Traditionally, steel has been the primary material for ship hulls. However, over the past 20 years, aluminum alloys have seen rapid adoption in shipbuilding. 6082 T6 aluminum rods, with their excellent comprehensive performance, have gradually become a popular material for structural boat frames.

6082 aluminum rods belong to the 6000 series (Al-Mg-Si) high-strength alloy family, known for outstanding corrosion resistance, weldability, and machinability. The T6 temper indicates the alloy has undergone solution heat treatment followed by artificial aging to achieve maximum strength. It is widely used in ship structures and superstructures. MC Aluminum can provide MTC 3.2 marine certificates recognized by CCS, ABS, DNV, and LR.

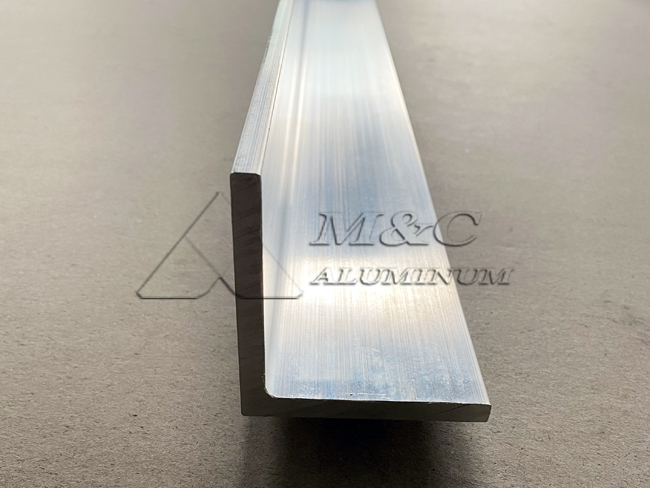

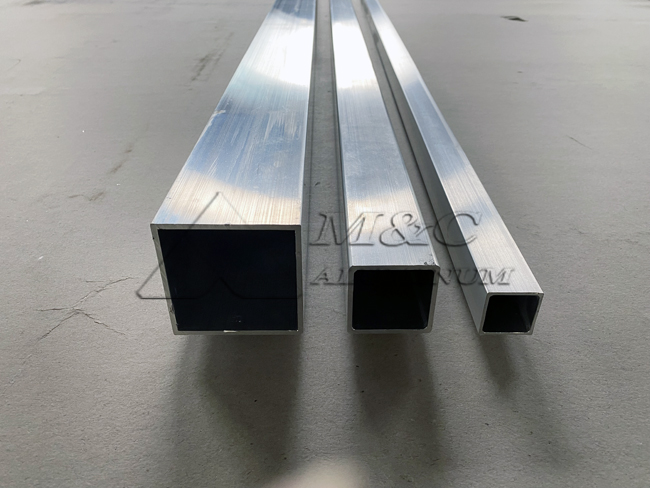

Advantages of 6082-T6 Extruded Aluminum Profiles

1. Lightweight

Aluminum has roughly one-third the density of steel. Replacing traditional steel with 6082 aluminum rods significantly reduces the weight of the hull framework.

2. Corrosion Resistance

6082 T6 aluminum alloy offers excellent resistance to seawater and marine atmospheric corrosion, reducing maintenance costs and extending the vessel's service life.

3. Fatigue Resistance

Ships are subjected to constant wave action, water flow, and vibration. The manganese content in 6082 improves grain structure, enhancing fatigue durability.

4. Machinability and Weldability

Can be joined using conventional arc welding methods. The alloy is also easy to machine into required shapes.

5. Economic Efficiency

Extrusion processes are highly efficient and produce minimal waste, reducing raw material processing costs.

6. Environmental Sustainability

Aluminum is 100% recyclable, aligning with sustainable development goals.

Specifications of 6082-T6 Aluminum Rods

| Diameter Range | Φ8 mm - Φ500 mm |

| Length | 1m, 2m, 6m, customizable |

| Temper | T6 / T6511 (commonly used for marine applications) |

| Surface | Machined, extruded, anodized |

| Certificates | CCS, DNV, ABS, BV, LR, etc. |

| MOQ | 1-3 tons |

Mechanical Properties

| Property | Typical Data |

| Tensile Strength | 290-340 MPa |

| Yield Strength | 240-300 MPa |

| Elongation | 8-12 % |

| Hardness | 95 HB |

| Elastic Modulus | 70 GPa |

| Density | 2.70 g/cm³ |

Available Sizes

| Φ10 | Φ12 | Φ15 | Φ16 |

| Φ20 | Φ25 | Φ30 | Φ40 |

| Φ50 | Φ60 | Φ80 |

Applications of 6082-T6 Marine Extruded Aluminum Rods

1. Hull Structural Frames

6082 T6 aluminum rods play a central role in the hull structure. Due to their high strength, corrosion resistance, and weldability, they are an ideal choice for ship structural components.

2. Ship Superstructures

Various ship superstructures, such as masts, funnels, bridges, gun mounts, and lifting devices, increasingly use aluminum alloys.

For superstructures, large-width extruded wall panels are the most commonly used aluminum components, and 6082 T6 aluminum is the premium material for manufacturing these panels.

3. Other Marine Components

Deck fittings and supporting structures

Internal cabin frameworks and bulkheads

Ship furniture and decorative components

Pipe support systems

Original Source: https://www.marinealum.com/a/6082-t6-aluminum-rod-for-structural-boat-frames.html

Tag: 6082-T6 extruded aluminum profile 6082-T6 marine extruded aluminum rod 6082 T6 aluminum rod marine aluminum profile 6082 marine aluminum 6082-T6 marine aluminum alloy 6082 aluminum extrusion extruded aluminum profile