy Weld Neck Flanges:

5083 Socket Weld Flange ASME B16.5

Other available alloys

5083 H116 flanges, 5083 H32L aluminum alloy flanges, 5052 aluminum alloy flanges, 6063 aluminum alloy flanges, and 6063 T6 aluminum flanges.

5083 Flanges Compliant with DIN Plate Flange Standards

DIN 2573 PN6 5083 Flange

DIN 2576 PN10 5083 Flange

DIN 2501 PN10 Flange

DIN 2501 PN16 Flange

DIN 2502 PN16 Flange

DIN 2503 PN25 Flange

DIN 2503 PN40 Flange

DIN 2543 PN16 Flange

Advantages Compared to Traditional Materials

| Comparison | Advantages of 5083 Aluminum Flange |

| vs. Carbon Steel Flanges | No heavy galvanization required, completely avoids rusting, lower lifecycle cost, significant weight savings |

| vs. Other Aluminum Alloys | Higher strength than pure or low-magnesium alloys; better corrosion resistance and weldability than high-strength 2XXX or 7XXX series; well-balanced overall properties |

| vs. Stainless Steel Flanges | Lightweight, cost-effective, non-magnetic while maintaining comparable corrosion resistance |

Applications of 5083 Marine Aluminum Flanges in Piping Systems

Seawater Systems: Cooling water, ballast water, fire water, and other pipelines in direct contact with seawater. Their corrosion resistance significantly extends service life and reduces maintenance frequency.

Oil & Gas Pipelines: Connections for fuel, lubricating oil, and low-pressure oil and gas lines. Non-magnetic and spark-resistant properties enhance safety.

HVAC Systems: Lightweight design reduces superstructure weight and simplifies installation.

Specialized Vessels: Used on LNG carriers, chemical tankers, and other high-end ships due to excellent low-temperature tolerance and resistance to specific chemical media.