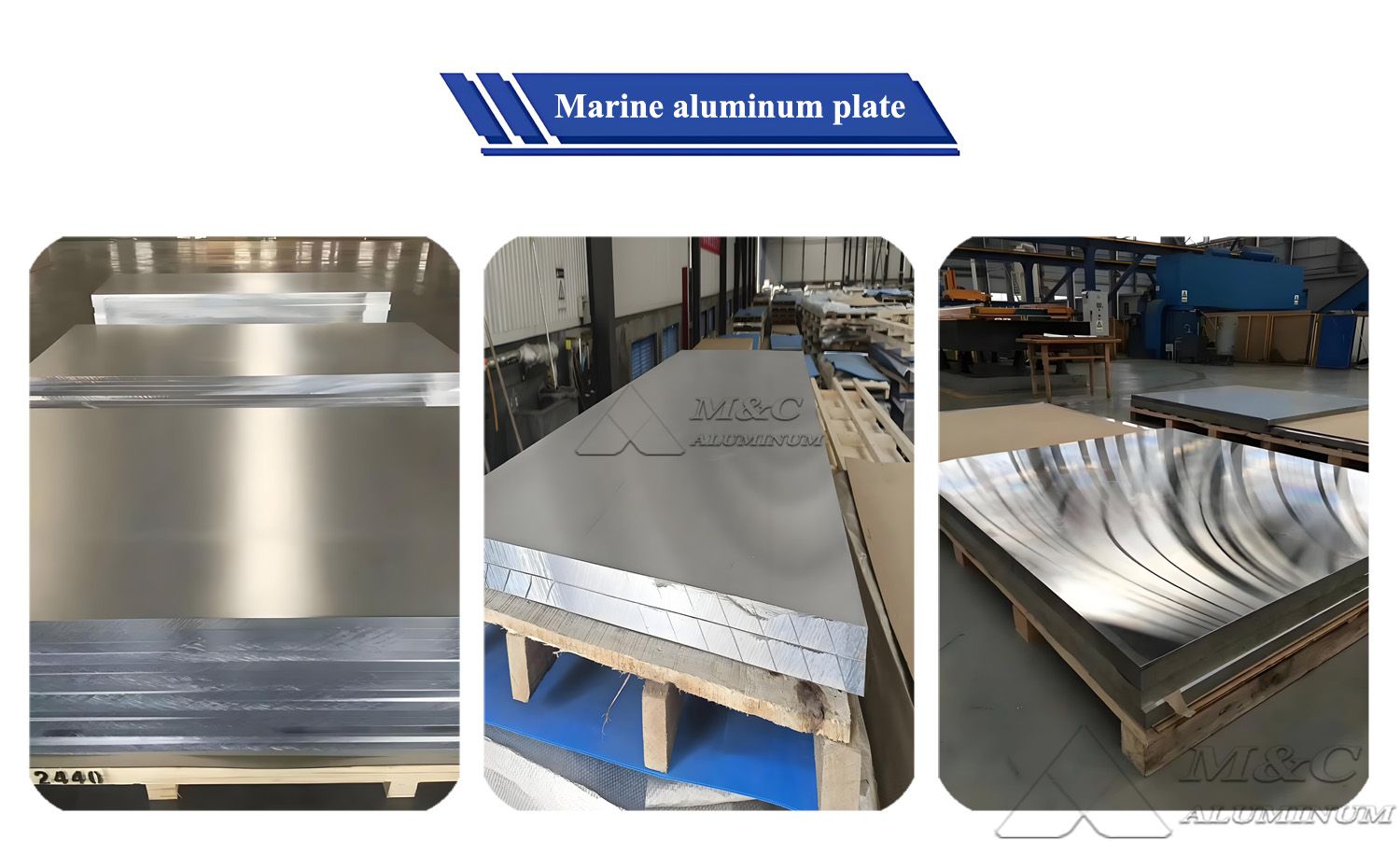

Introduction to 6000 Series Marine Aluminum Plates

6061 Marine Aluminum

6061 aluminum alloy is one of the most representative products of the 6000 series. After hot rolling, it exhibits excellent overall performance. It offers superior weldability, corrosion resistance, and formability, as well as good electroplating ability, toughness, and dimensional stability after machining. The material is dense, free of defects, and widely used in marine applications.

6082 Marine Aluminum

6082 belongs to the 6000 series (Al-Mg-Si) alloys and is a heat-treatable aluminum alloy with medium strength, good weldability, and corrosion resistance. With the rapid development of global shipbuilding, reducing ship weight and increasing speed while replacing steel parts with aluminum alloys has become a key challenge. 6082 combines lightweight properties, medium strength, and excellent corrosion resistance, making it an ideal material for high-speed vessel components.

6063 Marine Aluminum

6063 is an Al-Mg-Si high-plasticity alloy, known for excellent processing performance, outstanding weldability, extrudability, and corrosion resistance. It is easy to polish, coat, and anodize, resulting in a bright and decorative surface. As a typical extrusion alloy, 6063 aluminum plates are widely used in shipbuilding due to their combination of strength, formability, and aesthetic appeal.

The Difference Between T6 and T651 Tempers

Our marine aluminum plates are available in two critical temper conditions to meet different applications:

T6 Temper: Standard solution heat-treated and artificially aged, providing high hardness and strength. This is a cost-effective choice for most structural components requiring strength.

T651 Temper: Based on T6 but with an additional pre-stretching process to eliminate residual stresses caused by heat treatment. This ensures the plate does not deform or warp during precision machining such as cutting or milling. For precision parts, load-bearing beams, or large structural elements, T651 is a more stable and reliable option.

Product Specifications

| Alloys | 6061, 6063, 6082 |

| Tempers | O, T4, T6, T651 |

| Thickness | 3mm - 50mm |

| Width | 1000mm - 3000mm |

| Length | 2000mm - 12000mm, customizable cutting available |

| Surface Treatment | Mill finish / brushed / anodized / coated |

| Certification | Marine classification society approvals (CCS, DNV, ABS, LR, BV) |

| MOQ | 1-3 tons |

Mechanical Properties

| Alloy | Temper | Tensile Strength Rm (MPa) | Yield Strength Rp0.2 (MPa) | Elongation A (%) | Hardness(HB) |

| 6061 | t651 | 260-310 | ≥240 | 10-12 | 95-100 |

| 6082 | 290-340 | ≥250 | 8-10 | 100-110 | |

| 6063 | 240-270 | ≥215 | 12-14 | 75-85 |

Why Choose 6000 Series Marine Grade Aluminum Alloys?

1. Weight reduction: Aluminum density is only one-third that of steel, significantly reducing ship weight and improving speed and fuel efficiency.

2. Excellent corrosion resistance: Outstanding seawater resistance extends vessel lifespan.

3. Superior weldability: Suitable for TIG, MIG, and other welding methods with reliable joint performance.

4. No stress corrosion cracking: Al-Mg-Si alloys in the 6000 series show no susceptibility to SCC.

5. Easy to machine and form: Simple cutting, bending, and forming processes lower manufacturing costs.

6. Aesthetic surface: Can be anodized or coated for enhanced appearance and hardness.

7. Low maintenance cost: Unlike steel, requires less frequent anti-corrosion maintenance.

8. Sustainable & recyclable: 100% recyclable, aligned with green shipbuilding practices.

Application Fields of 6000 Series Marine Aluminum Plates

6061 Alloy: The most widely used marine alloy, balancing strength, corrosion resistance, and weldability. Common applications include small and medium fishing boats, workboats, yacht decks, floating docks, masts, and cabin structures.

6082 Alloy: Known as the “king of structural aluminum alloys,” with higher strength than 6061. Ideal for high-load structures such as high-speed vessels, offshore platforms, naval superstructures, and truss frameworks.

6063 Alloy: With moderate strength but excellent extrudability, it is the top choice for profiles. Used in ship railings, window frames, doors, decorative parts, and small yacht hulls, offering smooth surfaces and aesthetic appeal.

Classification Society Certifications

China Classification Society (CCS)

American Bureau of Shipping (ABS)

Det Norske Veritas (DNV)

Lloyd’s Register (LR)

Bureau Veritas (BV)

As a professional marine aluminum manufacturer, MC Aluminum specializes in producing both 5000 series marine grade aluminum alloys and 6000 series marine grade aluminum alloys. Our products feature flat surfaces, free from black lines, marks, or burrs. With high quality standards, competitive factory-direct prices, fast delivery, and comprehensive after-sales service, we export to over 40 countries and regions worldwide.

Original Source: https://www.marinealum.com/a/marine-grade-6061-6082-6063-t6-t651-aluminum-plate-sheets.html

Tag: 6000 series aluminum plates 6000 series marine aluminum alloys 6000 series marine aluminum plates 6061 marine aluminum plate 6063 marine aluminum plate 6082 marine aluminum plate 6061 T6 marine aluminum plate 6061 T651 marine aluminum plate 6082 T