The 5754 aluminum alloy belongs to the Al-Mg series. It is known for its medium strength, excellent corrosion resistance, weldability, and easy forming properties. It is available in various tempers, including O, H22, H24, H32, H34, H38, H111, and H112. Among these, H111 and H112 tempers stand out in modern shipbuilding for their outstanding resistance to corrosion, moderate-to-high strength, and good weldability-making them ideal for ship structures and offshore facilities.

Why Choose MC Aluminum?

MC Aluminum strictly adheres to international classification society standards, including CCS, DNV, NK, ABS, BV, LR, and KR. These certifications ensure the products deliver superior corrosion resistance, excellent weldability, and high impact resistance for marine use.

Thickness Options for Marine Use

MC Aluminum offers 5754 marine aluminum plates in a wide thickness range, from thin sheets (0.2mm) to heavy plates (20–50mm). In shipbuilding, different structural parts require different thicknesses:

Hull Plating: Commonly 4–8mm in H112 temper to ensure structural strength.

Superstructure Walls: Use 2–3mm thin plates to reduce weight.

Reinforced Areas: Often require thick plates of 10mm or more.

Temper Selection: H111 & H112

H111 Temper: Ideal for parts that require further forming, such as curved hull panels. It is slightly strain-hardened and partially annealed, offering superior ductility and forming ability.

H112 Temper: Best suited for load-bearing structural components such as ribs, keels, and deck beams. It is hot worked and naturally cooled, retaining a degree of work hardening, which provides better dimensional stability and anti-deformation performance.

5754 Marine-Grade Aluminum Specifications

| Alloy | Temper | Thickness (mm) | Common Sizes |

| 5754 | O, H111 | 3.00–50.00 | 1250×2500mm, 1000×2000mm |

| H112 | 6.00–50.00 | ||

| H22, H32 | 3.00–6.00 |

Mechanical Properties of 5754 Aluminum in Shipbuilding

| Property | H111 | H112 |

| Tensile Strength | 190–240 MPa | 180–220 MPa |

| Yield Strength | ≥80 MPa | ≥70 MPa |

| Elongation | ≥12% | ≥15% |

| Density | 2.7 g/cm³ | 2.7 g/cm³ |

| Fatigue Strength | High | High |

| Electrical Conductivity | 35% IACS | 35% IACS |

Chemical Composition of 5754 Marine Aluminum (%)

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Other:Each | Other:Total | Al |

| 5754 | 0.4 | 0.4 | 0.1 | 0.5 | 2.6-3.60 | 0.3 | 0.2 | 0.15 | 0.05 | 0.15 | remainder |

Key Features of 5754 Marine Aluminum Plate

Excellent Corrosion Resistance

With a magnesium content of 2.6–3.6%, 5754 aluminum effectively resists seawater and humid environments. Commonly used in hulls and marine structures, it extends service life and reduces maintenance costs.Moderate Strength

Though not as strong as 7000 or 2000 series alloys, 5754 still provides adequate tensile and yield strength (especially in H112 temper) while maintaining excellent formability—ideal for medium and small vessel structures.Superior Weldability

Compatible with MIG/TIG welding, argon arc, and spot welding techniques. H111 and H112 states offer high crack resistance and maintain strength post-welding, minimizing thermal cracking or structural weakening.Lightweight Efficiency

With a density of 2.66 g/cm³ (about 1/3 of steel), it reduces ship weight, improves fuel efficiency, and lowers carbon emissions—supporting sustainability goals.Excellent Formability

Outstanding rolling, cutting, and cold-working capabilities make it suitable for complex ship structure designs, enhancing design flexibility and manufacturing efficiency.High Fatigue Strength

5754 alloy exhibits high resistance to fatigue stress, making it ideal for repeated stress conditions encountered during marine operations.

Typical Applications in H111 vs. H112 Tempers

(1) 5754-H111 Temper

Mildly work-hardened and partially annealed, offering a balance of strength and formability. Widely used in:

Hull shell plates

Deck surface layers

Cabin inner walls and bulkheads

Marine doors, window frames, and decorative parts

Curved surfaces requiring high formability

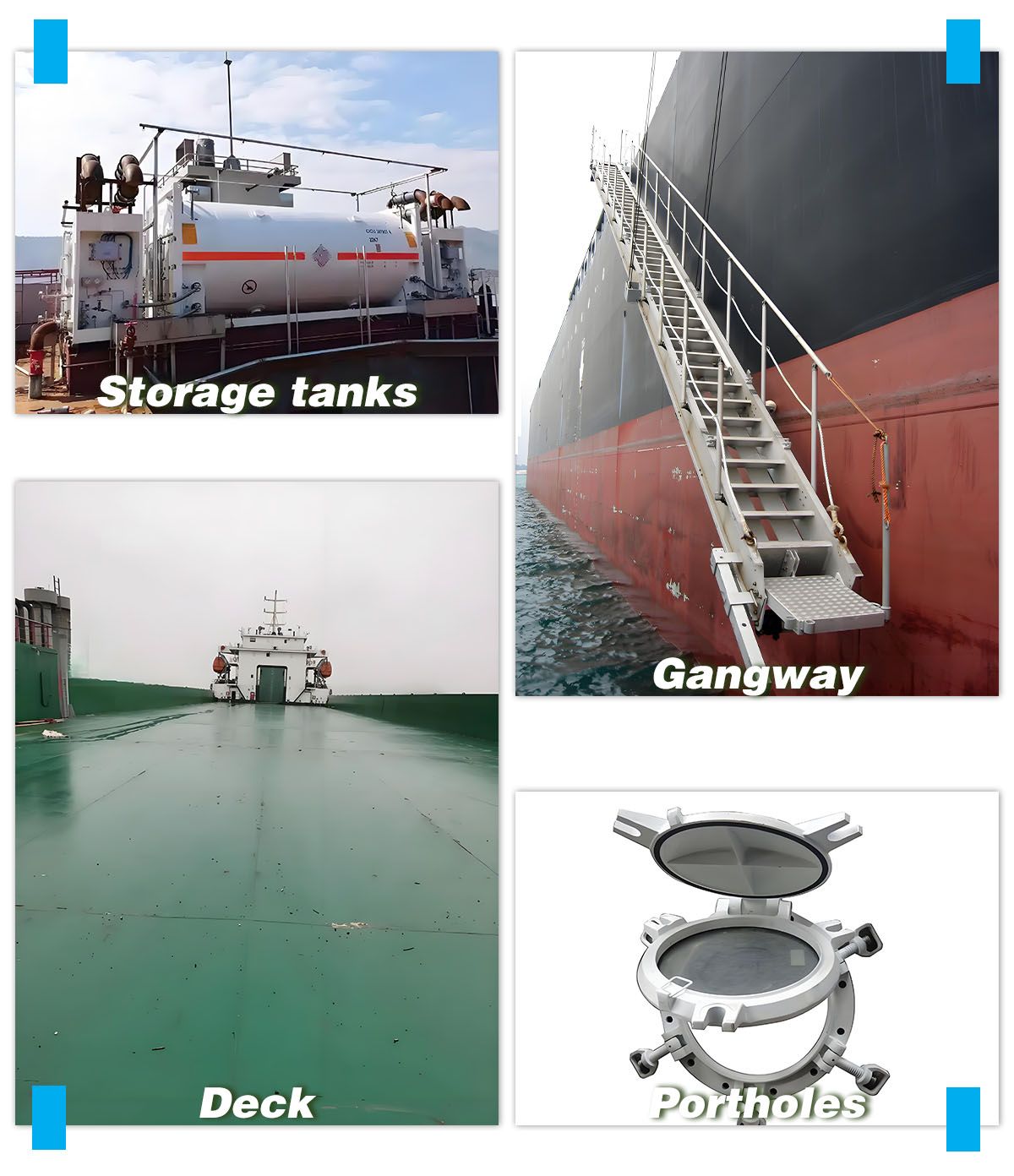

(2) 5754-H112 Temper

Naturally cooled after hot working without additional treatment. Suitable for:

Marine structural profiles and frameworks

Welded pressure vessels and storage tanks (e.g. ship cargo tanks)

Marine transport containers

Load-bearing structural components requiring enhanced strength

About MC Aluminum

As a leading manufacturer of marine-grade aluminum plates, MC Aluminum offers 5754 plates in thicknesses ranging from 0.15mm to 600mm and widths up to 2650mm, ideal for the production of large ship components. The surface finish is smooth and free from cracks, corrosion spots, or nitrate residues. Special patterns such as tread plates or embossed finishes are also available to meet anti-slip deck requirements.