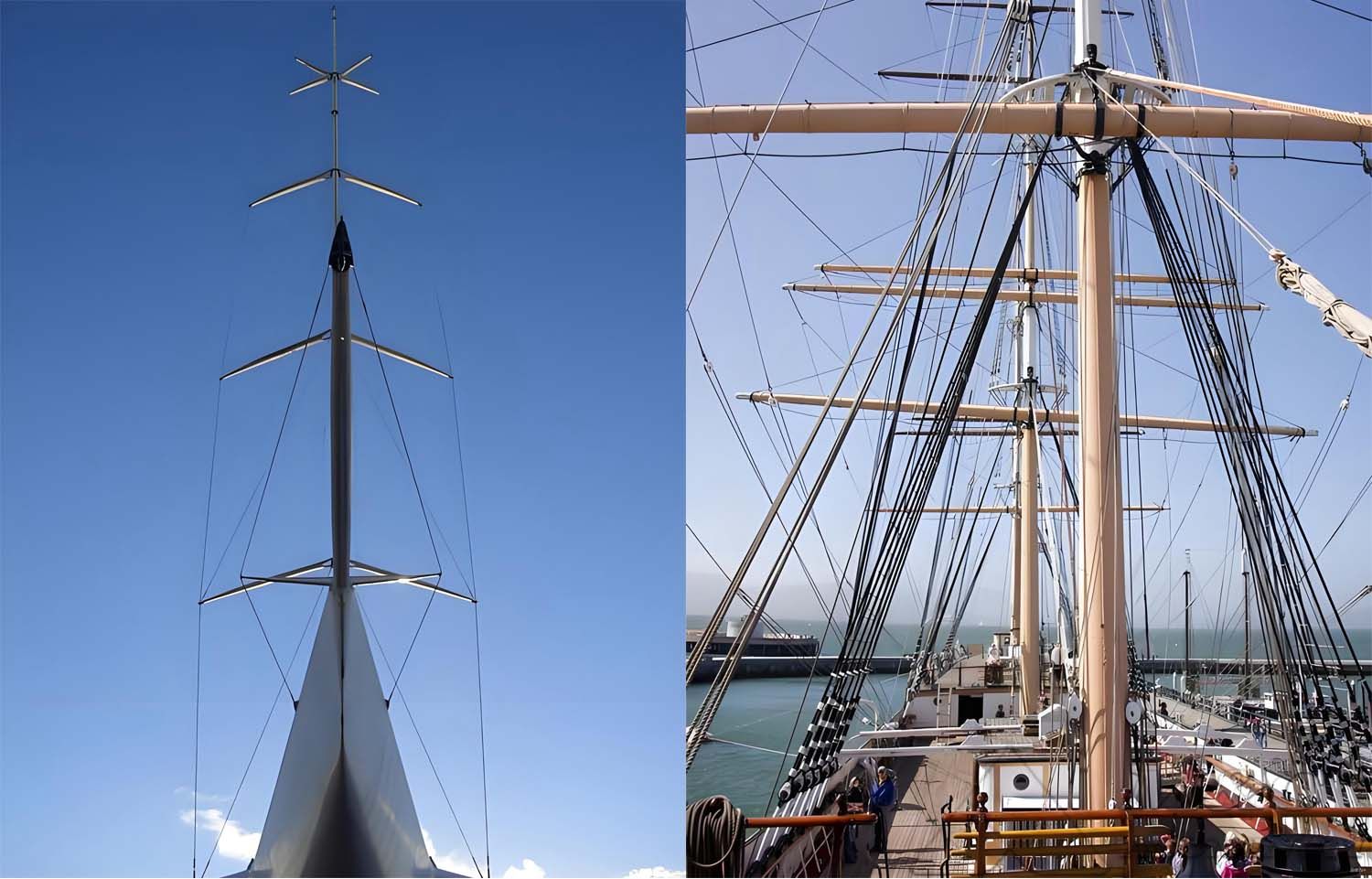

In ship design, especially for sailing yachts and high-performance vessels, the mast is a core structural element that harnesses wind force to propel the ship. A mast must not only withstand tremendous vertical compressive loads but also resist complex bending moments and shear forces caused by variable wind directions.

6082 marine aluminum alloy belongs to the 6xxx series (Al-Mg-Si) and is widely used in load-bearing structures and framework materials in the shipbuilding industry. Its performance is comparable to the US 6061 alloy.

Masts are typically made from 6082 seamless aluminum tubes, which effectively eliminate weld weaknesses, enhance overall mast strength and fatigue life, and ensure the stability and safety of tall masts.

Advantages of Seamless Aluminum Tube Technology

Choosing seamless tubes over conventional extruded or welded tubes provides irreplaceable structural benefits:

1. Seamless structure, uniform strength: Seamless tubes are manufactured via hot extrusion or piercing + cold drawing. Both the cross-section and longitudinal profile have no welds, eliminating stress concentration points and ensuring uniform microstructure.

2. Higher fatigue life: Masts constantly experience cyclic wind loads during sailing. Seamless tubes significantly outperform welded tubes in fatigue resistance, preventing fatigue fractures at stress-concentration points such as welds.

3. Precise wall thickness control: Seamless tubes have tighter wall thickness tolerances, ensuring the mast achieves the designed bending capacity without adding unnecessary weight.

Technical Specifications of 6082 Aluminum Tubes

| Alloy | 6082 |

| Temper | T6, T4, T6511 |

| Wall thickness | 2 mm - 40 mm |

| Outer diameter | 40 mm - 500 mm |

| Length | Up to 12 meters or more |

| Tensile strength | 90 - 340 MPa |

| Yield strength | 240 - 300 MPa |

| Elongation | 8% - 12% |

| Density | 2.70 g/cm³ |

| Elastic modulus | 70 GPa |

| Thermal conductivity | 160 - 180 W/m·K |

| MOQ | 1-3 tons |

Why Choose 6082 Seamless Aluminum Tubes for Ship Masts?

Weight reduction and efficiency:

Lightweight design reduces fuel consumption and improves speed and maneuverability, ideal for sailboats, patrol boats, and commercial vessels.Reliable equipment support:

High strength ensures masts remain stable under strong winds and rough seas, providing a stable platform for radar, antennas, and other precision equipment.Formability and weldability:

6082 seamless aluminum tubes are easy to cut, bend, and weld, supporting complex structural designs.Low maintenance cost:

Corrosion resistance reduces the need for anti-rust coatings, with a service life exceeding 20 years.Environmental adaptability:

Performs reliably in temperatures from -50°C to 80°C, even under extreme marine conditions.Eco-friendly and sustainable:

Aluminum is 100% recyclable, aligning with green shipbuilding principles.

Application Areas

6082 marine aluminum tubes excel in strength, weight, corrosion resistance, processing flexibility, and service life, making them the preferred material for modern yacht, sailboat, patrol boat, workboat, and offshore platform masts.

Original Source: https://www.marinealum.com/a/ship-masts-made-of-6082-seamless-aluminum-tubes.html

Tag: 6082 Marine Aluminum Alloy 6082 T6 Aluminum Tube 6082 Aluminum Tube Seamless Aluminum Tube Marine Aluminum Tube Marine Aluminum Profile 6082 Aluminum Extrusion Extruded Aluminum Profile Marine Aluminum Manufacturer