In modern marine engineering, the exhaust system is a critical component that ensures safe and efficient engine operation. Traditionally, exhaust flanges were made from cast iron or stainless steel. However, with the increasing demand for vessel lightweighting and high performance, 6061-T6 aluminum alloy flanges are becoming an ideal choice for high-performance boats, commercial ships, and yacht exhaust systems.

6061 aluminum alloy belongs to the Al-Mg-Si series heat-treatable alloys. After T6 treatment (solution heat treatment + artificial aging), its strength and hardness are significantly improved, making it one of the most balanced and widely used aluminum alloys.

6061 aluminum offers good natural corrosion resistance. In marine atmospheres and freshwater environments, it forms a dense aluminum oxide layer. Although its corrosion resistance is not as strong as 5xxx-series Mg-rich alloys (such as 5052 or 5083), it performs excellently in mid- and high-temperature dry sections of exhaust systems, and with proper surface protection, it fully meets marine requirements. Its high strength-to-weight ratio is especially valuable-using aluminum flanges significantly reduces the weight of the exhaust system and the overall vessel, directly improving load capacity and reducing fuel consumption.

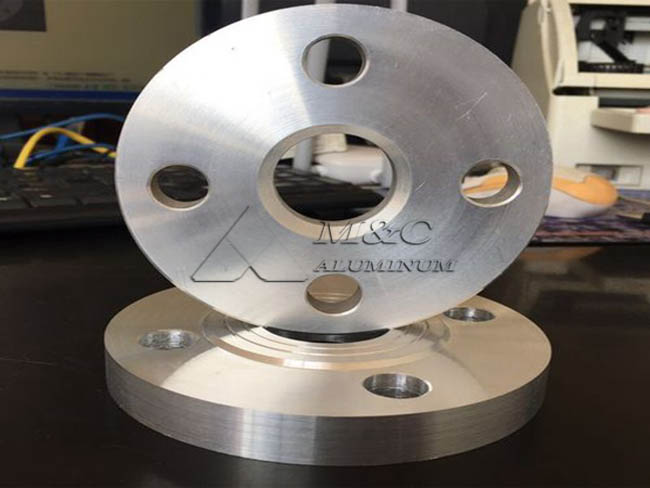

Common Types of Aluminum Flanges

Typical flange configurations include:

Welding Neck Flange

Slip-on Flange

Blind Flange

Threaded Flange

Lap Joint Flange

Physical Properties of 6061-T6 Aluminum Flanges (Typical Values)

| Density | 2.70 g/cm³ |

| Melting Point | 582-652°C |

| Elastic Modulus | 69 GPa |

| Thermal Conductivity | 151-170 W/m·K |

| Electrical Conductivity | 40-44% IACS |

Mechanical Properties

| Ultimate Tensile Strength (UTS) | 290–320 MPa |

| Yield Strength (YS) | ≥240 MPa |

| Elongation | 8-12% |

| Hardness | ~95 HB |

Advantages of 6061-T6 Aluminum Flanges in Marine Exhaust Systems

1. Significant Weight Reduction Improves Vessel Efficiency

6061-T6 aluminum has only one-third the density of steel. Using aluminum flanges reduces pipeline weight, lowers vessel fuel consumption, and improves the exhaust system’s dynamic response.

2. Strong Corrosion Resistance for Marine Environments

Mg and Si in the alloy form a stable oxide film. In salt-spray environments, aluminum flanges perform better than carbon steel flanges and require lower maintenance costs.

3. Excellent Thermal Stability in High-Temperature Conditions

The high thermal conductivity of 6061 aluminum helps dissipate heat quickly, reducing thermal fatigue and enhancing the reliability of the exhaust system.

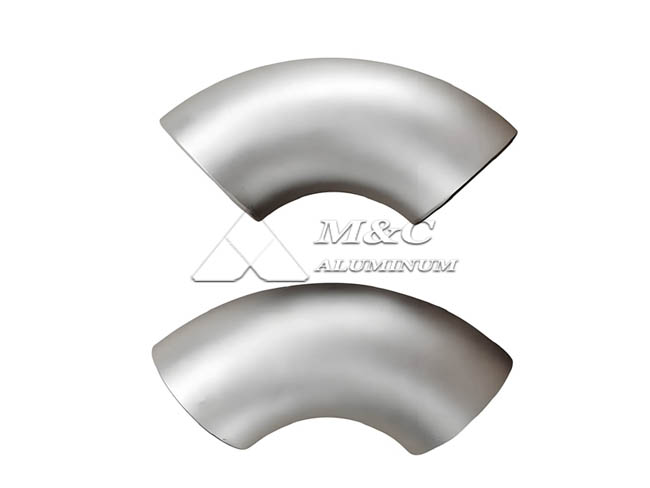

4. Superior Machinability and Weldability

6061-T6 can be CNC-machined, turned, drilled, and tapped easily. It supports TIG/MIG welding, making it suitable for onboard fabrication and repair.

5. High Strength and Reliable Sealing Performance

With high yield strength in T6 temper, the flange maintains sealing integrity under vibration, impact loads, and high-temperature exhaust pressure.

Corrosion Protection Strategies for Marine Exhaust Flanges

6061-T6 aluminum flanges inherently possess good corrosion resistance. However, marine environments-combined with temperature cycling and internal exhaust gas chemistry-pose several corrosion challenges. The main corrosion risks include:

Galvanic corrosion

Crevice corrosion

High-temperature oxidation and sulfidation

To ensure long service life, the following protection strategies are recommended:

1. Cathodic Protection

For exhaust sections that may contact seawater (e.g., water-cooled exhaust zones), sacrificial aluminum anodes can be used for protection.

2. High-Performance Protective Coatings

Coatings are the most direct and effective protective method.

Use high-temperature, chemically resistant anti-corrosion coatings to protect the aluminum flange surface.

3.Surface Treatment Technology: Micro-arc oxidation (MAO) is an advanced surface ceramicization technology that can grow a high-hardness, high-bonding-strength, wear-resistant, and corrosion-resistant ceramic oxide film in situ on the aluminum alloy surface, greatly extending the service life of flanges in harsh environments.

4.Electrical Insulation Design: At the connection between the flange and dissimilar metals, using insulating gaskets, sleeves, or applying an insulating coating to the fasteners physically breaks the galvanic corrosion circuit, which is the fundamental method for controlling galvanic corrosion.