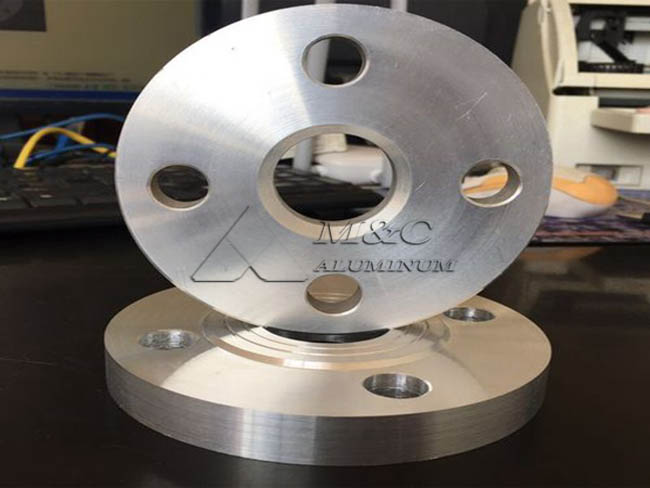

In marine engineering, the corrosion resistance and mechanical strength of flanges directly determine the safety and reliability of ship piping systems. Although stainless steel flanges are widely used, aluminum alloy flanges are increasingly favored in modern shipbuilding due to their lightweight nature, excellent thermal conductivity, and outstanding resistance to seawater corrosion when the right alloy is selected.

Aluminum flanges manufactured by MC Aluminum are certified by major classification societies, including DNV-GL, ABS, LR, and CCS, ensuring full compliance with international marine standards.

Performance Advantages of Marine Aluminum Flanges

1. Significant Weight Reduction

The density of aluminum alloy is approximately one-third that of steel. Using aluminum flanges can effectively reduce the weight of piping systems, making them particularly suitable for high-speed vessels, yachts, and special-purpose ships.

2. Excellent Resistance to Marine Corrosion

Specific marine-grade aluminum alloys form a stable and protective oxide film in seawater and salt-spray environments, significantly reducing the risk of pitting and crevice corrosion.

3. Good Machinability and Weldability

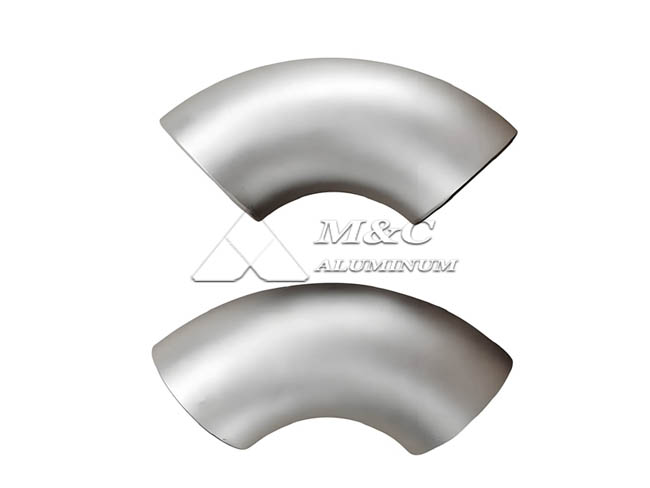

Aluminum alloy flanges are easy to forge, machine, and weld, making them ideal for producing weld neck flanges, slip-on flanges, and customized non-standard flanges.

4. Comprehensive Cost Advantages

From a full life-cycle perspective, aluminum flanges offer low maintenance costs and long service life, providing strong overall economic value.

Most Suitable Aluminum Alloy Grades for Marine Flanges

5083 Aluminum Alloy – The Backbone for Marine Applications

5083 is an Al-Mg alloy with a magnesium content of 4.0-4.9%, making it a true marine-grade material. Its tensile strength reaches 275-350 MPa, with a yield strength of 125-200 MPa, fully meeting classification society requirements.

Corrosion Resistance:

One of the best aluminum alloys for seawater resistance, forming a highly durable protective layer in salt spray and humid environments.Weldability:

Excellent weldability with high post-weld strength, making it ideal for ship piping systems that require on-site welding.Typical Tempers:

H111, H112, H116. Among them, H116 offers outstanding resistance to exfoliation corrosion and is the preferred choice for high-end marine flanges.

5086 Aluminum Alloy – A Balanced Option

5086 has a composition similar to 5083 but with slightly lower magnesium content (3.5-4.5%). While maintaining strong corrosion resistance, it provides better formability, making it especially suitable for flanges requiring cold bending or complex shaping.

6061 Aluminum Alloy – Precision Structural Applications

6061 is an Al-Mg-Si alloy that can achieve high strength through T6 heat treatment, with tensile strength exceeding 310 MPa. Its key advantage lies in excellent machinability, making it ideal for flanges with complex geometries and tight tolerances.

Although 6061 shows slightly lower corrosion resistance than 5083/5086 in fully immersed seawater conditions, it performs exceptionally well in atmospheric zones (above deck). After anodizing, both hardness and corrosion resistance are significantly improved. It is commonly used in upper-deck piping systems and instrument pipeline flanges where precision is critical.

Marine Aluminum Flanges: 5083 & 5086 & 6061

| Performance Index | 5083-H116 | 5086-H116 | 6061-T6 |

| Tensile Strength (MPa) | 275-350 | 240-330 | 310-350 |

| Yield Strength (MPa) | 125-200 | 110-200 | 275-310 |

| Elongation (%) | 12-16 | 10-14 | 8-12 |

| Hardness (HB) | 70-85 | 65-80 | 95-100 |

| Seawater Corrosion Rate (mm/year) | 0.03-0.05 | 0.04-0.06 | 0.05-0.08 |

| Weld Efficiency | 0.92-0.95 | 0.90-0.94 | 0.75-0.85 |

| Thermal Expansion (×10⁻⁶/°C) | 23.8 | 23.8 | 23.6 |

| Relative Cost Index | 1.0 | 0.95 | 1.1 |

How to Choose the Right Marine Aluminum Alloy Flange

1.Operating Environment

If the flange is used in seawater cooling systems or directly exposed to marine environments, 5083-H116 or H112 is strongly recommended. Its high magnesium content effectively mitigates electrochemical corrosion.

2.Pressure Requirements

For high-pressure hydraulic piping systems with stringent strength demands, 6061-T6, combined with surface hardening treatments, provides a more reliable solution.

3.Installation Method

For weld neck (WN) or socket weld (SW) flanges, 5083 is preferred.

For threaded or lap joint flanges, 6061 offers superior machining performance.

Original Source: https://www.marinealum.com/a/the-most-suitable-aluminum-alloys-for-marine-flanges.html

Tag: aluminum flange marine aluminum flange pipe fittings marine aluminum alloy flange 5083 aluminum flange 6061 T6 aluminum flange 5086 aluminum flange marine piping fittings aluminum alloy flange