MC Aluminum, as a professional marine aluminum manufacturer, produces a wide range of pipe fittings, including 5086 H32 and 6061 T6 aluminum alloy fittings, aluminum elbows (90° short radius, 45° long radius, 180° long radius, 90° short radius, 180° short radius), tees (straight and reducing), crosses (straight and reducing), aluminum fittings pipe caps, and aluminum flanges. We also offer customized pipe fittings to meet specific requirements.

Aluminum flanges are made from aluminum alloys such as 5052, 5083, or 6061, and are manufactured through machining or casting processes. They serve as essential pipeline connectors in marine and shipbuilding industries. Compared to traditional steel flanges, aluminum flanges offer lightweight, corrosion resistance, high strength, and easy machinability, making them ideal for marine equipment and ship applications.

Marine aluminum flanges are commonly produced using forging processes. Forged flange blanks have smooth surfaces, providing a solid foundation for subsequent precision machining.

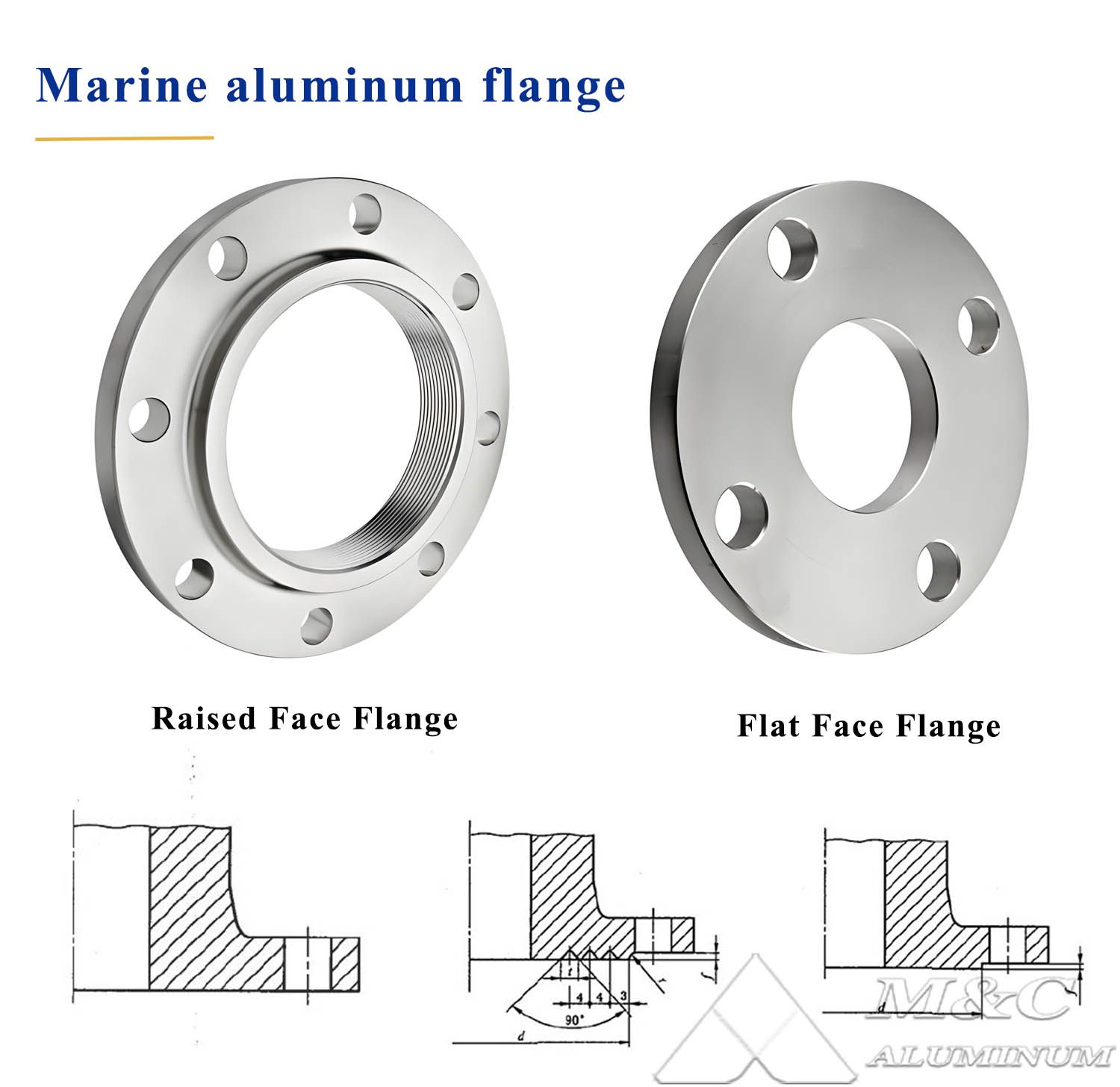

Common Types of Marine Aluminum Flanges

Flat Face Flange (FF)

1. Structural Features:

The flange sealing surface is on the same plane as the bolt holes, resulting in a completely flat surface.

2. Sealing Method:

Typically used with full-face gaskets, which cover the entire flange surface, including the bolt hole area.

3. Application Scenarios:

Low-Pressure Systems: Ideal for low-pressure, low-risk pipelines.

Connection to Cast Iron or Non-Metallic Flanges: Flat face flanges reduce stress concentration, preventing brittle flanges from cracking.

Easy Maintenance: Simple structure allows for easy installation and removal.

Raised Face Flange (RF)

1. Structural Features:

The flange sealing surface is slightly raised above the surrounding bolt hole area, typically by 1/16 inch or 1/4 inch.

2. Sealing Method:

Used with ring gaskets, which are applied only to the raised sealing surface. The bolt pre-load is concentrated on a smaller area, enhancing sealing efficiency.

3. Application Scenarios:

High-Pressure or High-Temperature Systems: The stress concentration ensures a tighter seal, ideal for shipboard high-pressure oil, water, or steam pipelines.

Critical Systems with Strict Sealing Requirements: Prevents leakage in sensitive applications.

Heavy-Duty Pipelines: Standard choice where high sealing reliability is required.

Core Advantages of Marine-Grade Aluminum Flanges

Lightweight: Approximately one-third lighter than steel flanges, reducing ship weight and improving fuel efficiency.

Corrosion Resistance: Aluminum oxide surface resists seawater, salt spray, and chemical exposure, extending service life.

Easy Machining: Aluminum alloys are easy to weld, cut, and form, suitable for complex piping systems.

Cost-Effective: Lower raw material cost than stainless steel, with reduced maintenance expenses.

Easy Installation: Lighter weight simplifies handling and installation, increasing efficiency in shipyards and maintenance operations.

Chemical Resistance: Aluminum flanges are resistant to nitric acid, acetic acid, hydrogen peroxide, and other chemicals.

Non-Magnetic: Aluminum flanges are non-magnetic, ideal for applications requiring minimal magnetic interference.

Marine Applications

Fuel, Steam, and Compressed Gas Systems: Prefer raised face flanges for high-pressure sealing.

Drainage, Ventilation, and Low-Pressure Water Systems: Flat face flanges can simplify installation.

Application Examples

Cruise Ship Heating System

Flange Type: Raised Face Flange (ANSI Class 300)

Material: 6061-T6 Aluminum Alloy

Function: Connects steam pipelines, ensuring high-pressure sealing for the heating system.

Fishing Vessel Seawater Circulation System

Flange Type: Flat Face Flange (ANSI Class 150)

Material: 5052-H32 Aluminum Alloy

Function: Simplifies seawater pump installation while resisting saltwater corrosion.

Offshore Oil Platform

Flange Type: Raised Face Flange (ANSI Class 600)

Material: 5083-H321 Aluminum Alloy

Function: Connects high-pressure fuel pipelines, meeting extreme environmental requirements.

Original Source: https://www.marinealum.com/a/marine-grade-aluminum-flat-and-raised-face-flanges.html

Tag: Aluminum Flange Marine-Grade Aluminum Flange Pipe Fittings 5083 Aluminum Flange 6061 T6 Aluminum Flange Marine Aluminum Flange Aluminum Alloy Flange Marine Pipe Fittings Flat Face Flange Raised Face Flange