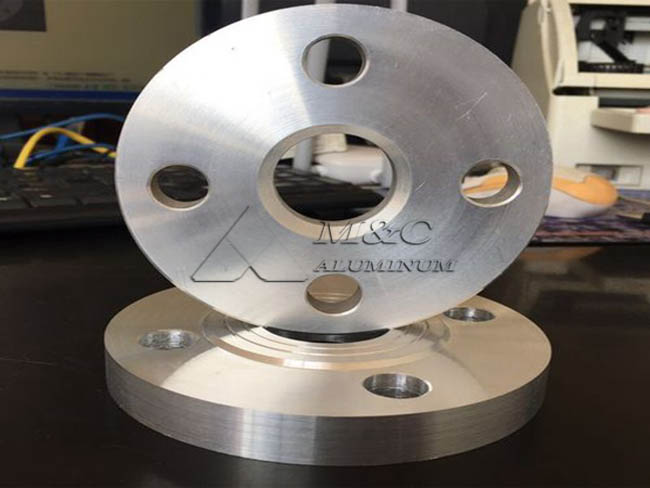

In modern industrial applications, flanges serve as essential components for connecting pipelines, valves, hull sections, and various structural parts. Their performance directly affects the safety, durability, and operational efficiency of a vessel. With advantages such as lightweight, fatigue resistance, and ease of processing, aluminum flanges have increasingly become a preferred choice in contemporary shipbuilding.

What Is an Aluminum Flange?

A flange is a disc-shaped component with bolt holes that is used in pairs. When tightened with bolts, it securely connects two sections of pipe, valves, or equipment, ensuring a sealed and leak-free joint. Flanges are typically made from metal materials such as steel or aluminum alloys.

Aluminum Flange Materials

1. 5xxx Series Aluminum Alloys (5052, 5083, etc.)

5xxx marine-grade aluminum alloys contain a high magnesium content (2.2–2.8%), which significantly enhances resistance to seawater corrosion and salt spray. This corrosion resistance is critical for deck piping, ballast systems, and exposed structural components.

2. 6xxx Series Aluminum Alloys (6061)

6xxx series marine-grade aluminum alloys contain both magnesium and silicon. They provide good corrosion resistance at moderate strength levels. Although their seawater resistance is slightly lower than 5083 in harsh marine environments, their main advantage lies in heat-treatable strengthening, which provides higher mechanical strength.

Manufacturing Processes of Aluminum Flanges

The main forming processes for flange blanks are forging and casting.

Forged Flanges

Forged flanges are produced by applying pressure to heated metal billets, causing plastic deformation and forming the required shape and dimensions. These flanges feature dense material structure, high strength, and superior mechanical properties, making them suitable for high-performance or critical locations.

Cast Flanges

Cast flanges are made by pouring molten metal into a mold cavity and allowing it to solidify and form. Casting is commonly used for flanges requiring complex shapes or large diameters.

Why Choose Aluminum Flanges?

1.Lightweight

Aluminum has only one-third the density of steel, significantly reducing the overall weight of the vessel and improving fuel efficiency.

2.Corrosion Resistance

Ships operate in environments characterized by saltwater, high humidity, and oxygen exposure. Aluminum flanges resist seawater corrosion and have a long service life.

3.Ease of Processing

Aluminum is easy to cut, machine, and weld, making it ideal for customized, complex piping systems.

4.Excellent Weldability

Both 5083 and 6061 alloys provide good weldability and are commonly welded using MIG or TIG processes.

5.Non-magnetic

Aluminum does not interfere with onboard electromagnetic equipment, making it suitable for specialized vessels.

6.Environmentally Friendly

Aluminum materials are 100% recyclable.

Common Flange Types and Application Scenarios

Welding Neck Flanges

Welding neck flanges feature a tapered neck that is butt-welded to the pipe. This design enables smooth stress transition and reduces turbulence and corrosion points. They are the preferred choice for high-pressure and high-reliability applications, such as marine main engine fuel lines and high-pressure hydraulic systems.

Slip-On Flanges with a Short Neck

These have a short neck and are fillet-welded on both the inner and outer sides. Stronger than flat slip-on flanges and easier to align than welding neck flanges, they are widely used in medium- and low-pressure ship piping systems.

Lap Joint Flanges

A lap joint flange consists of a flange ring and a stub end. The stub end is welded to the pipe, while the flange ring slips over it and is held in place with bolts. This structure is ideal for piping systems requiring frequent disassembly or for expensive pipe materials (such as copper-nickel alloys), as only the low-cost flange ring needs replacement.

Blind Flanges

Blind flanges have no center hole and are used to completely seal the end of a pipe or an equipment opening. They play a key role in isolation, sealing, and pressure testing during shipboard piping installation and maintenance.

Advantages Compared With Steel Flanges

| Comparison Dimension | Aluminum Flange | Steel Flange |

| Weight | Lightweight, reduces total vessel weight | Heavy, increases fuel consumption |

| Corrosion Resistance | Excellent seawater resistance, longer service life | Easily rusts, requires additional anti-corrosion treatment |

| Processing Cost | Lower cost, ideal for customization | Higher material and machining cost |

| Strength | Slightly lower strength, suitable for medium- and low-pressure systems | High strength, suitable for high-pressure systems |

Original Source: https://www.marinealum.com/a/material-characteristics-and-applications-of-marine-aluminum-flanges.html

Tag: 6061-T6 aluminum flange 5083 aluminum flange marine aluminum flange aluminum alloy flange pipeline fittings 5-series marine aluminum alloy 6-series marine aluminum alloy marine pipe fittings