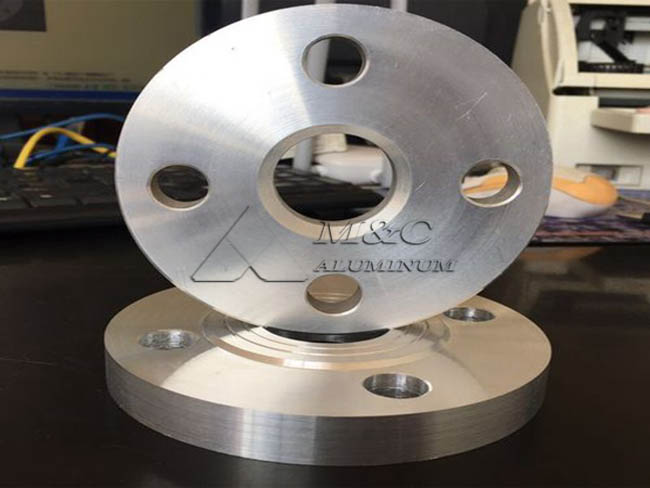

Flanges in piping systems are used to connect pipe sections and valves while allowing for convenient maintenance. Among various flange types, weld neck flanges are recognized as one of the most reliable and widely used solutions. Common materials include steel and aluminum. Thanks to their lightweight characteristics, high strength, and excellent resistance to marine corrosion, aluminum weld neck flanges are increasingly becoming the preferred choice for shipbuilders and shipyards.

What Is an Aluminum Weld Neck Flange?

A weld neck flange features a long, tapered hub that is connected to the pipe by butt welding. This design allows for a smooth transition of stress from the flange to the pipe, significantly reducing stress concentration. As a result, weld neck flanges are widely used in high-pressure, high-temperature, and high-reliability applications.

When manufactured from aluminum alloys such as 5083, 5086, or 6061, weld neck flanges maintain structural strength while offering enhanced weight reduction and superior corrosion resistance.

Key Advantages of Aluminum Weld Neck Flanges for Marine Use

1. Excellent Corrosion Resistance

Aluminum alloys naturally form a dense oxide layer when exposed to air or seawater, providing effective protection against electrochemical corrosion. Compared with stainless steel and other materials, aluminum flanges maintain structural integrity over long service periods, significantly reducing maintenance costs.

2. Lightweight Construction

Aluminum has only about one-third the density of steel, while its strength can be significantly improved through alloying. Using aluminum weld neck flanges on ships reduces overall structural weight, improves fuel efficiency, and increases effective payload capacity.

3. Good Thermal Conductivity

Aluminum flanges dissipate heat efficiently, helping to prevent deformation or damage caused by thermal stress at connection points. This advantage is particularly valuable in high-temperature areas such as marine engines and cooling systems.

4. Flexible and Reliable Welding Processes

Aluminum flanges can be joined using MIG (Metal Inert Gas) or TIG welding, as well as explosion bonding in specific applications. These mature processes meet the stringent precision and strength requirements of modern shipbuilding.

5. Outstanding Cost Effectiveness

With relatively low material cost, long service life, and minimal maintenance requirements, aluminum weld neck flanges represent a highly economical solution. Compared with highly corrosion-resistant materials such as stainless steel or titanium, aluminum flanges offer superior cost-performance balance.

6. Streamlined Design

Aluminum weld neck flanges feature a clean and streamlined appearance, offering aesthetic advantages in addition to functionality. Compared with bulkier flange types, they are less visually intrusive and give piping systems a more refined and professional look.

Typical Marine Application Scenarios

Ship cooling water and ballast water piping systems

Marine ventilation and air-conditioning systems

Fuel oil, lubricating oil, and other light-medium pipelines

Aluminum alloy piping for superstructures and decks

Offshore engineering platforms and offshore wind power installations

Selection of Marine Aluminum Flanges

When selecting aluminum weld neck flanges for marine use, alloy grade and temper are critical considerations. Common marine-grade aluminum alloys include 5086, 5083, and 6061.

To ensure long-term reliability, priority should be given to products that comply with international classification society standards, such as DNV, ABS, or LR approvals. During installation, welding consumables and techniques compatible with aluminum alloys must be used, and direct contact with dissimilar metals should be avoided to prevent galvanic corrosion.

Flange Materials Comparison: Aluminum vs. Traditional Materials

| Performance Indicator | Aluminum Weld Neck Flanges (5083 / 6061) | Carbon Steel Weld Neck Flanges | Stainless Steel Weld Neck Flanges (316L) |

| Weight | Lightest | Very heavy | Heavy |

| Seawater Corrosion Resistance | Excellent | Very poor, requires coating | Outstanding |

| Initial Cost | Medium | Low | High |

| Life-Cycle Maintenance Cost | Very low | High (frequent rust removal & repainting) | Low |

| Welding Process | Requires professional MIG/TIG welding | Mature and simple | Relatively mature |

Original Source: https://www.marinealum.com/a/advantages-of-using-aluminum-weld-neck-flanges-in-marine-applications.html

Tag: Marine aluminum flanges aluminum pipe flanges aluminum flanges weld neck flanges piping fittings aluminum alloy flanges 5086 aluminum flanges 6061-T6 aluminum flanges 5083 aluminum flanges raised face flanges marine piping fittings aluminum wel