In harsh marine engineering environments, every joint in a piping system is critical. As a key component for marine piping connections, 5083 aluminum threaded flanges have become a preferred choice for modern shipbuilding, offshore platforms, and port facilities thanks to their outstanding performance.

What Is a Threaded Flange?

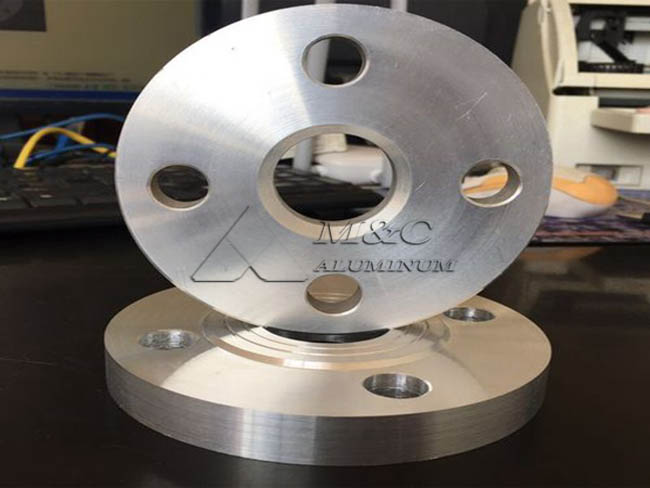

A threaded flange (also called a screwed flange) is a type of flange with internal threads machined in the bore, allowing it to connect directly to a pipe with external threads. Welding is typically not required (though seal welding may be added in certain applications).

Connection method: A flanged joint is a detachable sealing structure consisting of a flange, gasket, and bolts, making installation, maintenance, and inspection convenient.

Marine use: 5083 aluminum threaded flanges are widely used in fluid transport systems on ships, offshore platforms, and other marine equipment, such as ballast water systems, fuel systems, and ventilation systems.

Standards & specifications: Marine flanges are usually manufactured to specific national standards (GB), industry standards (CB), or classification society rules (e.g., ABS, DNV, CCS) to ensure interchangeability and safety.

Why Choose 5083 Aluminum Alloy?

5083 is an Al-Mg (aluminum-magnesium) alloy and a typical marine-grade aluminum alloy, offering key advantages:

Excellent corrosion resistance: Highly stable in seawater and industrial atmospheres, effectively resisting pitting corrosion and stress corrosion cracking.

Good weldability and strength: Even after welding, 5083 retains good tensile strength, ensuring the structural integrity of piping systems.

Lightweight advantage: Aluminum density is only about one-third that of steel, significantly reducing vessel weight and improving sailing efficiency and payload capacity.

Technical Specifications of 5083 Aluminum Threaded Flanges

| Parameter | Technical Requirement |

| Alloy | 5083 |

| Temper | H116, H321 |

| Standards | ANSI B16.5, EN 1092-1, JIS B2220, etc. |

| Common sizes | 1/2"-24" (DN15–DN600) |

| Pressure rating | Class 150, Class 300, PN10, PN16 |

| Condition | H111, H112, H116, O temper |

| Thread type | NPT (US taper thread), BSPP/BSPT (British standard) |

| MOQ | 1-3 tons |

Unique Value of Threaded Flanges in Marine Piping

Compared with welded flanges, threaded flanges offer irreplaceable advantages in certain shipboard applications:

No welding required, higher safety: For retrofit or maintenance areas where open flames are strictly prohibited (e.g., sensitive zones on oil tankers and chemical carriers), threaded connections are safer.

Fast and efficient installation: Especially suitable for small-bore piping systems, greatly shortening construction time.

Lower maintenance cost: Threaded joints are easy to disassemble, facilitating later cleaning, inspection, and replacement.

How to Select High-Quality Aluminum Flanges

1.Standards and certifications are essential

Quality products should comply with relevant requirements from ISO, ASTM, DNV-GL, LR, ABS, and other classification societies. When purchasing, confirm the availability of material certificates (3.1 or 3.2), temper/heat treatment reports, and dimensional inspection reports.

2.Surface treatment for enhanced protection

Depending on requirements, choose anodizing (to increase surface hardness and wear resistance) or marine-grade coating systems to provide dual-layer protection.

3.Precision thread machining

Threads must comply with ISO 228 (G series) or ANSI/ASME B1.20.1 (NPT series) to ensure global compatibility with valves and fittings. Complete thread profiles and burr-free machining are fundamental to preventing leaks.

4.Pressure-temperature rating

Note that the rated pressure of aluminum alloy flanges decreases as temperature increases. Selection must reference the manufacturer’s P–T rating chart to ensure pressure requirements are met at the system’s maximum operating temperature.

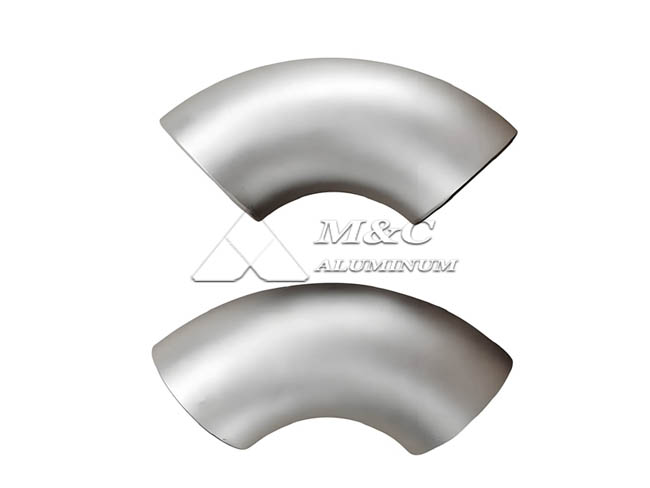

Typical Applications of 5083 Aluminum Flanges

Seawater desalination and circulation systems: Leveraging strong seawater corrosion resistance.

Fuel and lubricating oil pipelines: Providing reliable sealed connections.

Ballast water treatment systems: Ensuring long-term operational stability.

Auxiliary power unit (genset) piping systems.

FAQ

Q1: Is 5083 aluminum alloy suitable for high-temperature systems?

A: Yes. 5083 performs stably below 150°C. For higher temperatures (>200°C), 5083-H321 or 6061 aluminum alloy is recommended.

Q2: What is the difference between a threaded flange and a flat (plate) flange?

A: A threaded flange connects via internal threads and is generally used for small-bore piping (DN ≤ 100). A flat flange seals through the flange face and is commonly used for larger diameters (DN > 100).

Q3: How can the service life of 5083 aluminum flanges be extended?

A:

Inspect flange faces and coatings regularly for damage;

Use flanges with anti-corrosion coatings;

Avoid long-term operation in high-vibration environments;

Re-tighten bolts periodically.

Q4: Can 5083 aluminum flanges be used in seawater cooling systems?

A: Yes. However, a dual-layer coating system (outer anti-corrosion coating + inner chloride-barrier coating) is recommended to improve seawater corrosion resistance.

Original Source: https://www.marinealum.com/a/5083-aluminum-threaded-flanges-for-marine-piping.html

Tag: 5083 aluminum flange marine aluminum flange threaded flange welded flange 5083 marine-grade aluminum 5083 H116 aluminum flange 5083 H321 aluminum flange pipe fittings aluminum alloy flange supplier marine flange connectors