In modern shipbuilding and offshore engineering equipment, piping systems perform critical functions such as fuel transfer, cooling circulation, ballast water management, firefighting, and hydraulic control. As the core pressure-bearing, connecting, and sealing components of these systems, pipe fittings flange connections play a decisive role in overall system safety and service life. The performance of the selected material directly affects the reliability of the entire vessel.

Among various marine materials, 5086 marine aluminum alloy has become an important choice for aluminum pipe fittings and flange connections due to its excellent resistance to seawater corrosion, good weldability, and outstanding lightweight advantages.

Why Choose 5086 Marine Aluminum Alloy for Flanges?

5086 belongs to the 5xxx series marine aluminum alloys and contains a relatively high magnesium content (typically 3.5%-4.5%). This composition provides exceptional corrosion resistance, making it especially suitable for structural and piping components exposed to seawater, salt spray, and high-humidity environments over long periods.

Key Properties of 5086 Aluminum Alloy

1.Excellent Corrosion Resistance

In marine environments, 5086 alloy effectively resists salt spray, humidity, and chemical corrosion, ensuring long-term stability.

2.High Strength and Toughness

In the H32 temper, tensile strength can reach 315 MPa, with elongation at fracture exceeding 12%, making it suitable for high-pressure piping systems.

3.Good Weldability

Compatible with TIG and MIG welding, enabling strong and reliable joints for complex shipboard piping layouts.

4.Significant Lightweight Advantage

With a density of only about one-third that of steel, 5086 aluminum contributes substantially to vessel weight reduction, improved payload capacity, and enhanced fuel efficiency.

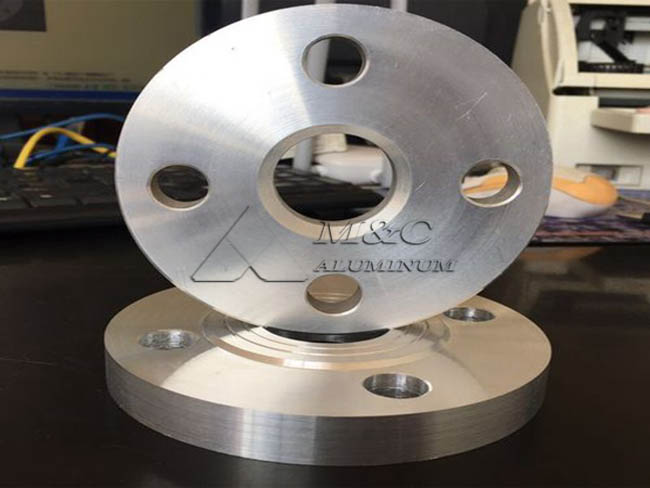

Core Functions of Marine Aluminum Flange Connections

Flange connections are far more than simple connectors. Within a piping system, they serve multiple critical functions:

Reliable Sealing

Maintain leak-free performance under complex operating conditions, including pressure fluctuations, temperature changes, and hull deformation.Load Bearing

Withstand internal pipeline pressure, external mechanical stress, and partial system weight.Ease of Maintenance

Provide detachable connection points for sectional inspection, cleaning, and replacement.Environmental Adaptability

Offer long-term resistance to marine salt spray, high humidity, and potential exposure to oils and chemicals.

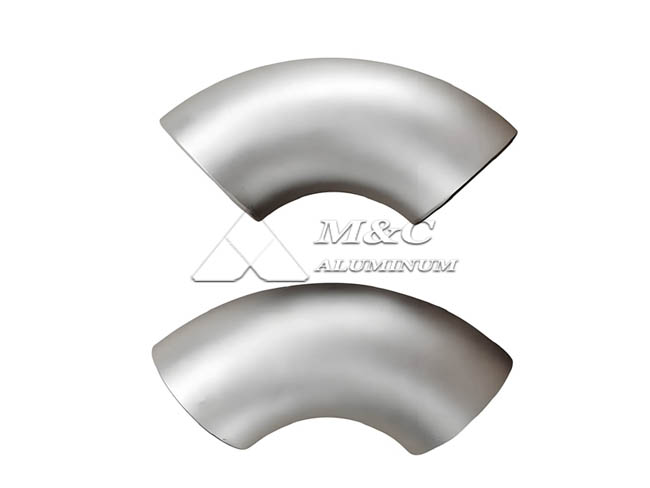

Structural Forms of 5086 Aluminum Flanges

The design of 5086 aluminum flanges must strictly comply with classification society standards (such as DNV-GL, ABS, LR, CCS, etc.). Dimensions, pressure ratings, and sealing face types (e.g., Raised Face (RF) and Flat Face (FF)) are standardized to ensure global interchangeability and safety.

Common types include:

Slip-On Flange

Weld Neck Flange

Blind Flange

Lap Joint Flange

Custom-shaped Flanges

Application Scenarios in Marine Engineering

Hull Piping Systems

Used in pump connections, fuel systems, and firefighting pipelines, where high pressure and corrosive environments are present.

Cooling Systems

Applied in engine coolant circulation systems, requiring low thermal expansion and high thermal conductivity.

Drainage and Ventilation Systems

Ensure tight sealing of drainage pipelines and prevent seawater ingress into the vessel.

Comparison with Traditional Materials

| Comparison Aspect | 5086 Aluminum Flanges | Traditional Steel Flanges |

| Weight | Extremely light, effectively reducing vessel center of gravity and overall weight | Heavy, increases structural load |

| Corrosion Resistance | Excellent, naturally resistant to seawater corrosion with low maintenance requirements | Relies on protective coatings; prone to pitting and rust |

| Maintenance Cost | Low, almost no replacement required over service life | Higher, requires regular inspection and potential replacement |

| Thermal / Electrical Conductivity | Good thermal and electrical conductivity | Relatively poor |

| Initial Cost | Higher material cost | Lower material cost |