MC Aluminum is a professional supplier and exporter of aluminum pipe fittings for shipyards and marine engineering. Our product range includes aluminum elbows, tees, reducers, and flanges used in shipbuilding and various marine piping systems. Available alloys include 6061-T6, 5083-O, 5052, and 6082-T6, meeting the structural and corrosion-resistance requirements of modern vessels.

Shipboard piping systems cover a wide range of applications, including fresh water and wastewater systems, fuel oil, hydraulics, gas distribution, and outfitting equipment.

Properties of 6061-T6 and 5083-O

6061-T6 is a heat-treatable aluminum alloy strengthened through solution treatment and artificial aging.

Its tensile strength reaches 310 MPa, and yield strength about 276 MPa, giving it exceptional load-bearing capability. This makes 6061-T6 ideal for structural pipe fittings that need to withstand pressure and mechanical stresses on board ships.

5083-O belongs to the non-heat-treatable aluminum-magnesium series and is renowned for its outstanding corrosion resistance, especially in marine and saltwater environments.

Even after welding, it maintains stable mechanical and anti-corrosion performance, making it the preferred choice for pipe sections exposed directly to seawater.

Importance of Aluminum Pipe Fittings in Shipbuilding

1. Lightweight Construction

Aluminum has only one-third the density of steel, greatly reducing vessel weight, improving cruising speed, and lowering fuel consumption.

2. Strong Corrosion Resistance

Aluminum naturally forms a dense oxide film that provides long-term protection in high-salt, high-humidity marine environments, reducing maintenance costs.

3. High Strength & Impact Resistance

Heat-treated aluminum alloys provide the structural reliability needed for dynamic marine loads during navigation, docking, and operation.

4. Easy to Process and Weld

Aluminum pipe fittings are easy to cut, bend, weld, thread, and shape, making them suitable for the complex routing requirements of ship piping systems.

5. Customizable Designs

Elbows, tees, reducers, and flanges can be tailor-made to design drawings, ensuring precision installation for new builds and ship repair projects.

Common Types of Aluminum Pipe Fittings & Their Functions

Aluminum Elbows

Change pipe direction, common angles: 45°, 90°, 180°. Can be welded or threaded, suitable for compact piping layouts on ships.

Aluminum Tees

Branching lines, commonly used in hydraulic, gas, and water systems. Provides uniform flow and structural safety.

Aluminum Reducers

Achieve pipe diameter conversion, facilitating system connection. Improves piping design flexibility.

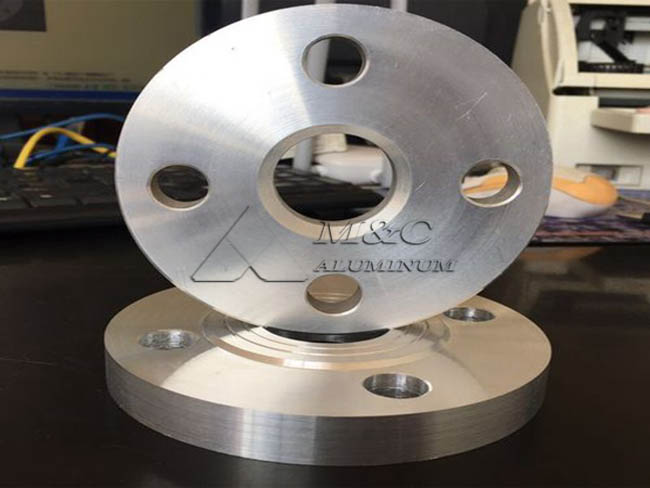

Aluminum Flanges

Aluminum flanges are used for pipe connections; lightweight and corrosion-resistant. Can be used with stainless steel bolts for easy disassembly and maintenance.

Most Common Aluminum Alloys Used in Marine Applications

Aluminum-Magnesium Alloys 5XXX (5083, 5052)

5-series marine aluminum alloys are not heat-treatable and are difficult to cast. However, they have high corrosion resistance, making them ideal for components frequently exposed to seawater.

There are also forged aluminum alloys, including 5052, 5083, and 5754. While they cannot be heat-treatable, they are easy to machine and possess equally excellent corrosion resistance, meeting the requirements of marine environments.

Forged aluminum alloys perform well even at low temperatures, have moderate strength, and can undergo strain hardening.

Al-Mg-Si Alloys - 6XXX (6061, 6063)

6-series marine aluminum alloys are renowned for their excellent decorative and structural properties, as well as outstanding surface finishes. Including alloys 6061, 6082, and 6063, they are commonly used as alloy materials for various indoor and outdoor construction projects.

Aluminum-Magnesium-Silicon alloys are heat-treatable, have moderate strength, are extrudable, and possess high corrosion resistance.

Why Choose MC Aluminum?

1. Extensive Marine Material Experience

Years of supplying high-quality aluminum pipe fittings to domestic and international shipyards, with numerous marine application cases.

2. Multiple Alloy Options

Available in 5083, 5052, 6061, 6082, 6063 to meet strength, corrosion-resistance, and processing requirements for different vessel types.

3. Complete Specifications & Custom Fabrication

Elbows, tees, reducers, and flanges can be manufactured according to drawings, ensuring high dimensional accuracy and easy welding and installation.

4. Full Export Capabilities

Products exported to Europe, America, and Southeast Asia, meeting international shipbuilding standards.

Technical Support & After-Sales Service

We offer alloy selection guidance, engineering recommendations, processing advice, and professional after-sales support.

Original Source: https://www.marinealum.com/a/aluminum-pipe-fittings-for-shipyards-6061-t6-5083-o-alloys.html

Tag: Pipe fittings marine aluminum pipe fittings aluminum elbows aluminum tees aluminum reducers aluminum flanges 5-series marine aluminum alloys 6-series marine aluminum alloys marine aluminum supplier 6061-T6 marine aluminum 5083-O marine aluminum