In modern shipbuilding and offshore engineering, flanges are critical connection components in piping systems. Their material selection, mechanical strength, and corrosion resistance have a direct impact on vessel safety, operational reliability, and service life.

6061 T6 aluminum alloy butt weld neck flanges, with their lightweight structure, high strength, and excellent corrosion resistance, have become one of the preferred solutions for marine pipelines, ship hydraulic systems, and seawater handling systems.

6061-T6 Weld Neck Flange

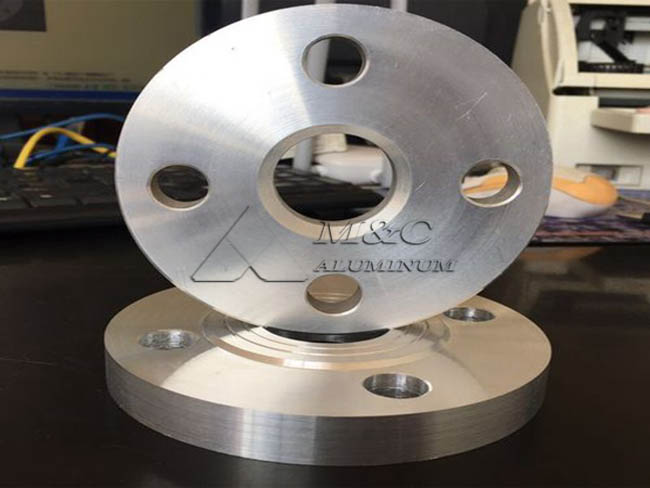

The 6061-T6 weld neck flange is a robust aluminum piping connector-typically manufactured in accordance with ASTM B247-designed to provide secure, leak-free connections in piping systems. It is especially suitable for applications requiring corrosion resistance and weight reduction, such as high-vacuum systems and chemical environments.

The T6 heat treatment provides excellent mechanical strength. Unlike standard slip-on or flat welding flanges, weld neck flanges feature a long tapered hub and are connected to pipes via butt welding, effectively transferring stress into the pipe wall. This design enables higher pressure resistance and elastic performance.

They are available in a wide range of sizes (1/2 inch to 24 inches) and pressure classes (e.g., Class 150).

Butt Weld Neck Flange: Engineered for Demanding Operating Conditions

The weld neck flange is the preferred connection type for high-pressure, high-temperature, and high-reliability piping systems. Its structural characteristics make it ideally suited for marine applications:

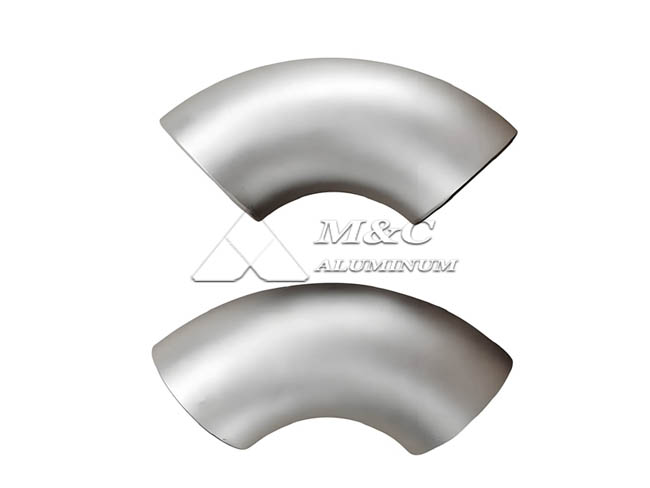

1.Long Tapered Hub Design

The neck is butt-welded to the pipe, creating a smooth stress transition from pipe to flange. This significantly reduces stress concentration and is particularly suitable for cyclic loads and vibrations caused by waves and vessel motion.

2.High-Strength Connection

The butt weld joint achieves strength equivalent to the pipe base material, ensuring high joint efficiency and system integrity. It fully meets the stringent safety requirements of marine propulsion systems, ballast systems, and fire-fighting pipelines.

3.Excellent Flow Characteristics

The smooth internal bore transition (matched to pipe ID) minimizes turbulence and pressure drop while preventing sediment accumulation-critical for fuel oil, lubricating oil, and seawater systems on board vessels.

6061 T6 Marine Weld Neck Flange - Key Advantages

1.Outstanding Corrosion Resistance

Naturally forms a dense oxide layer that effectively resists salt spray and seawater corrosion, reducing the need for frequent coatings.

2.Significant Weight Reduction

With a density only one-third that of steel, aluminum flanges greatly improve vessel payload capacity, cruising speed, and fuel efficiency.

3.Vibration and Crack Resistance

The necked design disperses welding stress, allowing the flange to withstand continuous vibration and pressure fluctuations during navigation.

4.Stable Performance

Excellent weldability, good low-temperature toughness (no brittle transition), and non-magnetic properties ensure operational safety in marine environments.

Technical Parameters of Marine Aluminum Flanges

| Material | 6061 Aluminum Alloy |

| Temper | T6 |

| Flange Type | Butt Weld Neck Flange (BW) |

| Standards | ASME B16.5 / EN 1092-1 / GB/T 12224 |

| Size Range | DN15–DN600 (customizable) |

| Pressure Rating | PN16 / PN25 / Class 150 / Class 300 |

| Outside Diameter (OD) | As per standard flange dimensions |

| Thickness / Facing | Per ASME / EN / GB standards, customizable |

| Tensile Strength | 290-310 MPa |

Yield Strength | ≥ 240 MPa |

| Elongation | 8-12% |

| Hardness (HB) | 95-105 |

| Weldability | Fully weldable, suitable for pipe butt welding |

| Corrosion Resistance | Superior to carbon steel, excellent in seawater and chloride environments |

| Surface Treatment | Anodizing, anti-corrosion coating (optional) |

| Applicable Pipelines | Marine hydraulic systems, cooling water lines, seawater treatment pipelines, fuel systems |

| Supply Form | Finished flanges / OEM customized products |

Marine Flange Quality Standards

Forging Process

High-quality flanges are typically produced by die forging, ensuring continuous metal flow lines and dense microstructure. Forged flanges offer superior mechanical properties compared with cast flanges.

Precision Machining

CNC machining guarantees high surface finish and dimensional accuracy of sealing faces (e.g., Raised Face (RF), Ring Type Joint (RTJ)), as well as precise bolt hole positioning, ensuring leak-free assembly.

Non-Destructive Testing

100% penetrant testing (PT) or ultrasonic testing (UT) is performed to detect cracks, laminations, or internal defects.

Certification Systems

Products can be certified by major classification societies such as CCS, ABS, DNV, and LR, ensuring full traceability and compliance from raw material to finished product.

Application Scenarios of 6061 T6 Aluminum Alloy Butt Weld Neck Flanges

Marine piping systems: cooling water, fuel oil, and hydraulic pipelines

Seawater treatment systems: pump stations and filtration units

Marine mechanical connections: high-pressure hydraulic interfaces

Luxury yachts and offshore equipment: lightweight structures to reduce overall vessel weight

Original Source: https://www.marinealum.com/a/6061-t6-aluminum-alloy-butt-weld-neck-flange-marine-grade.html

Tag: 6061-T6 aluminum flange marine aluminum flange piping fittings 6061 aluminum flange weld neck flange raised face flange ASME aluminum flange aluminum alloy flange supplier marine flange connection