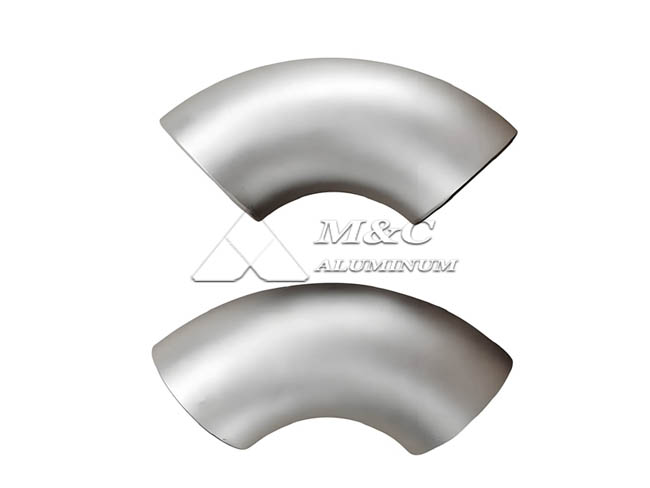

In marine piping systems, reliability and corrosion resistance are critical, making the choice of elbows especially important. Elbows made from 6063 aluminum alloy are widely used in ship cooling water systems, fuel systems, and HVAC ventilation systems, effectively meeting the complex piping layout requirements of modern vessel design. Compared with traditional steel elbows, 6063 aluminum alloy elbows significantly reduce pipeline weight, making ships lighter overall, thus improving fuel efficiency and sailing speed.

Why choose 6063 marine aluminum?

6063 aluminum alloy belongs to the Al-Mg-Si series of heat-treatable alloys. It offers excellent corrosion resistance, good weldability, and a high-quality surface finish. Compared with other marine aluminum alloys such as 5083 and 6082, 6063 is slightly weaker in strength, but thanks to its well-balanced properties, it remains an economical and reliable choice for many medium- and low-pressure piping systems onboard.

6063 aluminum elbows perform exceptionally in seawater desalination pipelines, ballast systems, and cooling water circulation lines, effectively resisting salt spray corrosion and extending pipeline service life.

Multi-angle design for complex ship piping

Marine aluminum alloy elbows are categorized by bending angle, with the most common types being:

45° elbow: Used for small-angle turns, often in tight spaces or where minor directional adjustments are needed.

90° elbow: The most widely used type, designed for vertical turns in piping.

180° elbow: Also known as a U-shaped elbow, it completely reverses the pipe direction and is commonly used in heat exchangers to extend pipe length and enhance heat transfer efficiency.

MC Aluminum produces elbows through precision extrusion and heat treatment processes, with customized dimensions and surface treatments (anodizing, coating, polishing) available to meet customer requirements.

Product Information - Marine Aluminum Alloy Elbows

| Alloy grade | 6063 |

| Temper | T5, T6 |

| Angles | 45° / 90° / 180° |

Diameter range | Φ20mm-Φ600mm (customizable) |

| Wall thickness | 2mm-20mm (customizable) |

| Surface treatment | Anodizing, brushing, coating, anti-corrosion coating |

| Samples | Available |

| MOQ | 1-3 tons |

Key Features of Marine Aluminum Alloy Elbows

1. Lightweight: Much lighter than traditional steel elbows, reducing overall ship weight and improving fuel efficiency.

2. Excellent corrosion resistance: Outstanding resistance in seawater and humid environments, greatly extending service life.

3. Good weldability and machinability: Easy to weld, cut, and install in shipyards, reducing construction time and cost.

4. Balanced strength and toughness: Medium strength with good ductility and toughness, ensuring resistance to vibration and impact during vessel operation.

5. Eco-friendly and recyclable: Aluminum can be recycled, supporting sustainable and green shipbuilding.

Applications of Marine-Grade Aluminum Elbows

Seawater desalination pipelines: Corrosion resistance ensures long-term stability of desalination systems.

Ship fuel and water supply/drainage systems: Lightweight and durable, ensuring efficiency and safety.

Deck and cabin ventilation pipelines: Promotes airflow and reduces energy consumption.

Offshore engineering equipment: Suitable for pipelines in drilling platforms and floating facilities.

Original Source: https://www.marinealum.com/a/45-90-180-degrees-marine-grade-aluminum-alloy-elbow-6063.html

Tag: 6063 aluminum elbow 6063 aluminum alloy elbow 45-degree aluminum elbow 90-degree aluminum elbow 180-degree aluminum elbow 6063 marine aluminum alloy pipeline fittings marine aluminum alloy elbow marine-grade aluminum elbow