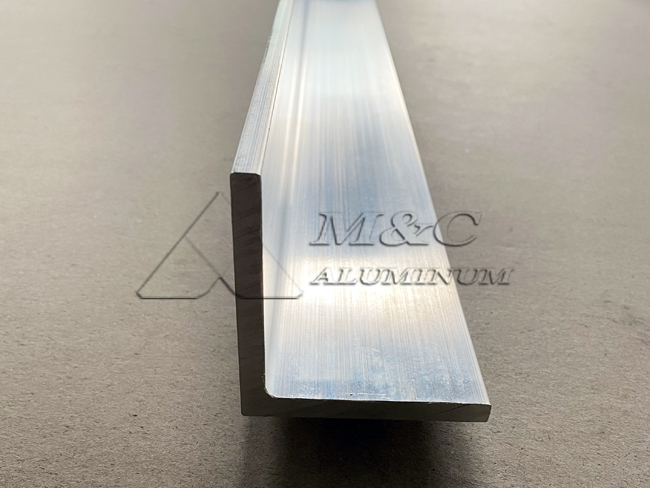

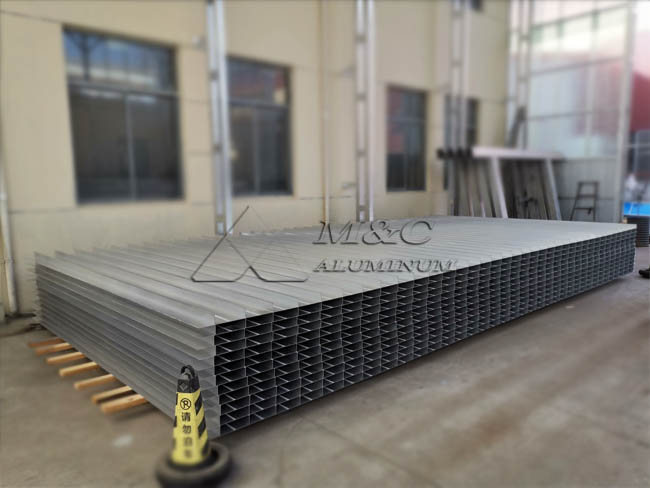

Marine-grade aluminum alloy rib plates are key components used in shipbuilding. Unlike steel, aluminum alloys offer the unique advantage of being extruded into profiles of virtually any shape, making them highly adaptable for stiffened plate structures. The geometry of stiffened aluminum plates plays a crucial role in the structural design and construction process of aluminum alloy ships.

Ribs are an essential part of the ship’s structure, usually arranged transversely between the bottom and deck, to support the hull, enhance structural strength, distribute loads, and improve resistance to deformation. Using aluminum alloy ribs allows shipbuilders to leverage its lightweight properties to reduce hull weight, thereby optimizing fuel efficiency and sailing performance. In addition, aluminum’s strong corrosion resistance minimizes seawater erosion, reduces maintenance costs, and extends the vessel's service life.

Common materials used in the production of marine-grade aluminum alloy ribs include 5083, 5086, and 6061. 5083 aluminum alloy is often chosen for marine ribs due to its high magnesium content, strong seawater corrosion resistance, and excellent strength, weldability, and low-temperature toughness. 6061 aluminum alloy, with its heat-treatable strengthening properties and excellent balance of strength and processability, is suitable for marine rib applications requiring high dimensional accuracy and overall performance.

Advantages of Marine-Grade Stiffened Aluminum Plates

1. High Geometric Precision

Stiffened plates are formed in a single extrusion process, with rib cross-sections and plate alignment controlled precisely by the die, replacing traditional manual welding. The resulting panels are closer to an ideal geometric plane, offering far greater global and local stability than conventionally welded plates.

2. Minimal Residual Stress, Better Stability

Studies and tests show that residual stress in extruded aluminum profiles is generally below 20 MPa, effectively negligible. This means stiffened plates experience virtually no additional stress under load, resulting in superior structural stability and safety.

3. Fewer Welds, Less Deformation

When ribbed plates are joined with longitudinal profiles, the number of welds is significantly reduced. This not only decreases welding workload but also minimizes deformation caused by welding, thereby lowering subsequent straightening and grinding costs.

4. Improved Economic Benefits in Shipbuilding

Stiffened aluminum plates enhance both mechanical and economic performance:

Higher strength and stability: Even load distribution with negligible residual stress.

Extended service life: Excellent corrosion resistance reduces maintenance frequency.

Lower manufacturing and maintenance costs: Less welding and correction work improves production efficiency.

Eco-friendly: Reduced welding means lower energy use and fewer emissions, supporting sustainable shipbuilding.

Typical CCS-Certified Aluminum Alloys for Rib Plates

5083-H116 / H321: Excellent seawater corrosion resistance, widely used in marine hull structures.

5456-H116: Higher strength than 5083, suitable for high-speed craft and naval vessels.

6061-T6 / 6082-T6: Outstanding strength, ideal for decks and high-load rib structures.

Applications of Marine Aluminum Rib Plates

(1) Ship Structures

a. Main ribs: Installed at every frame in transverse-frame hulls to support the inner bottom and bottom longitudinals.

b. Watertight / oil-tight ribs: Located beneath transverse bulkheads to ensure compartment sealing and withstand liquid pressure.

c. Special zones:

Engine and boiler foundations: Densely spaced ribs at every frame to carry concentrated loads.

Fore and aft peak tanks: Continuous ribs without interruption to enhance impact resistance.

(2) Offshore Engineering

a. LNG carriers: Aluminum alloy ribs are used in tank support structures, withstanding cryogenic temperatures (-163°C) while maintaining lightweight performance.

b. High-speed craft and patrol boats: 6061 or 5083 ribs are used to reduce hull weight and improve speed.

c. Offshore platforms: Applied in structures such as helicopter decks and floating bridges, offering corrosion resistance and easy maintenance.

Original Source: https://www.marinealum.com/a/ccs-certified-marine-grade-aluminum-alloy-ribs.html

Tag: ribbed plate aluminum alloy ribbed marine ribbed marine aluminum ribbed ship stiffened plate marine stiffened plate stiffened aluminum plate FSW panel marine FSW plate marine aluminum plate aluminum profile marine aluminum profile extruded alu