6063 T6 marine aluminum plate is a heat-treatable strengthening alloy that belongs to the Al-Mg-Si series. With its outstanding corrosion resistance, moderate strength, and excellent processing characteristics, it has become an ideal material choice in shipbuilding. Compared with traditional steel, 6063 T6 aluminum offers significant lightweight advantages, with a density of only 2.68 g/cm³, approximately one-third that of steel. This feature allows ship designers to effectively reduce hull weight, improve sailing speed, and increase fuel efficiency.

In the T6 temper (solution heat-treated and artificially aged), 6063 aluminum alloy demonstrates an optimized balance between strength and toughness, enabling it to withstand the multiple stresses encountered in marine environments, including wave impacts, structural vibrations, and load fluctuations. Compared with the T5 temper (air-cooled after extrusion and naturally aged), the T6 temper achieves higher strength and hardness through water quenching and artificial aging.

Another significant feature of 6063 alloy is its resistance to stress corrosion cracking, making it especially suitable for ship structures that operate in long-term marine corrosion environments.

MC Aluminum produces 6063 marine aluminum plates in multiple tempers such as O, T5, T6, T651, and F, all certified by leading classification societies (CCS, ABS, DNV, LR, etc.), as well as ISO 9001 Quality Management and Environmental Management System certifications.

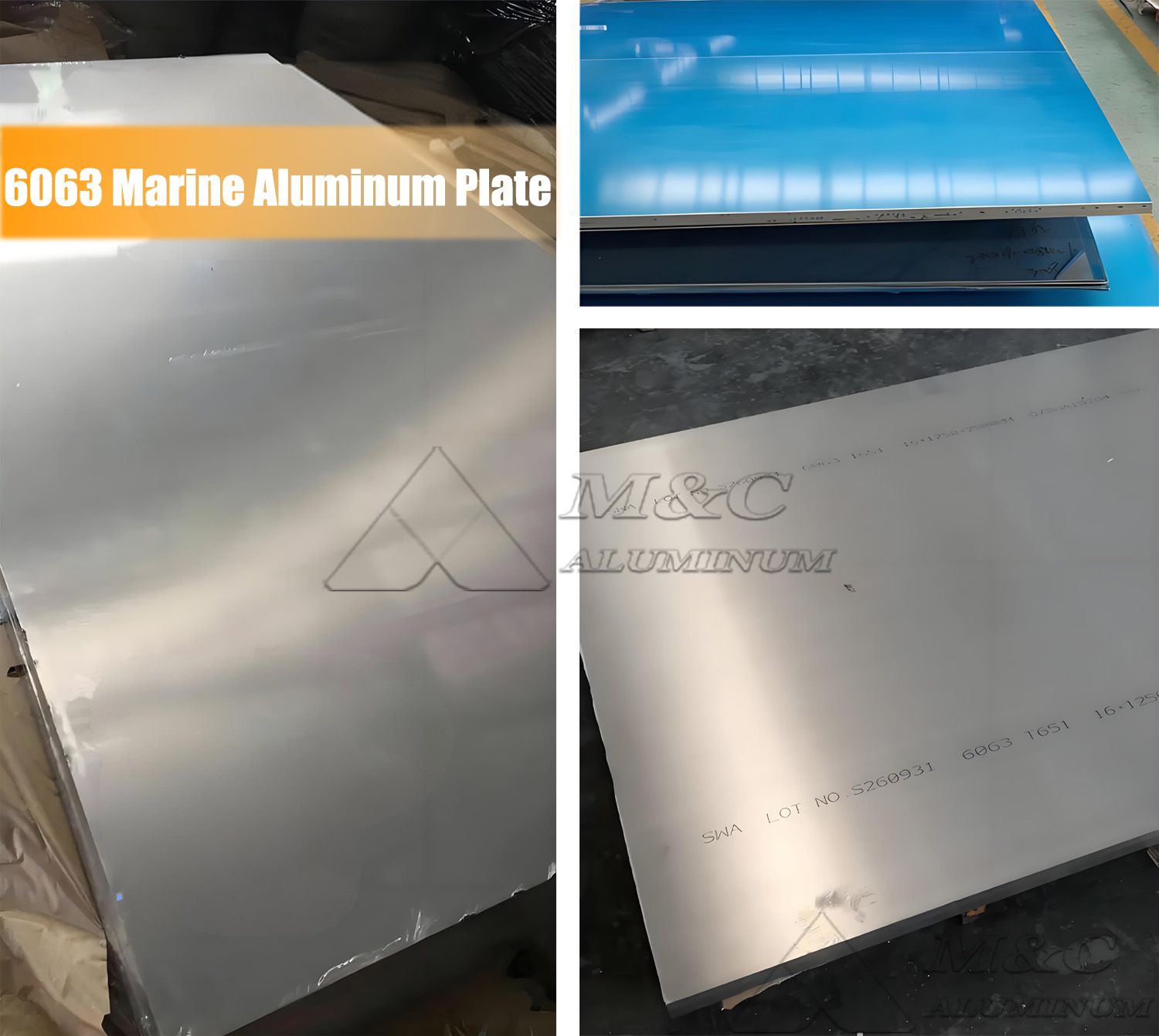

Product Information - 6063 Marine Aluminum Plate

| Alloy | 6063 |

| Tempers | O, T4, T5, T6, T651, F |

| Thickness | 3mm - 50mm |

| Width | 500mm - 2650mm |

| Length | 1000mm - 12000mm (custom cutting available) |

| Surface Treatment | Anodizing, coating, brushing, mirror finish |

Chemical Composition (%)

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Othre | Al |

| 6063 | 0.2-0.6 | 0.35 | 0.1 | 0.1 | 0.45-0.9 | - | 0.1 | 0.1 | 0.15 | remainder |

Mechanical Properties

| Temper | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) | Hardness (HB) |

| T5 | 160 | 110 | 8 | ≥8.5 |

| T6 | 240 | 215 | 12 | 73 |

| O | 90 | 50 | 20 | - |

Key Features of 6063 T6 Marine Aluminum Plate

1. Excellent Corrosion Resistance: Performs well in seawater and humid marine environments, suitable for long-term service at sea.

2. Stable Mechanical Properties: In T6 condition, solution heat treatment and artificial aging significantly enhance strength and hardness, ensuring high reliability in welding and joining.

3. Smooth and Attractive Surface: Outstanding anodizing performance creates a uniform, dense oxide film that improves corrosion resistance and meets decorative needs.

4. Superior Workability: Excellent extrusion performance, suitable for diverse ship structure components such as hulls, decks, and cabins.

5. Eco-Friendly: 100% recyclable, aligning with sustainable and green shipbuilding trends.

Application Fields

Hull plating and deck panels

Cabin interiors, railings, ladders

Offshore platform structures and protective components

Lightweight yacht, speedboat, and fishing vessel components

Comparison with Other Marine Aluminum Alloys

6063-T6 vs. 5083:

5083 is renowned for its high strength and excellent corrosion resistance, making it the preferred choice for large vessel hulls. However, it is more difficult to process and less formable than 6063-T6. For superstructures, cabins, and parts requiring complex shaping, 6063-T6 offers superior formability and ease of processing.

6063-T6 vs. 6061-T6:

Both alloys share similar compositions and heat treatments, with comparable strength. However, 6063-T6 exhibits better extrudability, especially for complex cross-section profiles, while 6061-T6 is more versatile overall. In shipbuilding, 6063-T6 is often chosen for superstructures that demand lightweight design and aesthetic surface finishes.

Why Choose MC Aluminum 6063 Marine Plate?

1. Refined Microstructure: Reduced columnar grain structure and fine grains in the ingot, ensuring strong forging ability.

2. Optimized Alloying: Trace Cu elements enhance hot working plasticity and improve heat treatment strengthening effects.

3. Excellent Corrosion Resistance: No tendency to stress corrosion cracking; welding performance is strong, and corrosion resistance remains stable in welded zones.

4. Superior Surface Quality: Excellent anodizing performance ensures durable, attractive finishes without color change.

Original Source: https://www.marinealum.com/a/premium-6063-t6-marine-aluminum-plate-sheet.html

Tag: 6063 marine grade aluminum plate 6063 marine aluminum sheet 6063 T6 aluminum plate 6063 T6 marine aluminum plate 6061-T6 marine aluminum plate 5083 marine aluminum 6063 aluminum sheet 6063 marine aluminum 6063 T5 aluminum plate 6063 extruded alum