On the vast, rolling seas, a yacht is not only a symbol of speed and status but also a testament to modern engineering aesthetics. Among all the yacht details, railings serve as the last line of protection for passengers' safety while simultaneously shaping the yacht's visual lines.

6082 T6 marine aluminum tubes, with excellent mechanical properties, corrosion resistance, and favorable machinability, are increasingly becoming the preferred material for yacht railing structures.

Overview of 6082 Aluminum Alloy

6082 belongs to the Al-Mg-Si series and is a medium-to-high strength structural aluminum alloy. It is widely used in European marine and offshore engineering due to its outstanding corrosion resistance, earning it the nickname "marine-grade aluminum." Compared to the commonly used 6061 alloy, 6082 exhibits superior strength and deformation resistance, making it ideal for components subject to external loads and long-term use.

In the T6 temper, 6082 aluminum undergoes solution heat treatment and artificial aging, resulting in a stable microstructure and an optimal balance of mechanical and corrosion-resistant properties. This makes it particularly suitable for marine tubing that demands high strength and dimensional stability.

Core Performance Advantages of 6082 T6 Marine Aluminum Tubes

High Strength and Structural Reliability

6082 T6 aluminum tubes offer high yield and tensile strength, capable of withstanding impact loads, passenger leaning forces, and wave forces during yacht operation. This ensures that the railing system remains deformation-free and secure over long-term use.Excellent Corrosion Resistance in Marine Environments

The alloy's optimized magnesium and silicon composition gives it excellent corrosion resistance in marine atmospheres. Combined with anodizing or powder coating, its salt spray resistance is further enhanced, making it suitable for long-term exposure to seawater, humid air, and UV radiation.Lightweight Advantage

Compared to stainless steel railings, 6082 T6 aluminum tubes are significantly lighter while maintaining structural strength. This reduces overall yacht weight, improves sailing efficiency and handling, and also facilitates installation and maintenance.Superior Machinability and Formability

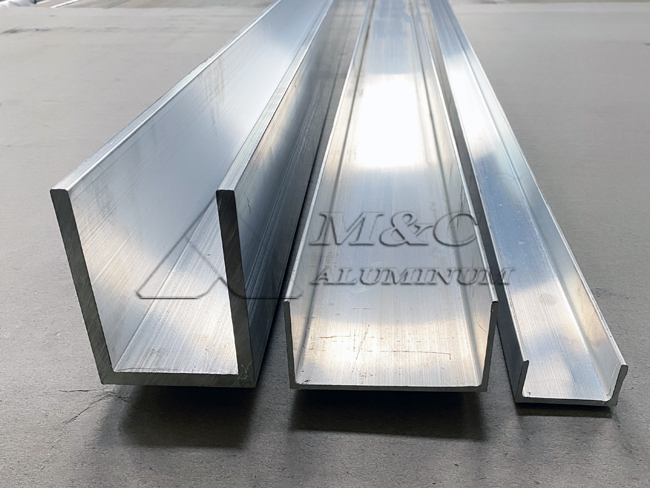

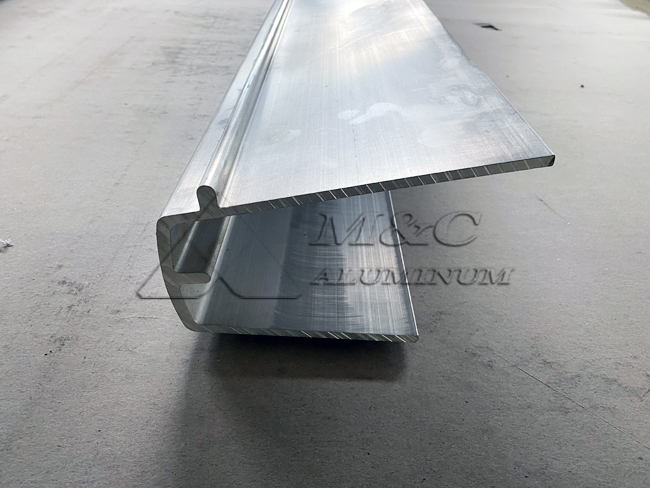

6082 aluminum tubes have excellent extrusion performance, allowing customization of outer diameters, wall thicknesses, and cross-sectional shapes. Their welding and post-machining performance is also excellent, enabling complex railing structures and connectors to meet diverse yacht design requirements.

Technical Specifications of Marine Aluminum Tubes

| Alloy | 6082 |

| Temper | T6 |

| Outer Diameter | 20 - 120 mm |

| Wall Thickness | 1.5 - 6.0 mm |

| Standard Length | 6 m (customizable) |

| Cross-section | Round tube / customized profiles |

| Surface Finish | Anodized, powder-coated, polished |

| Typical Applications | Yacht railings, guardrails, handrails |

| MOQ | 1-3 tons |

Mechanical Properties (T6)

| Tensile Strength (Rm) | ≥ 290 MPa |

| Yield Strength (Rp0.2) | ≥ 240 MPa |

| Elongation (A) | ≥ 8% |

| Brinell Hardness (HB) | ≈ 95 |

Physical Properties

| Density | 2.70 g/cm³ |

| Elastic Modulus | 69 GPa |

| Coefficient of Thermal Expansion (20-100°C) | 23.4 ×10⁻⁶ /K |

| Thermal Conductivity | ≈ 180 W/(m·K) |

Application Advantages of 6082 T6 Aluminum Tubes for Yacht Railings

In yacht railing systems, the material must meet structural requirements while also considering aesthetics and user safety. 6082 T6 aluminum tubes offer the following advantages:

Metallic Elegance: Polished or brushed 6082 aluminum tubes exhibit a refined silver metallic sheen, harmonizing beautifully with white fiberglass yacht hulls.

Color Customization: Powder coating allows railings to be customized in any color, matching the yacht's branding or design theme.

Comfortable Touch: Compared to stainless steel, aluminum conducts heat less aggressively under direct sunlight, providing a smoother and more comfortable surface.

Ease of Installation: Tubes are dimensionally stable with high straightness, facilitating on-site installation.

How to Ensure High-Quality 6082 T6 Aluminum Tubes

Not all 6082 aluminum tubes meet marine standards. When selecting materials, pay attention to:

Certification Standards: Ensure products are certified by reputable institutions such as DNV (Det Norske Veritas), LR (Lloyd's Register), or CCS (China Classification Society).

Wall Thickness Consistency: High-quality extrusion ensures precise wall thickness, preventing tube collapse during bending operations.

Surface Quality: The surface should be free of cracks, peeling, corrosion spots, or bubbles to avoid defects after anodizing.

Original Source: https://www.marinealum.com/a/6082-t6-marine-aluminum-tube-suitable-for-yacht-railings.html

Tag: 6082 T6 marine aluminum plate 6082 marine aluminum tube 6082 marine aluminum 6082 aluminum alloy tube marine-grade aluminum alloy marine aluminum profiles marine extrusion aluminum aluminum tube manufacturer marine aluminum supplier