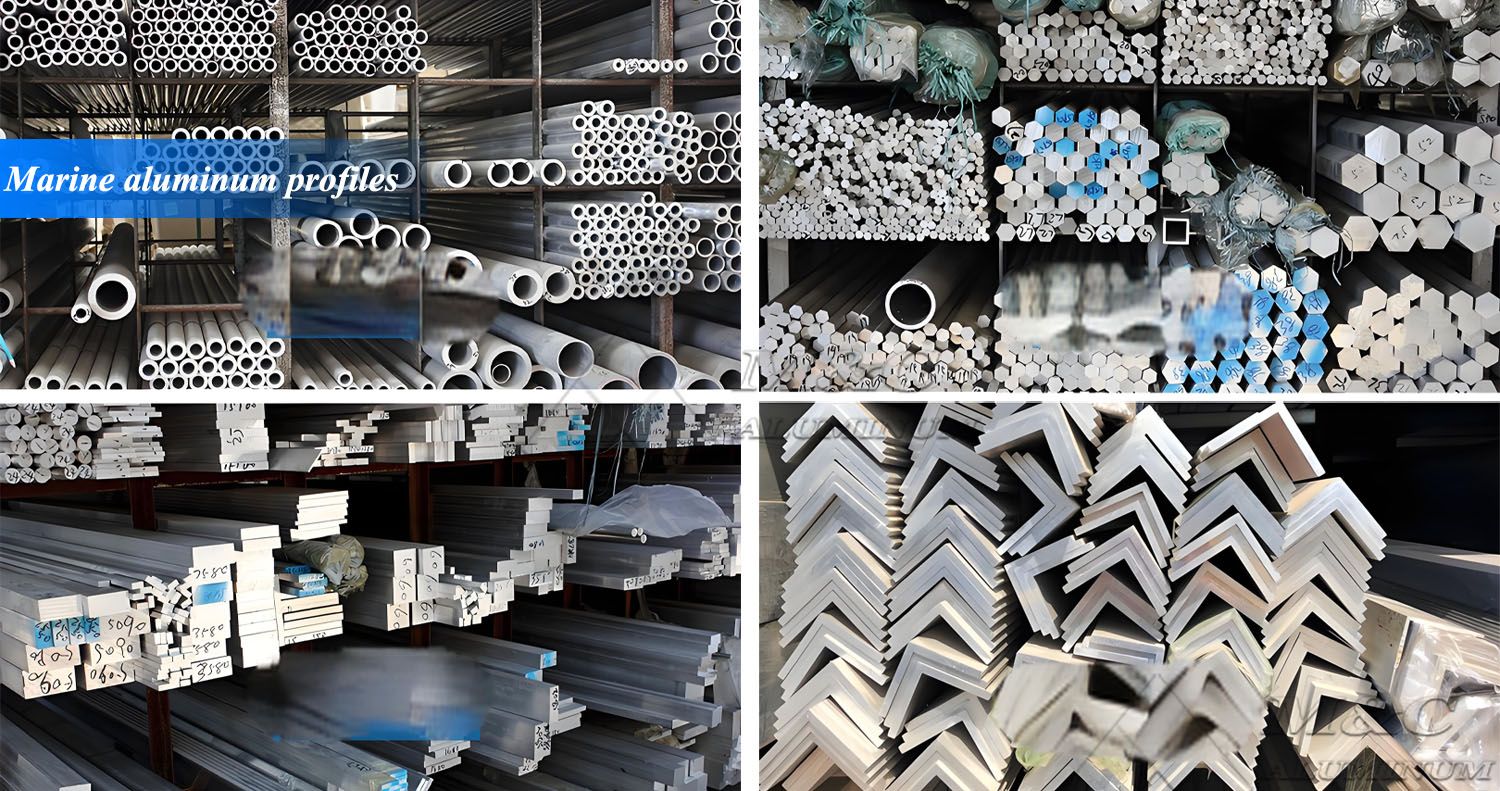

6063 marine aluminum extrusions are high-quality, marine-grade aluminum alloy profiles widely used in ship structures, yacht construction, port facilities, and offshore engineering. 6063 aluminum alloy belongs to the 6xxx series Al-Mg-Si alloys, combining excellent mechanical properties, corrosion resistance, and workability, making it highly suitable for use in humid and salt-spray environments.

Key Features of 6063 Marine Aluminum Profiles

1. Outstanding Corrosion Resistance:

6063 aluminum extrusions can withstand corrosion from seawater, salt spray, and humid climates, significantly extending the service life of ships and marine facilities.

2. Excellent Mechanical Properties:

With moderate strength and good toughness, 6063 extrusions meet structural strength requirements while ensuring easy fabrication and assembly.

3. Lightweight Advantage:

Low density and lightweight characteristics help reduce overall ship weight, improving fuel efficiency and sailing performance.

4. Superior Surface Treatment Capability:

6063 aluminum is ideal for anodizing, painting, or powder coating, enhancing both aesthetics and wear resistance.

5. High Precision Processing:

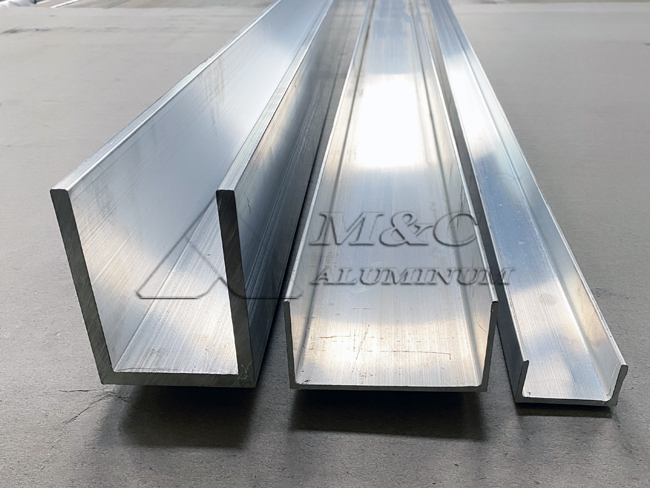

Profiles can be extruded to customer designs with high accuracy, supporting complex cross-sections and customized dimensions.

Product Information

| Alloy Temper | 6063-T5, 6063-T6 |

| Profile Dimensions | Customized according to customer designs; supports complex profiles |

| Surface Treatment | Anodizing (natural, silver, black, etc.), painting, powder coating |

| Length | Standard 6 meters or cut-to-size as requested |

| Samples | Available |

| MOQ | 1–3 tons |

Applications

Hull Structural Components:

Used in small yachts and sailboat frames and keels. Lightweight, high strength, and corrosion-resistant, ensuring stability and better sailing performance.Ship Doors & Window Frames:

Excellent formability allows fabrication of complex shapes. After anodizing, they offer an attractive appearance, corrosion resistance, sealing, and light transmission.Ship Interior Components:

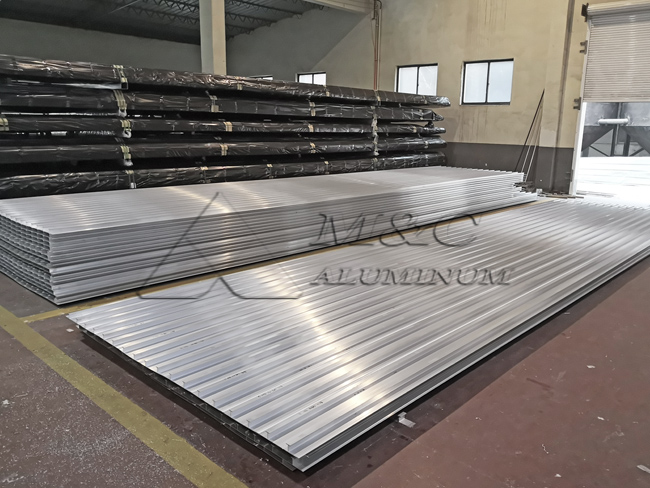

Suitable for trim strips, handrails, ceiling frames, etc. Easy to process, durable against corrosion, and able to maintain both performance and appearance over time.Decks & Superstructures:

Applied in deck frames, railings, and other structures. High strength and weather resistance, combined with lightweight properties, ensure long-term integrity and stability.

Comparison of 6063 Aluminum with Other Alloys

6063 vs. 6061 Aluminum

The 6000 series includes two aluminum alloys, 6061 and 6063. These alloys offer good corrosion resistance and are easily welded. However, each alloy has specific properties that make it suitable for different tasks.

6061 aluminum is stronger than 6063, especially when heat treated to T6 temperature. This additional strength makes 6061 a popular choice for projects requiring strong support, such as bicycle frames and aircraft components.

6063 aluminum is easily formable, allowing for more complex cross-sectional shapes. Its smoother surface quality makes it more suitable for finishing treatments such as anodizing.

Comparison of 6063 vs. 5052 Aluminum

Compared to 5052 marine aluminum, 6063 lacks the strength, especially its resistance to seawater corrosion, of 5052. 5xxx series aluminum alloys are traditionally used as the mainstay of marine aluminum, particularly in critical areas such as hull structures. 6063 aluminum alloy excels in extruding complex cross-sections, superstructures, and interiors.

Comparison of 6063 and 5083 Aluminum

5083 alloy is a high-magnesium alloy characterized by its extremely high strength and excellent corrosion resistance, particularly against seawater corrosion. It is often used in the manufacture of critical structural components of large ships, such as bottom plating, decks, and hull side panels, as it can withstand greater stress and impact.

The strength of 6063 alloy is slightly lower than that of 5083, but its extrudability and surface finish are far superior. This makes 6063 aluminum more suitable for components with complex shapes and high surface requirements, such as marine profiles, interior trim, door and window frames, and some non-critical load-bearing structures. Simply put, 5083 aluminum alloy is the "skeleton" of the ship, while 6063 aluminum alloy is the "muscle" and "skin," complementing each other.