With the rapid development of marine transportation, offshore energy, and the yacht industry, the demand for lightweight, high-strength, and corrosion-resistant metallic materials is increasing significantly. Owing to its outstanding performance, 5083 marine aluminum plate has gradually replaced part of traditional steel, becoming a core material in shipbuilding.

Alloy Composition and Features

5083 aluminum alloy belongs to the typical Al–Mg–Mn series (5xxx series aluminum alloys). Its magnesium content generally ranges from 4.0% to 4.9%, with trace additions of manganese, chromium, and other elements. This composition makes it especially suitable for the marine environment.

One of its most critical attributes is corrosion resistance. For vessels operating long-term in seawater or exposed to the marine atmosphere, this is essential. 5083 forms a dense Al₂O₃ oxide film on the surface, effectively preventing further corrosion. In addition, its excellent weldability and formability allow manufacturers to design and construct complex ship structures.

Tempers of 5083 Marine Aluminum Plate

Common tempers include O, H111, H116, H321, and H32.

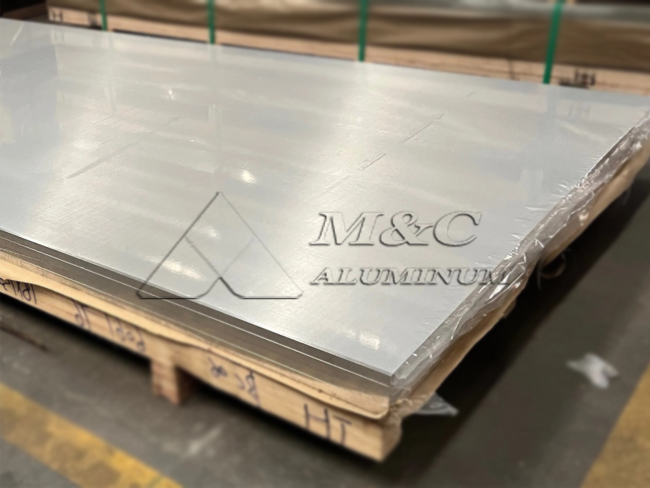

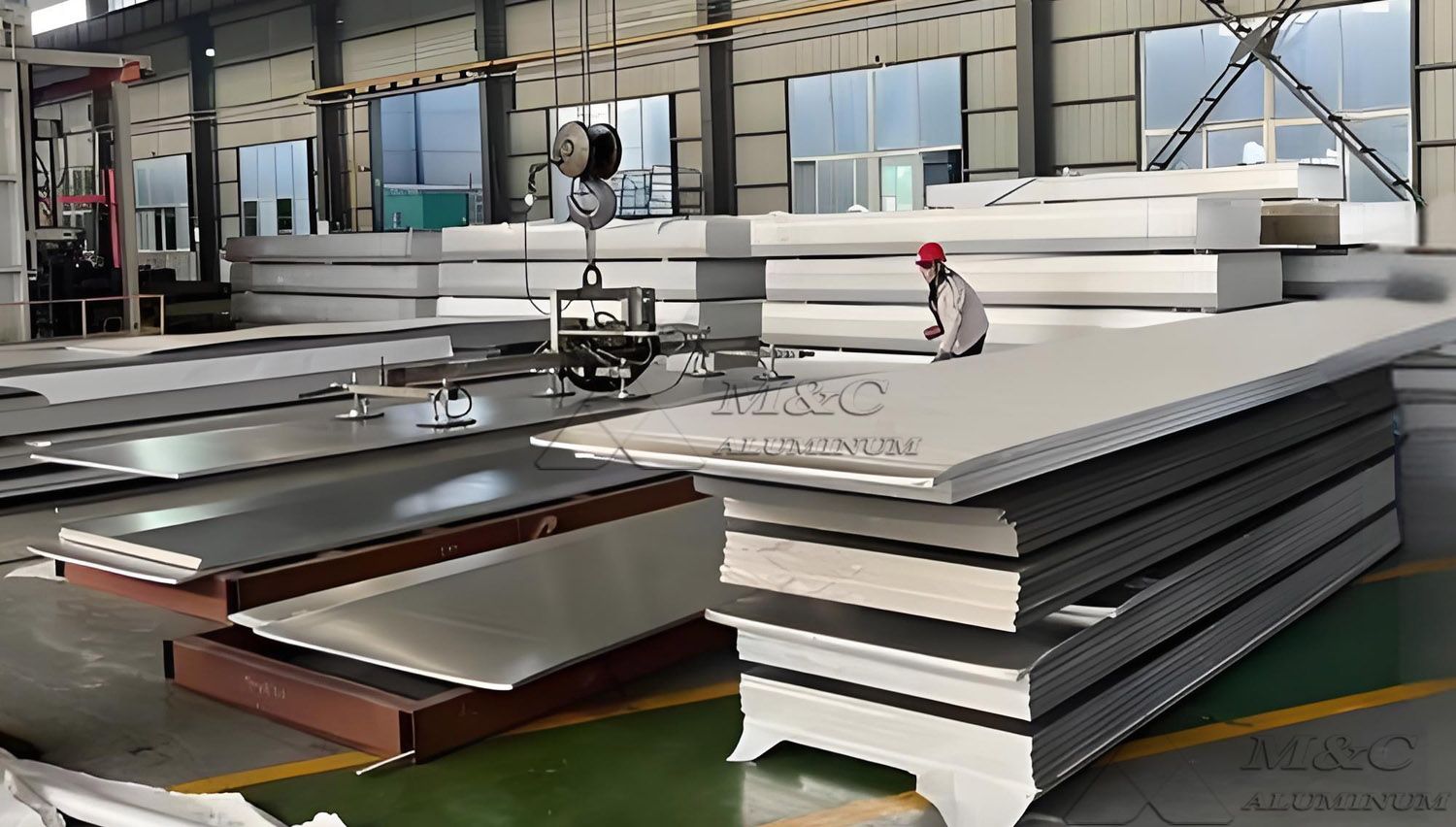

MC Aluminum provides thicknesses ranging from 3-50mm and widths from 1000-2650mm, customizable according to customer requirements. The products feature flat surfaces, free from black lines, indentations, or burrs at the edges.

H111: Slightly strain-hardened; lower strength but excellent ductility, ideal for formed parts.

H116: Specially processed for superior corrosion and exfoliation resistance; widely used for hull plating.

H321: Stabilized after strain hardening, offering enhanced resistance to intergranular corrosion; often used in offshore engineering and high-end hull structures.

Performance Advantages of 5083 Marine Aluminum Plate

1. Excellent corrosion resistance: Performs outstandingly in saltwater and marine atmospheres, making it the top choice for shipbuilding.

2. High strength: As a medium-high strength alloy, especially in annealed or H111 tempers, 5083 meets the structural strength requirements of vessels.

3. Superior weldability: 5083 is highly weldable. Using MIG or TIG welding processes, high-strength, crack-resistant welds can be achieved.

4. Good formability: In cold-worked states, it offers good plasticity, supporting bending, rolling, and stamping operations.

5. Outstanding low-temperature performance: Unlike many metals, 5083 maintains both strength and ductility at low temperatures, making it ideal for refrigerated vessels and LNG carriers.

Applications of 5083 Marine Aluminum Plate

Hull structures: Such as shell plating, keel, and ribs-requiring high strength and seawater corrosion resistance.

Decks and bulkheads: Its lightweight nature (density approx. 2.68g/cm³) helps lower the ship’s center of gravity, improving stability and payload.

Superstructures: Used in wheelhouses and living quarters, reducing weight while withstanding marine atmospheric corrosion.

Other marine parts: Such as fuel tanks, pipelines, and piping systems.

What is Mill-Finishing?

Mill-finishing refers to the final stage of aluminum plate production, where semi-finished plates are processed through precise rolling, stretching, trimming, and surface treatments to meet end-user requirements.

Advantages of Mill-Finished Processing

Improved surface finish: Effectively controls surface defects like indentations, scratches, or color differences, delivering near-mirror quality surfaces for welding and coating.

Smaller thickness tolerances: Achieves precision up to ±0.05mm, ensuring tight joints and uniform stress distribution in shipbuilding.

Refined microstructure: Fine-grained structure enhances mechanical properties and fatigue resistance, extending vessel service life.

Reduced residual stress: Advanced rolling control techniques release internal stresses, preventing warping and deformation during welding or forming.

Marine Classification Society Certifications

Mill-finished 5083 aluminum plates can be certified by DNV, CCS, LR, ABS, BV, and other major classification societies. Their surface quality, mechanical properties, and corrosion resistance meet or exceed international standards, ensuring long-term reliability in shipbuilding and offshore engineering applications.

Original Source: https://www.marinealum.com/a/mill-finished-marine-grade-5083-aluminum-plate.html

Tag: Marine-grade 5083 aluminum plate 5083 marine-grade aluminum plate 5083 aluminum plate 5083 marine aluminum plate 3-50mm marine aluminum plate 5083 H111 marine aluminum plate 5083 H116 marine aluminum plate 5083 H321 marine aluminum plate 5083 mari