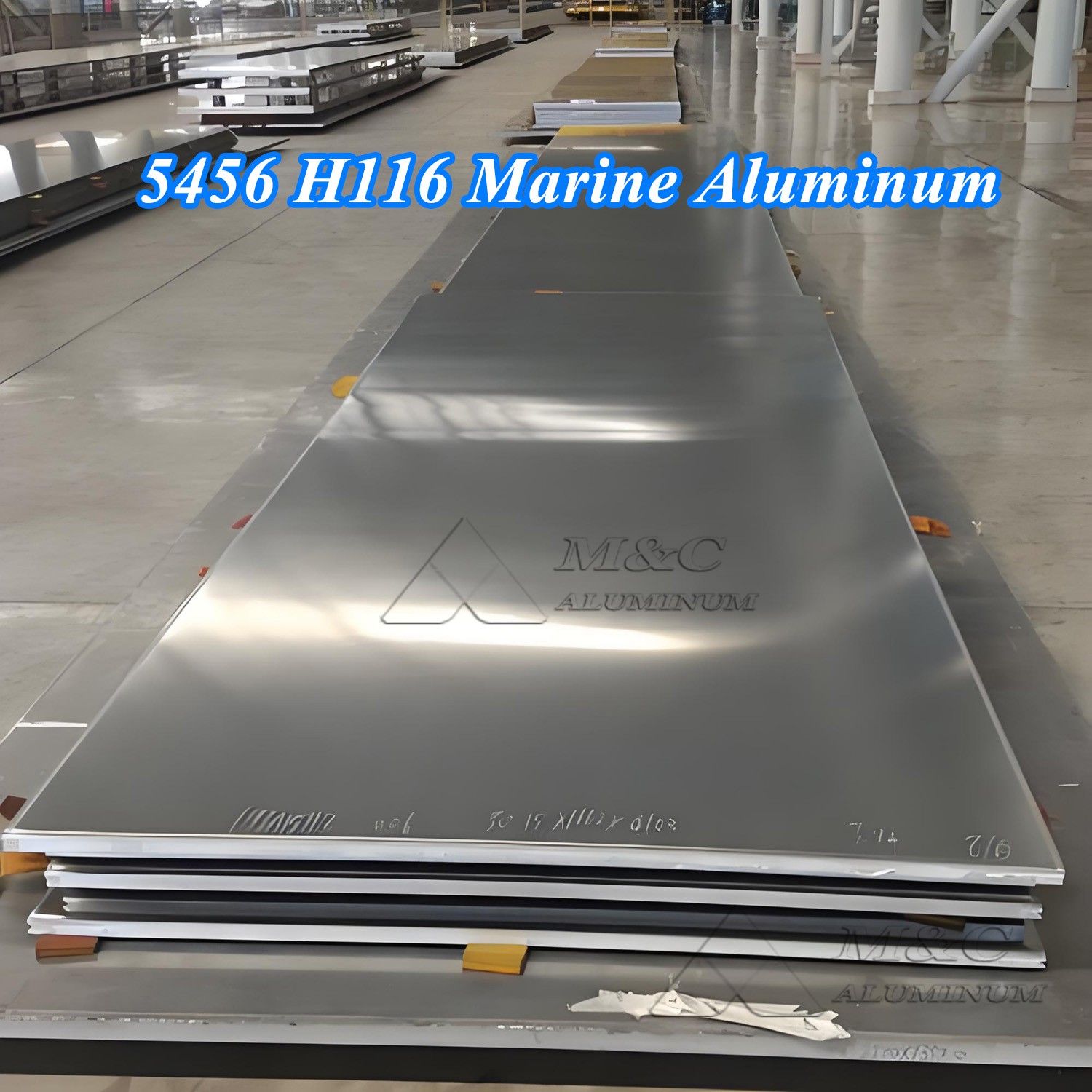

The 5xxx series aluminum-magnesium alloys are medium-strength, non-heat-treatable wrought alloys widely used in marine structures due to their light weight, weldability, and excellent corrosion resistance. Since the 1950s, the U.S. Navy has prioritized 5xxx magnesium-strengthened series (including 5083, 5086, and 5456) for naval applications.

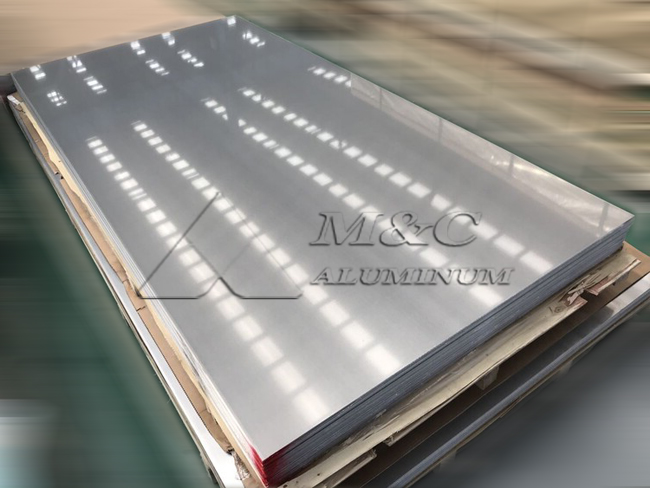

Among them, 5456-H116 aluminum-magnesium alloy is extensively used by the U.S. Navy to meet the demands of lightweight hull construction, high strength-to-weight ratio, corrosion resistance, and weldability. MC Aluminum supplies marine-grade aluminum plates used for yachts, hull keels, and shipbuilding projects-all certified by DNV GL, BV, LR, ABS, CCS, SGS, and other classification societies.

Key Advantages of 5456 Marine Aluminum Plate

1. Lightweight Design for Energy Efficiency

With a density of only 2.66g/cm³, 5456 aluminum significantly reduces vessel weight, enhancing speed and maneuverability.

2. Outstanding Seawater Corrosion Resistance

Containing 4.7–5.5% magnesium and a trace of manganese, 5456 alloy forms a dense oxide film in marine environments, providing superior protection against chloride ion erosion.

3. Higher Strength than 5052 and 5083 Alloys

Its tensile strength reaches 330–390 MPa, meeting the structural strength requirements of key load-bearing ship components.

4. Excellent Weldability

Even after high-temperature welding, it retains strong mechanical performance and structural stability, making it ideal for hull and structural welding applications.

Product Information

| Alloy | 5456 |

| Temper | H116 |

| Thickness | 3-50mm |

| Width | 1000–2650 mm |

| Length | 1000–16000 mm |

| Heat Treatment | Non-heat treatable, cold-work hardening |

| Welding | TIG/MIG and other welding methods |

| Certifications | ABS, DNV, BV, CCS available |

| Sample | Provided |

| Packaging | Standard export wooden box |

| MOQ | 1–3 tons |

Mechanical Properties of 5456 H116 Aluminum Plate

Yield Strength: ≥ 240 MPa

Tensile Strength: ≥ 352 MPa

Density: 2.66 g/cm³

Elongation (A50): ≥ 12%

Strategic Considerations Behind the U.S. Navy’s Use of 5456 H116

As a global maritime force, the U.S. Navy imposes strict material standards for naval vessels. 5456 H116 aluminum plate is used in frigates, amphibious assault ships, landing craft, and high-speed transport vessels due to several strategic advantages:

1. Durability for Long-Endurance Missions

Naval ships operate in complex marine environments year-round. The material’s superior corrosion resistance helps reduce maintenance, boosting operational continuity.

2. Compatible with Modular Ship Design

5456 plates offer excellent formability and flexibility, supporting various processing techniques such as laser cutting and waterjet cutting, ideal for modular shipbuilding.

3. Enhanced Tactical Maneuverability

Compared to steel hulls, aluminum alloys are significantly lighter, allowing faster acceleration, turning, and improved wartime responsiveness.

4. Weld Integrity Without Cracking

The H116 temper significantly reduces residual stress from welding, preventing microcracks and ensuring long service life and structural integrity.

MC Aluminum is a professional supplier of marine-grade aluminum plates, certified for yacht, fishing boat, and large vessel construction. As a large-scale marine aluminum supplier, MC Aluminum offers a wide range of aluminum grades including 6061, 5052, 5083, 5086, and 6063. We manufacture and supply extruded aluminum profiles at highly competitive factory-direct prices.

Original Source: https://www.marinealum.com/a/why-is-5456-h116-marine-aluminum-plate-favored-by-the-us-navy.html

Tag: 5456 marine aluminum 5456 marine-grade aluminum alloy 5456-H116 aluminum plate 5xxx marine aluminum alloy 5 series aluminum-magnesium alloy marine-grade aluminum plate marine aluminum supplier