Among the many marine-grade aluminum alloys, 5083 aluminum plate is one of the most widely used due to its excellent corrosion resistance, high strength, and outstanding weldability. Especially in the H111, H112, and H116 tempers, it is extensively applied in structural components across diverse marine environments.

MC Aluminum manufactures 5083 marine aluminum plates in a wide range of thicknesses from 3mm to 50mm, with extra-wide widths up to 2650mm and lengths up to 16,000mm. Our products are certified by CCS, ABS, LR, and other leading classification societies to meet rigorous global standards.

Overview of 5083 Marine Grade Aluminum Plate

5083 is an Al-Mg series aluminum alloy, with magnesium as the primary alloying element. It features moderate to high strength, excellent weldability, and superior resistance to seawater corrosion. This makes it an ideal material for long-term service in marine climates, humid environments, and salt spray conditions.

Common Marine Tempers of 5083 Aluminum:H111,H112,H116

Characteristics of 5083 Tempers

This temper undergoes light strain hardening and partial annealing. It offers an excellent balance between formability and strength, ideal for deep drawing and bending. Commonly used in hull plates, bulkheads, and decks, where high forming performance is essential.

Typically used after hot forming, H112 plates are not cold worked, but stabilized by heat treatment to ensure mechanical stability. It has higher strength than H111, but slightly reduced formability. Suitable for components that demand greater structural strength, such as keel sections, reinforcements, and large-scale assemblies.

The most popular marine-grade temper of 5083, especially for external hull plating. It is processed through controlled cold work and precipitation control to ensure high strength and excellent exfoliation corrosion resistance-a form of corrosion common in high-stress marine applications. The optimized cold work ratio (7-12%) makes H116 the best choice for outer hulls, superstructures, and submarine surfaces, ensuring durability and safety in long-term marine service.

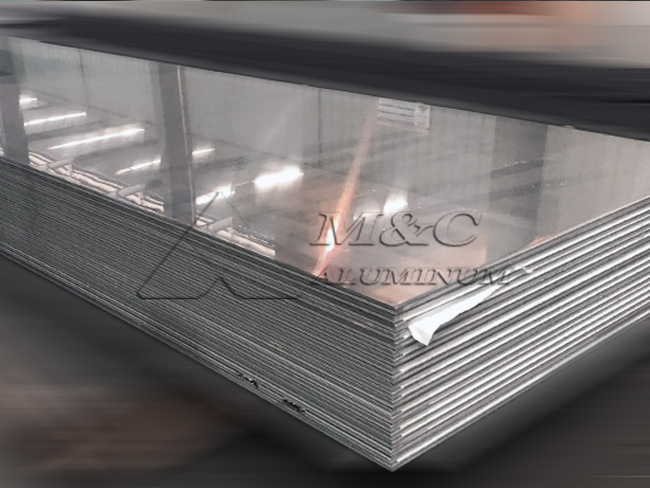

Product Specifications

| Alloy | 5083 |

| Tempers | H111, H112, H116, etc. |

| Thickness | 3mm - 50mm |

| Width | 1000mm - 2650mm |

| Length | 1000mm - 16,000mm |

Why Choose 5083 Aluminum in Shipbuilding & Marine Engineering?

1.Corrosion Resistance

5083 aluminum forms a dense oxide layer that, along with its alloying elements, provides superior resistance to seawater and salt fog corrosion-critical for marine applications.

2.High Strength & Lightweight

With a density of only 2.7g/cm³ (33% lighter than steel), 5083-H116 offers tensile strength of 270-320 MPa and yield strength of 130-170 MPa-ideal for both load-bearing and weight-reduction in ship structures.

3.Excellent Weldability

5083 aluminum can be reliably welded using TIG, MIG, or gas-shielded arc welding, without the risk of cracks or porosity. Its weld-friendly nature makes it perfect for large marine and bridge assemblies.

4.Eco-Friendly & Recyclable

Fully recyclable with low energy consumption during remanufacture. Complies with the EU 2025 directive requiring ≥90% recyclability of shipbuilding materials-supporting global green manufacturing.

5.Non-Magnetic Properties

Crucial for mine countermeasure vessels or research ships, where magnetic interference must be avoided.

Applications of 5083 Marine Grade Aluminum

Hull plates & keel structures (e.g. fishing boats, patrol vessels, yachts)

Offshore platform decks

Ferries, speedboats, water buses

Chemical storage tanks, liquid transport tankers

Cold storage container liners

Port equipment, aluminum floating bridges

Naval ship armor plates & superstructures

Why Choose Our Marine Grade Aluminum?

1. Complete Range of Tempers:

Available in H111, H112, H116, and other custom tempers from 1.0mm to 200mm thickness.

2. Tailored Solutions:

Custom cutting, fixed-length processing, surface finishes (e.g., sandblasting, brushing), all tailored to shipyard or project drawings.

3. Global Certifications:

Certified by DNV-GL, ABS, CCS, and other international classification societies.

4. End-to-End Service:

We provide technical support, fast delivery, and export-grade packaging for global clients.

MC Aluminum is a specialized manufacturer of marine-grade aluminum. In addition to 5083, we supply 5052, 5086, 5454, and 5456 alloys for ship structures, tanks, pipelines, hulls, and decks. With full temper options, custom sizing, and massive production capacity, we serve customers worldwide with short lead times and sample support. For any inquiries, please feel free to contact us!