Marine aluminum plates are classified into wrought aluminum plates and cast aluminum plates based on their production process. Since shipbuilding imposes strict requirements on strength, corrosion resistance, and weldability, aluminum alloys used for marine applications must meet stringent standards. Among them, aluminum-magnesium alloys, aluminum-magnesium-silicon alloys, and aluminum-zinc-magnesium alloys are most common, with 5xxx series aluminum-magnesium alloys being the most widely used in shipbuilding.

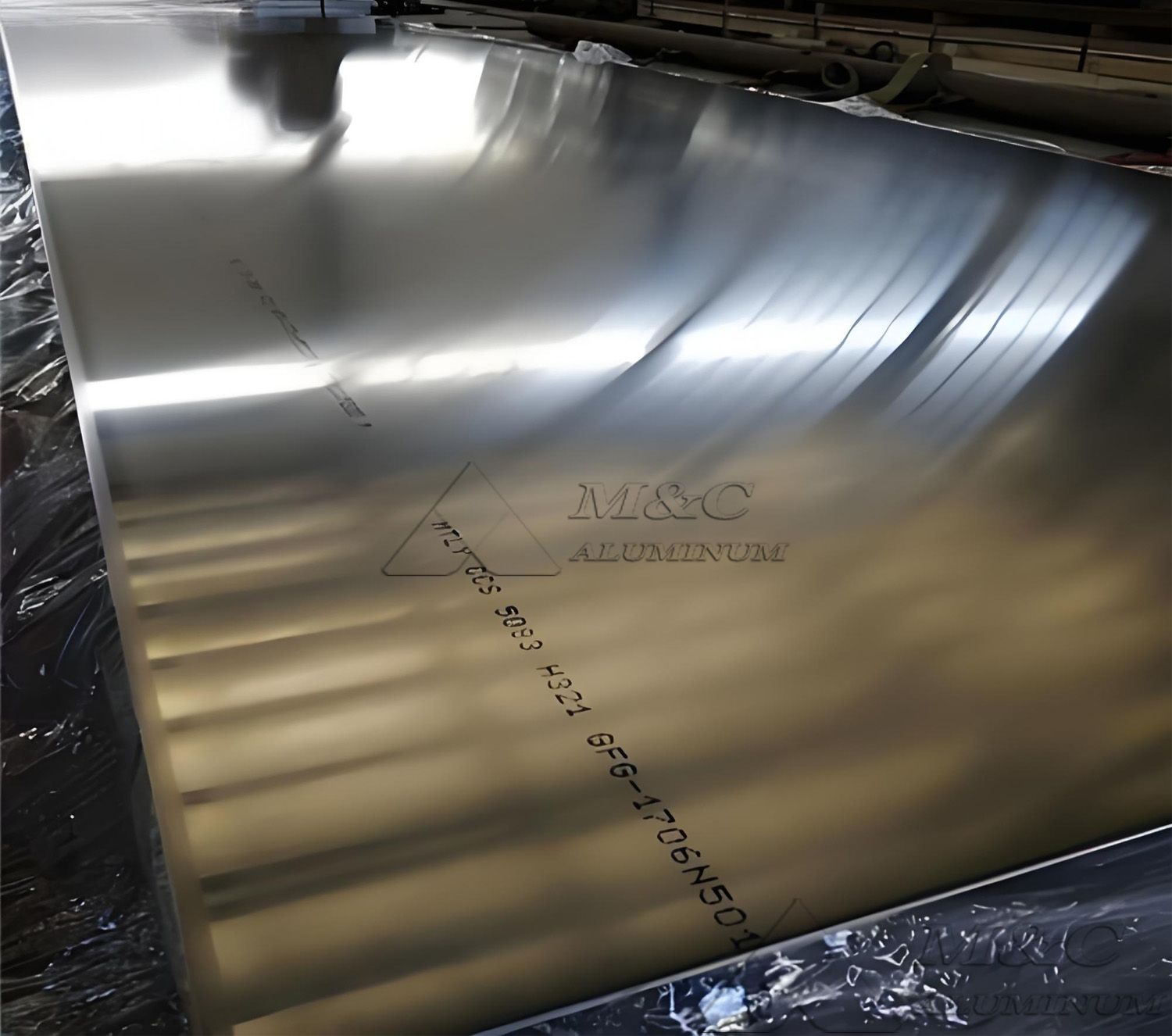

The most popular alloys include 5083, 5086, 5052, 5059, 5454, and 5456, where 5083 aluminum plate is the primary structural material for ship hulls due to its medium strength, excellent corrosion resistance, high fatigue strength, and good formability.

Common Tempers

The 5000 series alloys used in hull structures are in O and H states, while the 6000 series alloys are in T state.

Details:

H111: Annealed, then subjected to slight strain hardening (rolling or straightening)

H112: As-extruded or hot-rolled state, mechanical properties tested

H116: Cold-worked and low-temperature annealed, improved exfoliation corrosion resistance

H14: Half-hard, tensile strength between O and H18

H311: H31 with minor cold working

H32: Quarter-hard, cold worked, stabilized

H321: H32 with slight cold work for added stability

H323: Improved stress corrosion resistance based on H32

H34: Half-hard, stabilized

H343: Improved stress corrosion resistance based on H34

5 Series Marine Aluminum Product Information

| Alloys | 5052, 5083, 5086, 5454, 5754, etc. |

| Tempers | H116, H321, O, H112 |

| Thickness | 3 mm - 50 mm |

| Width | 1000 mm - 3000 mm |

| Length | 2000 mm - 12000 mm |

| Types | Plates, profiles, pipes, FSW panels, etc. |

| Surface finish | Mill finish, anodized, tread plate |

| Certifications | DNV, ABS, LR, CCS, BV |

| MOQ | 1–3 tons |

Chemical Composition, Properties, and Applications

| Category | Alloy | Temper | Chemical Composition (JIS Standard) | Features | Applications |

Ship Hull | 5052 | O, H14, H34 | Al: Balance; Si ≤0.25; Cu ≤0.10; Mg 2.2–2.8; Zn ≤0.10; Mn ≤0.10; Cr 0.15–0.35; Fe ≤0.40 | Medium strength, excellent corrosion resistance and formability, high fatigue strength | Upper structures, auxiliary components, small boat hulls |

| 5083 | O, H32 | Al: Balance; Si ≤0.40; Cu ≤0.10; Mg 4.0–4.9; Zn ≤0.25; Mn 0.40–1.0; Ti ≤0.15; Cr 0.05–0.25; Fe ≤0.40 | Highest strength among non-heat-treatable alloys, excellent weldability, corrosion resistance, low-temperature performance | Main ship hull structures | |

| 5086 | H32, H34 | Al: Balance; Si ≤0.40; Cu ≤0.10; Mg 3.5–4.5; Zn ≤0.25; Mn 0.20–0.7; Ti ≤0.15; Cr 0.05–0.25; Fe ≤0.50 | Similar to 5083, slightly lower strength, better extrudability | Hull structures (thin-wall, wide extrusions) | |

| 5052 | H32, H34 | Al: Balance; Si ≤0.25; Cu ≤0.10; Mg 2.4–3.0; Zn ≤0.25; Mn 0.50–1.0; Ti ≤0.20; Cr 0.05–0.20; Fe ≤0.40 | 22% stronger than 5052, good corrosion resistance and weldability | Hull structures, pressure vessels, pipelines | |

| O, H321 | Al: Balance; Si ≤0.50; Cu ≤0.10; Mg 4.7–5.5; Zn ≤0.30; Mn 0.30–0.9; Ti ≤0.15; Fe ≤0.50 | Similar to 5083 but higher strength, some stress corrosion sensitivity | Ship hulls, decks | ||

| 6061 | T4, T6 | Al: Balance; Si 0.4–0.8; Cu 0.15–0.40; Mg 0.8–1.2; Zn ≤0.25; Mn ≤0.15; Cr 0.04–0.35; Ti ≤0.15; Fe ≤0.70 | Heat-treatable alloy, high strength, but weld strength lower, not suitable for seawater contact | Superstructures, partitions, frames |

Advantages of 5 Series Marine Aluminum

1. Compared to steel, aluminum has a lower specific gravity, which reduces ship weight and increases speed, thereby reducing fuel consumption and conserving fuel.

2. Aluminum is inherently corrosion-resistant, effectively reducing painting and maintenance costs for ships and extending their service life to over 20 years.

3. Aluminum is easily cut, stamped, and cold-bent, perfectly adapting to streamlined ship designs. It can also be extruded into large, thin-walled profiles, reducing the number of welds and resulting in a more streamlined and lightweight hull structure.

4. Aluminum is easy to weld and can be efficiently joined to form a variety of complex hull structures.

5. Aluminum's low elastic modulus effectively absorbs impact stress, providing ships with greater impact resistance.

6. Aluminum waste is 100% recyclable, aligning with the concept of a circular economy and contributing to environmental protection.

7. Aluminum is not brittle at low temperatures, making it particularly suitable for ships operating in cold waters or for use in cryogenic equipment.

8. Aluminum is non-magnetic, which does not affect the proper functioning of a compass. Furthermore, all-aluminum boats can evade attacks from magnetic mines, making them particularly suitable for minesweepers.

9. Aluminum is non-flammable, making it safer in the event of a fire. It is also resistant to insects and does not deform due to drying.

Sizes and Types of Marine Aluminum Plates

HAOMEI Aluminum offers marine aluminum plate with thicknesses ranging from 3-50mm and widths from 1000-2650mm.

The thickness of the plate is determined by the hull structure, vessel specifications, and the intended location. To minimize hull weight, thin plates are generally preferred, but the potential for corrosion over time should also be considered. Typically, plates with a thickness of 3.0mm or greater and thicker than 30mm are used. To reduce welding, 2.0m wide aluminum plates are commonly used, while larger vessels use 2.5m wide plates. Lengths are typically 6m. Special specifications may also be specified based on shipyard contracts. For a non-slip effect, the deck utilizes patterned aluminum plates.

Marine aluminum alloys can be divided into the following categories according to product types:

Plates

Profiles

Aluminum pipes

Aluminum bars

Forgings

Castings

Applications of 5xxx Series Marine Aluminum Plates

Ship Hull Plating : 5083, 5086 plates for corrosion resistance and impact strength.

Decks and Bulkheads : 5456, 5754 alloys for structural strength and weldability.

Bottom Plates & Keel : Thick 5083 plates for load-bearing and impact resistance.

Piping and Fittings : 5052 alloy for pipelines, fuel systems, and onboard facilities.

Special Vessels : 5086, 5456 alloys for naval ships, patrol boats, and refrigerated vessels due to their high strength and low-temperature resistance.

Original Source: https://www.marinealum.com/a/5-series-marine-grade-aluminum-plates-for-ship-hulls-ccs-certified.html

Tag: CCS certified aluminum plate 5 series marine aluminum alloy 5 series marine aluminum plate 5 series marine grade aluminum plate 5083 marine aluminum plate 5086 marine aluminum plate 5052 marine aluminum plate 5059 marine aluminum plate 5454 marine