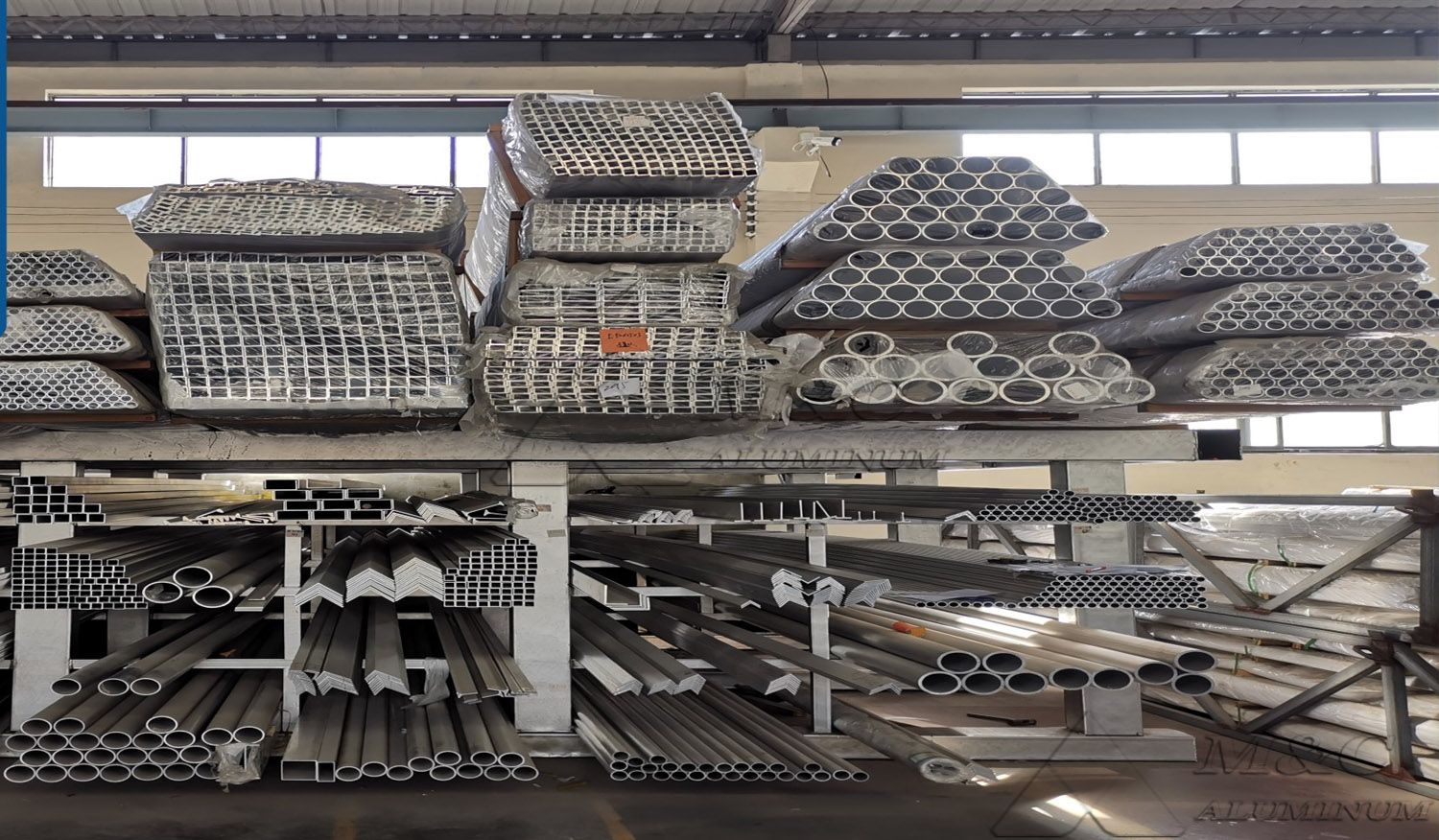

MC Aluminum provides a wide range of extruded aluminum profiles suitable for various shipbuilding applications-from commercial vessels, naval ships, to large barges and floating platforms. Aluminum is easy to process into different shapes and sizes, making it a highly versatile material for marine use. In addition to extruded profiles, we also supply DNV-certified aluminum plates and sheets for marine applications.

The marine aluminum profiles produced by MC Aluminum are commonly made from 6082, 6061, 6063, 5083, and 5052 alloys. Our products are certified by CCS, DNV, NK, ABS, BV, LR, KR, and other classification societies, meeting diverse shipbuilding requirements.

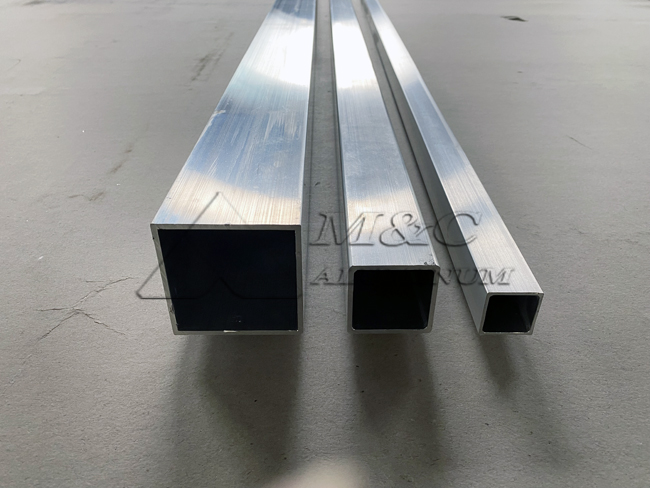

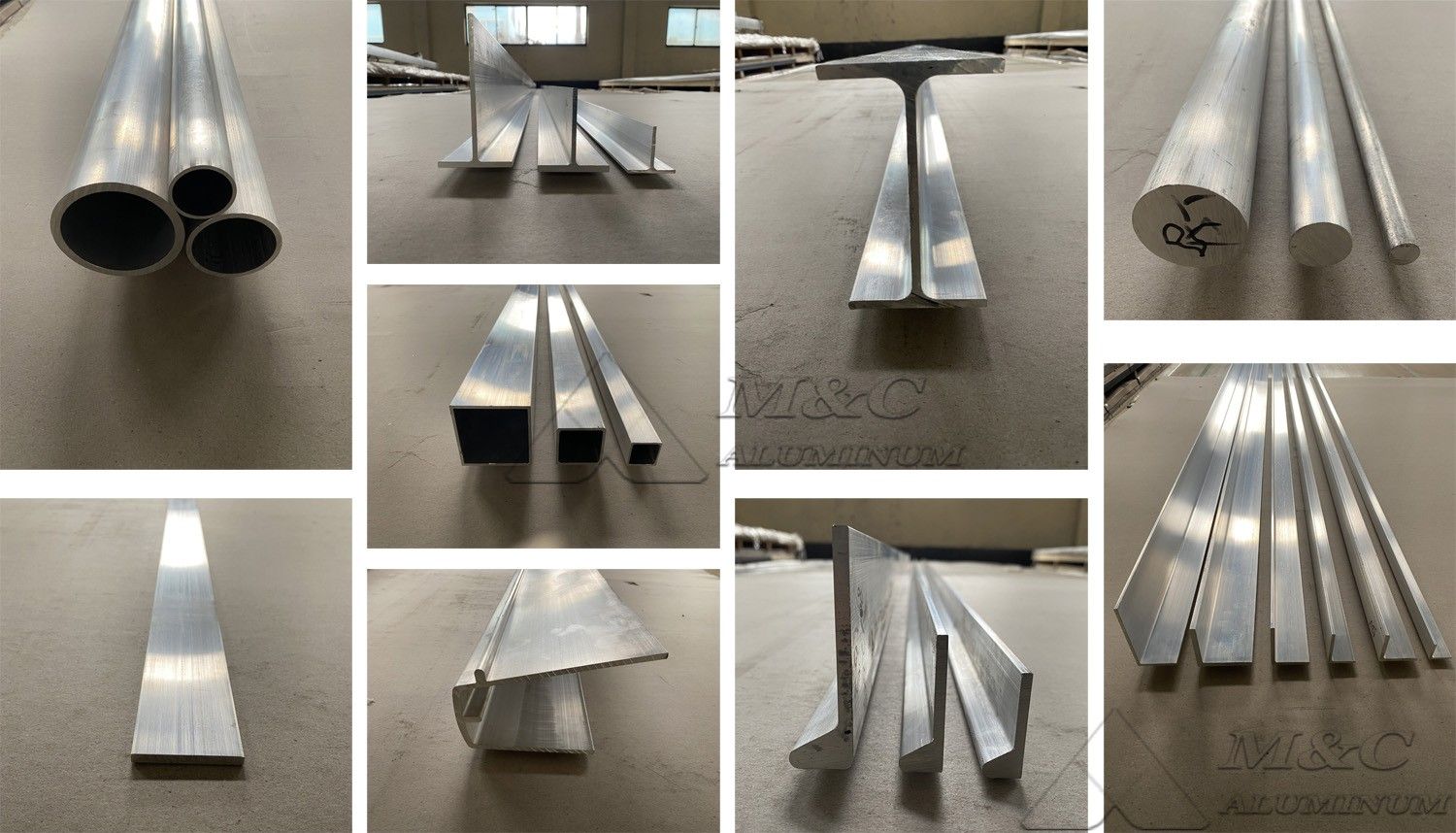

Our Extrusion Product Range

Product Information

| Alloys | 5083, 5052, 6061, 6082, 6063,etc |

| Temper | T5, T6, H111, H116, H321 |

| Shapes | Square tubes, round tubes, angles, Fender, I-type, customized profiles |

| Dimension Range | Round tubes: Ø10mm - Ø500mm Square tubes: 10x10mm - 300x300mm Length: 2m - 12m (customizable) |

| Surface treatment | Anodizing, coating, polishing, marine-grade anti-corrosion coating |

| MOQ | 1-3 tons |

Why Aluminum Extrusions are Ideal for Shipbuilding

1. Excellent Corrosion Resistance

Marine-grade aluminum alloys form a stable oxide film enriched with magnesium, effectively resisting seawater, salt spray, and humid environments.

2. Significant Weight Reduction

Aluminum’s density is only one-third that of steel. Using aluminum profiles greatly reduces vessel displacement and improves fuel efficiency.

3. High Strength and Toughness

With optimized alloy composition and heat treatment, extrusions combine excellent toughness with sufficient strength for ship structures.

4. Superior Workability

Aluminum extrusions can be processed through welding, bending, and forming, making it easier to create complex structures, increase efficiency, and simplify construction.

5. Sustainability & Recycling

Aluminum is 100% recyclable, and remelting requires only about 5% of the energy needed to produce primary aluminum.

6. Non-Magnetic

Marine aluminum reduces magnetic signatures, helping to avoid triggering magnetic mines or interfering with sensitive equipment.

7. Aesthetic and Durable

Surface finishes such as anodizing, painting, and polishing not only provide lasting protection but also deliver attractive appearance, ideal for yachts and passenger vessels.

Applications of Marine Aluminum Extrusions

Shipbuilding: Hull structures, decks, bulkheads, masts, railings, window frames, ladders-used in yachts, fishing boats, cruise ships, and naval vessels.

Offshore Platforms: Walkways, railings, stairs, deck structures, and support frames for offshore oil rigs and wind power platforms.

Port Facilities: Wharf bridges, guardrails, crane beams, and structural parts for container gantry cranes.

As a professional manufacturer of marine aluminum, MC Aluminum provides custom extruded profiles tailored to technical drawings, application fields, and specific client requirements. We offer fast quotations and tailored solutions to meet your shipbuilding needs.

Original Source: https://www.marinealum.com/a/dnv-certified-marine-grade-aluminum-extrusions.html

Tag: Aluminum extrusions marine aluminum profiles marine aluminum alloy extruded aluminum for shipbuilding marine aluminum tube flat bar plate angle T-profile I-profile square tube channel marine aluminum supplier