6082 aluminum alloy (belonging to the 6xxx series Al-Mg-Si system) is widely used in marine and structural applications due to its excellent balance of strength, workability, and corrosion resistance. After T6 artificial aging, 6082-T6 exhibits high yield and tensile strength, making it suitable for load-bearing components, extruded profiles, and connection members.

Difference Between 6082-T6 and 6061-T6 Marine Aluminum

Although the two alloys have similar chemical compositions, 6082 contains more manganese (Mn), which refines the grain structure and improves mechanical properties. As a result, 6082-T6 offers 10-18% higher yield strength and tensile strength than 6061-T6.

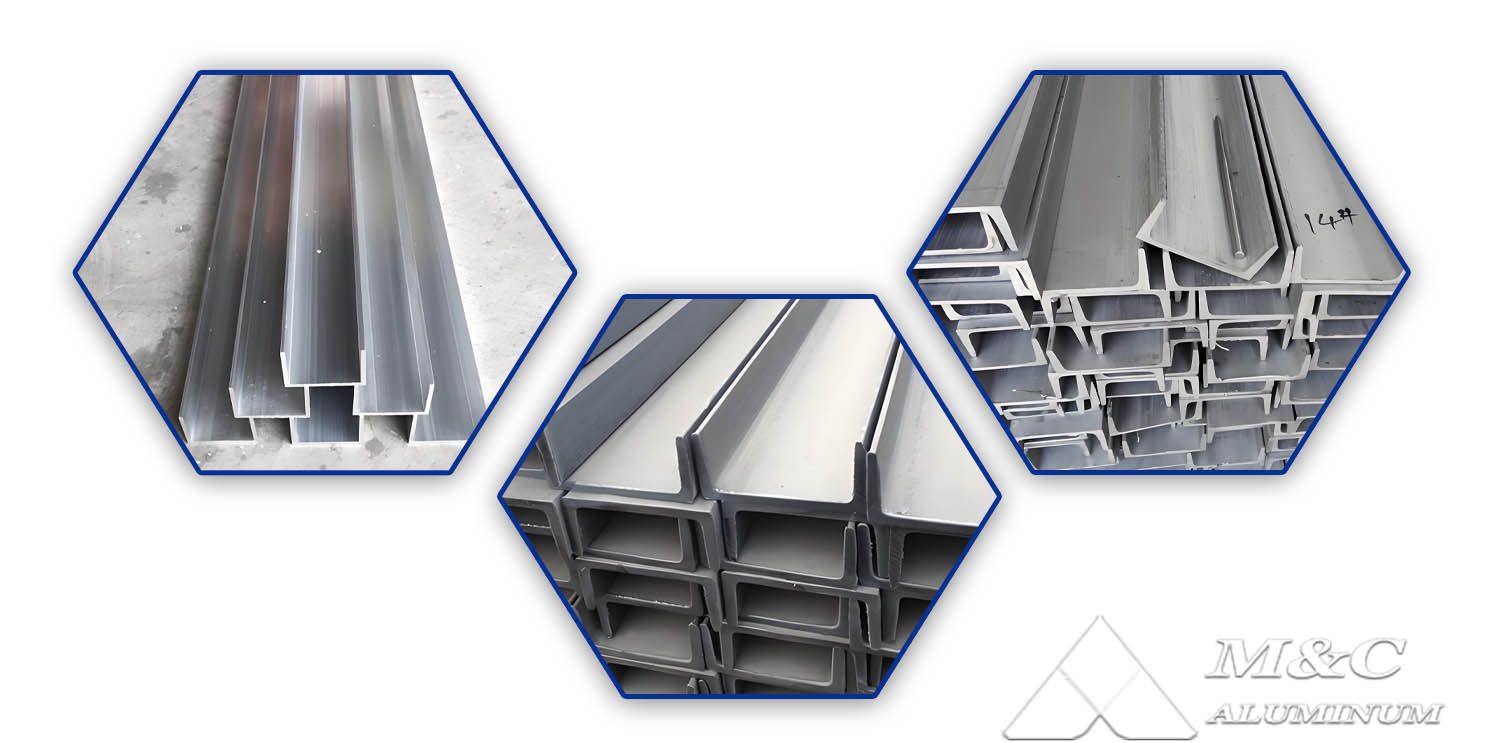

What Is a U-Channel Extruded Profile?

A U-channel (also known as aluminum trough or C-section) is one of the most common structural shapes in engineering. Using hot extrusion, a heated aluminum billet is forced through an extrusion die to obtain a consistent U-shaped cross-section.

When high-strength 6082-T6 alloy is extruded into a U-channel, it provides unique mechanical advantages:

1. Excellent Bending Resistance

The U-shaped geometry is naturally strong in resisting lateral loads, making it ideal for stiffeners and structural reinforcements.

2. Lightweight Structural Design

Compared with solid bars or thick-wall tubes, U-channels provide required stiffness with less material, reducing overall vessel weight and improving fuel efficiency or vessel speed.

3. Easy Installation

The open-slot design allows convenient welding, riveting, bolting, and panel-mounting connections.

Technical Specifications of Marine Aluminum U-Channels

| Alloy | 6082 |

| Temper | T6 |

| Cross-Section | U-channel (customizable by drawings) |

| Common Wall Thickness | 2.0 / 3.0 / 4.0 mm (customizable 1.5–10 mm) |

| Length | 6 m, 12 m or custom lengths |

| Surface Treatment | Anodizing, coating, powder coating |

| Extrusion Method | Hot extrusion |

| Certifications | CCS, BV, ABS, DNV, LR, etc. |

| MOQ | 1-3 tons |

Mechanical Properties (6082-T6)

| Ultimate Tensile Strength (UTS) | 260-310 MPa |

| Yield Strength (YS) | 200–260 MPa |

| Elongation | 8-12% |

| Density | ~2.70 g/cm³ |

| Brinell Hardness | 80-100 HB |

Performance Advantages of Marine-grade 6082-T6 U-Channel Extruded Aluminum Profiles

1. High Strength and Superior Load-Bearing Capability

6082-T6 is a high-Mg-Si alloy with notable tensile and yield strength. When used as U-channel structural components, it provides excellent rigidity and stability in highly stressed areas such as ship frames, deck reinforcements, and cabin structures.

2. Outstanding Corrosion Resistance for Marine Environments

6082 performs exceptionally well in seawater, salt-spray, and humid conditions. T6 temper further enhances overall stability and service life of marine components.

3. Excellent Weldability and Formability

Compared with 2xxx or 7xxx high-strength aluminum alloys, 6082 is more weldable with a lower tendency for hot cracking. U-channels can be easily extruded into complex shapes to meet various structural requirements.

4. Significant Lightweight Advantage

Aluminum's density is only one-third of steel, reducing ship weight while improving payload capacity, speed, and fuel efficiency - essential for modern lightweight vessel construction.

5. Good Fatigue Resistance

6082-T6 maintains strong performance under repeated cyclic loads, making it suitable for high-speed vessel structures, reinforcement rails, equipment brackets, and other components exposed to dynamic stress.

6. Extrusion Advantage: Fully Customizable Cross-Sections

U-channel dimensions can be designed according to shipyard requirements. Extruded profiles offer uniform mechanical properties, smooth surfaces, and consistent quality, ideal for mass-production shipbuilding.

7. Excellent Compatibility with Surface Treatments

6082-T6 can be anodized, painted, or powder-coated, offering additional corrosion protection and improved aesthetics for marine applications.

Typical Applications in Shipbuilding & Offshore Engineering

Floating Docks and Pontoon Bridges

6082-T6 U-channel profiles provide strong load-bearing support under variable wave forces.

Deck Supports and Railing Systems

Used as structural frames or mounting bases for deck safety systems.

Pipe & Cable Support Brackets

Corrosion resistance prevents damage to onboard pipelines and wiring systems.

Interior Cabin Structures

Lightweight U-channels are ideal for partition walls, furniture frames, and interior frameworks.

FAQ

Q1: Will 6082-T6 corrode quickly in seawater?

A: Bare aluminum may corrode in long-term seawater exposure, but 6082 offers excellent inherent corrosion resistance. With proper anodizing, coating, or electrical isolation, it meets the requirements of most marine and offshore installations. Avoid direct contact with steel or copper, or apply isolation materials.

Q2: How much load can a U-channel withstand?

A: Load capacity depends on section modulus, wall thickness, span length, and boundary conditions. Structural engineers should perform FEA or use engineering formulas with an appropriate safety factor.

Q3: How can strength be maintained after welding?

A: Welding softens the weld zone. For high-strength requirements, use mechanical fasteners, perform post-weld artificial aging, and conduct NDT inspections in critical areas.

Original Source: https://www.marinealum.com/a/marine-grade-6082-t6-aluminum-alloy-u-channel-extrusion-profile.html

Tag: 6082 T6 channel aluminum U-shaped aluminum extrusion aluminum U-channel aluminum alloy U-channel 6082-T6 marine aluminum 6061-T6 marine aluminum marine aluminum profiles marine extruded aluminum profiles 6082 aluminum extrusion