5052 and 5083 aluminum tubes both belong to the 5xxx series of aluminum-magnesium alloys, offering excellent corrosion resistance and medium to high strength. They are widely used in various industries such as shipbuilding, automotive manufacturing, construction, and petrochemical applications. However, they differ in composition, properties, and applications. Below is a detailed comparison of the two alloys:

Aluminum Tube: 5052 VS 5083

1. Chemical Composition

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Ohter:Each | Other:Total | Al |

| 5052 | 0.25 | 0.4 | 0.1 | 0.1 | 2.2-2.8 | 0.15-0.35 | 0.1 | - | 0.05 | 0.15 | remainder |

| 5083 | 0.4 | 0.4 | .01 | 0.4-1.0 | 4.0-4.9 | 0.05-0.25 | 0.25 | 0.15 | 0.05 | 0.15 | remainder |

As shown in the table above:

5052 Aluminum Tube: The main alloying element is magnesium, with small amounts of chromium, copper, manganese, and zinc. It offers good formability and corrosion resistance.

5083 Aluminum Tube: Compared to 5052, it contains a higher magnesium content and also includes small amounts of manganese and chromium. This results in higher strength and better corrosion resistance.

2. Key Property Comparison

| Property | 5052 Aluminum Alloy | 5083 Aluminum Alloy |

| Alloy Type | Al-Mg series (non-heat treatable) | Al-Mg-Mn series (non-heat treatable) |

| Magnesium Content | 2.2%-2.8% | 4.0%-4.9% |

| Manganese Content | ≤0.10% | 0.40%-1.0% |

| Tensile Strength | 170-305 MPa | 270-317 MPa |

| Yield Strength | ≥70 MPa | 125-228 MPa |

| Elongation | 12%-20% | 12%-15% |

| Hardness | 60 HB (medium) | 70-80 HB (higher) |

| Density | 2.68 g/cm³ | 2.66 g/cm³ |

From the above:

Strength: 5083 offers significantly higher strength due to its greater magnesium and manganese content.

Ductility: 5052 has higher elongation and better formability, suitable for deep drawing and forming; 5083 is harder but slightly more brittle.

3. Corrosion Resistance

5083: Excellent resistance to seawater corrosion (marine grade), with post-weld corrosion resistance retention over 90%. Ideal for ship piping and offshore structures.

5052: Good general corrosion resistance, but prolonged saltwater exposure may cause pitting. Suitable for automotive interiors, non-marine storage tanks, and pipelines.

4. Weldability

5083: Excellent weldability (suitable for MIG and TIG welding), with strength loss in the weld zone under 10%.

5052: Good weldability, but post-weld corrosion protection may be needed.

5. Workability

5052: Due to its good ductility and lower strength, it is easier to cut, stamp, bend, and weld.

5083: With higher strength, it requires more force and advanced techniques during processing.

6. Application Fields

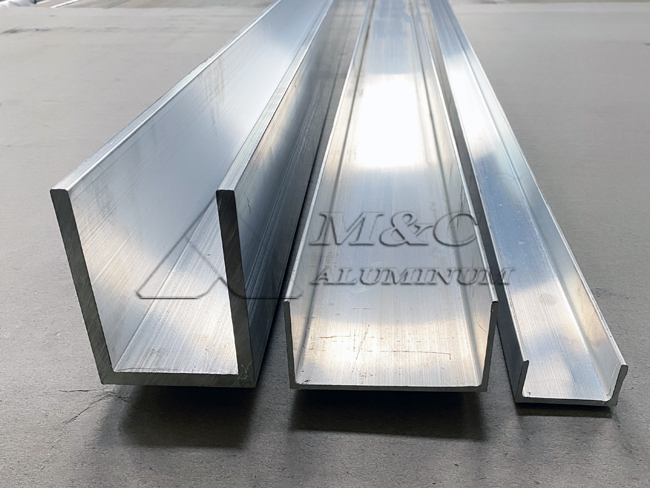

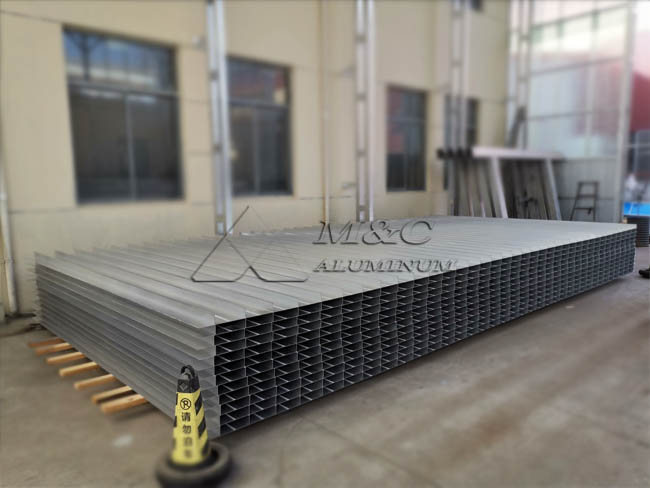

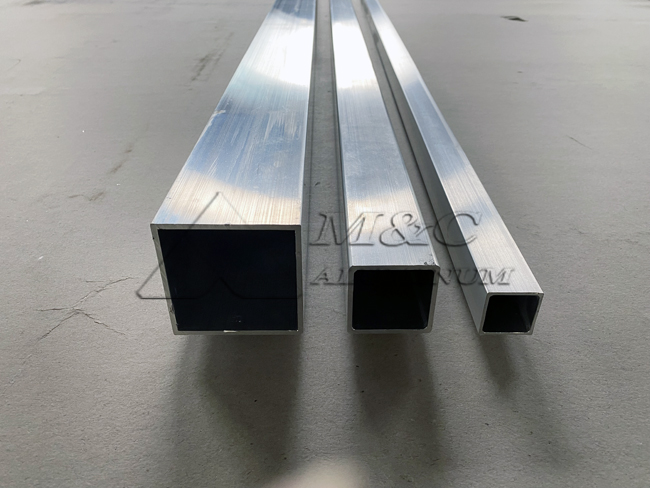

5052 Aluminum Tube: Ideal for parts requiring good appearance and complex shapes, such as automobile body panels, architectural facades, air conditioners, chemical pipelines, and buildings.

5083 Aluminum Tube: Suited for structural parts needing high stress resistance and corrosion protection in harsh environments, such as ship decks, offshore platforms, pressure vessels, military vehicles, marine structures, and industrial equipment frames.

7. Cost

5083 is about 15%–20% more expensive than 5052 due to higher magnesium content and more complex extrusion processes. However, its lower maintenance cost makes it more economical in the long run.

Conclusion:

This comparison summarizes the key differences between 5052 and 5083 aluminum round tubes. We hope this information helps you make a better-informed decision when selecting and applying these materials.