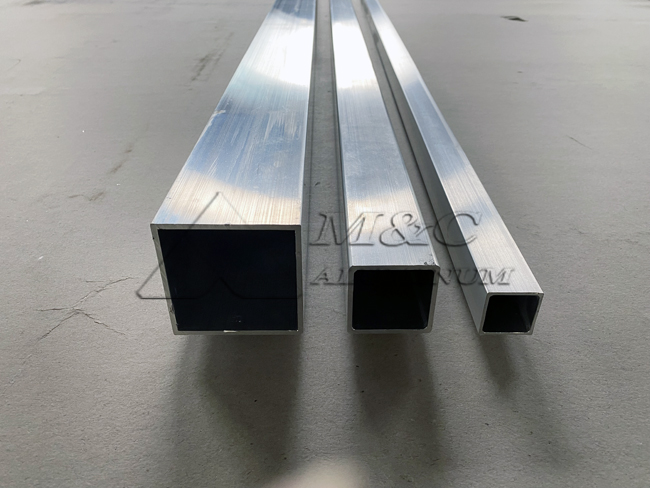

Marine aluminum tubes possess numerous excellent properties. Lightweight yet strong, they effectively reduce vessel weight and improve navigation efficiency. Additionally, their outstanding corrosion resistance allows them to withstand seawater erosion, extending the service life of marine structures. In shipbuilding, marine-grade aluminum tubes are essential materials that ensure both safety and performance, helping vessels navigate steadily across the open seas.

Manufactured from high-strength 5xxx and 6xxx series aluminum alloys, marine aluminum tubes are especially suited for long-term use in seawater environments. Common alloys include 5083, 6061, and 6082. For welding 5083 aluminum tubes, ER5356 welding wire is typically used, with heat input strictly controlled between 8–22kJ/cm. These products are certified by LR, ABS, CCS, and other classification societies, meeting the rigorous demands of marine environments.

5083 is the highest strength non-heat-treatable aluminum alloy and performs exceptionally well under extreme conditions. It offers excellent resistance to seawater and industrial chemical corrosion, though it is not recommended for use in environments above 65°C. Tempers such as H111, H112, H116, and H321 further enhance its strength and corrosion resistance.

5083 Aluminum Round Tube Chemical Composition

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Other:Each | Other:Total | Al |

| 5083 | 0.4 | 0.4 | 0.1 | 0.4-1.0 | 4.0-4.9 | 0.05-0.25 | 0.25 | 0.15 | 0.05 | 0.15 | remainder |

5083 Aluminum Round Tube Mechanical Properties

| Physical Property | Value |

| Density | 2.65 g/cm³ |

| Melting Point | 570°C |

| Thermal Expansion | 25 x 10⁻⁶ /K |

| Elastic Modulus | 72 GPa |

| Thermal Conductivity | 121 W/m·K |

| Electrical Resistivity | 0.058 x 10⁻⁶ Ω·m |

Key Features of 5083 Marine Aluminum Tube

1.Corrosion Resistance

In marine environments, 5083 aluminum forms a dense oxide layer that effectively blocks chloride ion penetration. Its corrosion resistance is superior to that of standard carbon steel.

2.Low-Temperature Performance

At ultra-low temperatures (as low as -196°C in liquid nitrogen), it maintains excellent impact toughness at 25 J/cm²—ideal for LNG carriers and other cryogenic applications.

3.Excellent Weldability and Workability

Weld joints achieve 95% efficiency, and weld strength reaches up to 90% of the base material. Cold bending radius can be as small as 1.5 times the wall thickness. Processing energy consumption is reduced by 60%.

4.Lightweight Advantage

With a density of only 2.66 g/cm³, the use of 5083 aluminum tubes can reduce overall ship weight by up to 45%, improving fuel efficiency by approximately 22%.

Application Scenarios

Piping Systems

Used for seawater transport pipes, fuel lines, and lubrication conduits. Under 2.5MPa working pressure, wall thickness reduction over 5 years is just 0.08mm—offering better longevity than stainless steel.Hull Structures

12mm-thick plates in H116 temper are used for main hull construction. Weld joints deliver tensile strength over 290MPa and elongation above 10%, meeting DNV-GL classification requirements.Special Components

Includes rudder shafts, masts, deck supports, and movable bridge structures. An 85-meter-span bridge made from 5083 has a first natural frequency of 1.2Hz, reducing resonance risk by 73%.Cabins and Decks

Helicopter decks experience deformation of less than 3.2mm under sea state level 9. Corrugated aluminum plates used in living quarters reduce noise by up to 55dB and lower vibration acceleration by 42% compared to steel.