In the fields of shipbuilding, offshore equipment, and marine engineering, the safety and durability of piping systems directly determine the operational reliability of a vessel. 5083 H116 / H321 marine aluminum flanges, with their outstanding resistance to seawater corrosion, stable mechanical performance, and extensive international application record, have become a preferred material solution for marine piping connection systems.

MC Aluminum manufactures 5083 aluminum flanges certified by major classification societies including DNV, ABS, LR, and CCS, meeting stringent requirements for long-term service in marine environments.

Why Choose 5083 Aluminum Alloy for Marine Flanges

5083 aluminum alloy belongs to the Al–Mg series of corrosion-resistant aluminum alloys. With a relatively high magnesium content and stable microstructure, it is one of the marine-grade alloys widely recognized by international classification societies. Compared with conventional aluminum alloys or carbon steel materials, 5083 offers clear advantages in seawater environments:

Excellent resistance to seawater and salt spray corrosion

Balanced combination of high strength and good toughness

Superior weldability with high post-weld strength retention

Low density, significantly reducing the weight of hulls and piping systems

Different Temper Conditions

H116 Temper:

Optimized for exceptional corrosion resistance, particularly effective in preventing exfoliation corrosion and intergranular corrosion. It is an ideal choice for ship hulls and marine structures.

H321 Temper:

Processed through controlled strain hardening and stabilization, offering enhanced structural stability and improved resistance to stress corrosion cracking.

Typical Mechanical and Physical Properties

| Parameter | 5083 H116 | 5083 H321 |

| Tensile Strength (MPa) | ≥315 | ≥295 |

| Yield Strength (MPa) | ≥170 | ≥165 |

| Elongation (%) | ≥12 | ≥10 |

| Electrical Resistivity (μΩ·cm) | 35-45 | 35-45 |

| Corrosion Rate (mm/year) | ≤0.02 (in seawater) | ≤0.02 (in seawater) |

Key Advantages of 5083 Marine Aluminum Flanges

1.Corrosion Resistance

Compared with carbon steel or stainless steel flanges, 5083 aluminum flanges can be used long-term in marine environments without complex anti-corrosion coatings, significantly reducing maintenance and replacement costs.

2.Lightweight Design

Aluminum flanges weigh approximately one-third of comparable steel flanges, effectively reducing pipeline system loads, improving fuel efficiency, and increasing payload utilization-particularly beneficial for high-speed vessels and specialized ships.

3.High Machining Accuracy

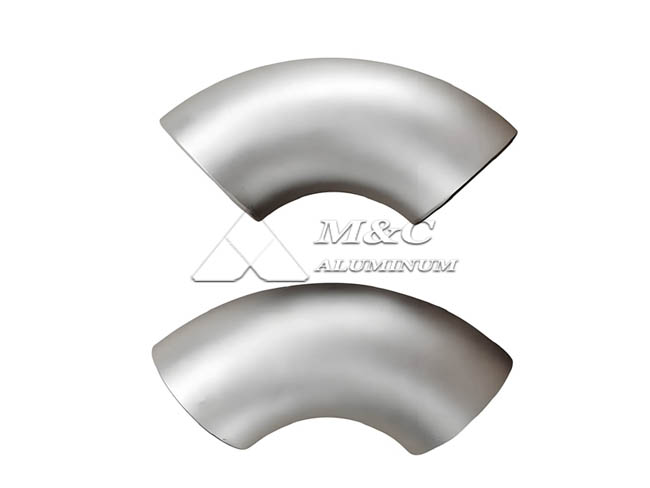

Using mature forging and CNC machining processes, the flanges achieve excellent sealing surface flatness and stable dimensional tolerances, ensuring reliable alignment with piping systems and minimizing installation risks on site.

4.Standardization and Customization

Products can be supplied in accordance with ANSI / ASME, DIN, EN, and JIS standards, while also supporting non-standard customization to meet specific vessel designs and project requirements.

Application Areas of 5083 Marine Aluminum Flanges

Shipbuilding: Essential for fuel lines, ballast systems, and cooling water circuits in high-speed ferries, yachts, and naval vessels.

Offshore Platforms: Used in seawater desalination units and firefighting systems, where weight reduction is critical for deck load management.

LNG Infrastructure: Takes advantage of the alloy's inherent ductility at low temperatures for liquefied natural gas handling systems.

Our Manufacturing Advantages

Strict Raw Material Control: Only certified and traceable 5083 magnesium ingots are used, ensuring magnesium content is maintained within the optimal range of 4.0%-4.9%.

Advanced Forging and Machining: Large-tonnage forging presses are employed to refine grain structure, followed by precision CNC machining to meet ANSI, JIS, or DIN standards.

Surface Integrity: Each flange undergoes careful deburring and surface finishing to ensure excellent gasket sealing performance at the flange interface.

Original Source: https://www.marinealum.com/a/5083-h116-h321-marine-aluminum-flange-performance.html

Tag: Marine aluminum flange marine-grade aluminum alloy flange ship pipeline flange fittings marine flange manufacturer 5083 aluminum flange DNV-certified aluminum flange pipe fittings aluminum alloy flange supplier