What is Extruded Aluminum?

Extrusion is one of the most common aluminum forming processes. First, a precision die is designed to match the required shape profile for the application. Heated aluminum billets (400-500°C) are then forced through the die cavity under high pressure, producing the desired cross-sectional shape.

Extruded aluminum offers numerous advantages: lightweight, cost-effective, excellent oxidation resistance, good thermal conductivity, corrosion resistance, non-magnetic properties, and resistance to rusting compared with steel. For these reasons, it is widely used in the automotive, marine, construction, and industrial sectors.

At MC Aluminum, our marine extruded profiles are lightweight, corrosion-resistant, and fatigue-resistant, making them an essential material for marine environments. They are extensively applied in ship decks, roofs, guardrails, keels, and ribs.

Standard and Custom Marine Extruded Aluminum

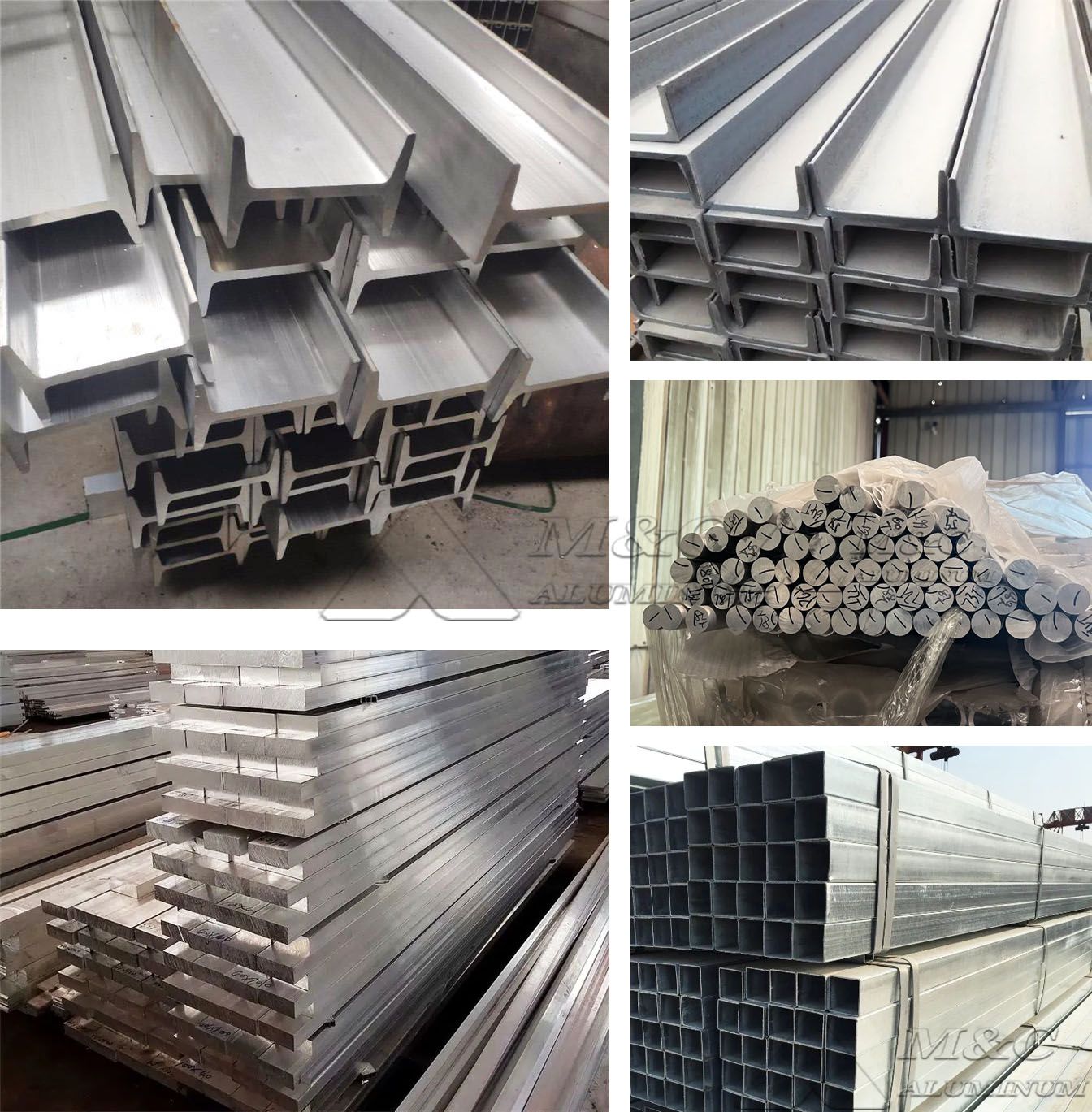

MC Aluminum provides two main types of aluminum extrusions for the marine industry:

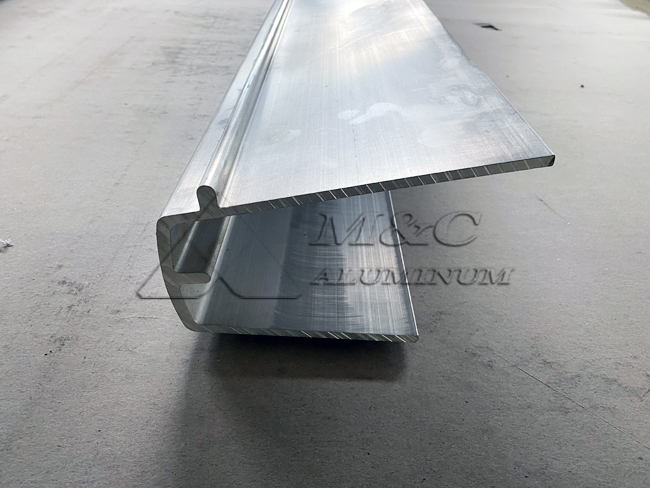

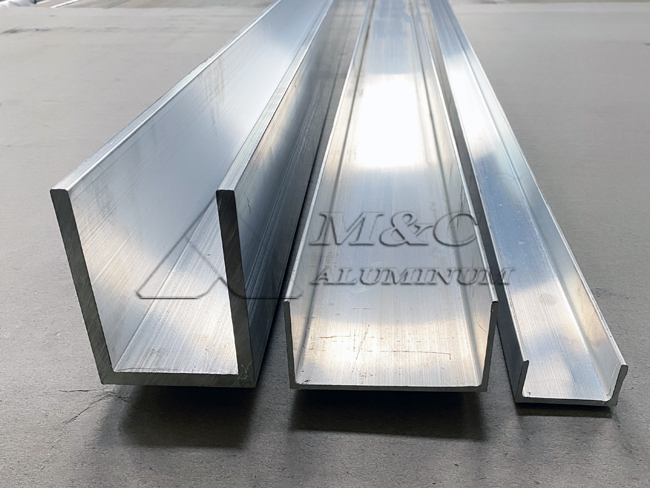

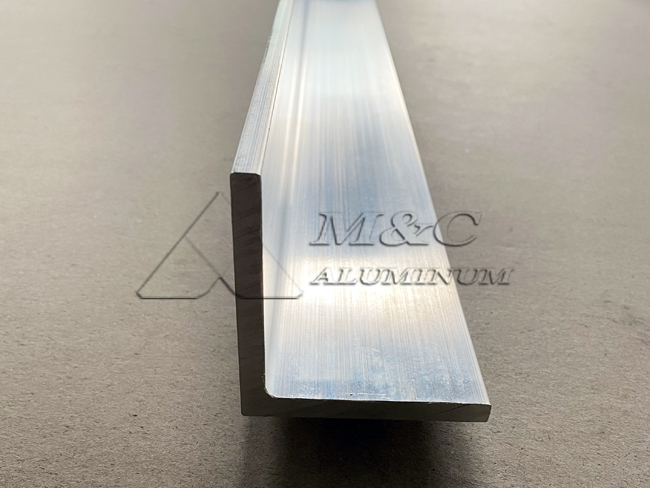

Standard Profiles: Includes basic shapes such as hollow bars, solid rods, T-sections, flat bars, channels, and hollow tubes.

Custom Profiles: Tailor-made extrusions based on technical drawings, application fields, and customer-specific requirements. We provide fast quotations and customized solutions.

We also offer surface treatments such as anodizing, powder coating, and painting to enhance durability and corrosion resistance.

Common Marine-Grade Extrusion Alloys & Shapes

Marine-grade aluminum extrusions are typically produced from 5xxx series (Al-Mg alloys) and 6xxx series (Al-Mg-Si alloys):

5xxx Marine Alloys (e.g., 5083, 5052, 5754): Exceptional corrosion resistance, ideal for hulls, decks, and ribs exposed to seawater.

6xxx Marine Alloys (e.g., 6061, 6082, 6063): Higher strength, suitable for load-bearing frames, outfitting parts, deck structures, and port equipment.

Basic Shapes Available:

Profiles, tubes, T-type, I-type, angular, trough,fender, flat bars, FSW panels, and more. Through strict process control and technical optimization, we achieve high dimensional accuracy and superior surface quality, meeting the demanding requirements of marine applications.

Advantages of Aluminum Profiles in Marine Applications

1. Lightweight & Efficient: High strength-to-weight ratio, reducing vessel weight (e.g., up to 30% weight reduction for yachts), improving fuel efficiency and speed.

2. Corrosion Resistance: Naturally corrosion-resistant; with special treatments, can withstand long-term exposure to marine environments.

3. Design Flexibility: Extrusions can be produced in a wide range of shapes, meeting customized marine design needs.

4. High Strength & Reliability: Suitable for critical load-bearing structures, ensuring vessel safety and integrity.

5. Fire Resistance & Insulation: Excellent fire resistance and lower thermal conductivity improve onboard comfort.

6. Modern Aesthetic: Sleek appearance with customizable finishes and colors for enhanced visual appeal.

7. Sustainability: Fully recyclable, reducing environmental impact. Recycled aluminum requires significantly less energy compared with primary production.

Applications of Marine Aluminum Profiles

Ship Structures: Decks, bulkheads, ribs, ladders, railings

Offshore Equipment: Platforms, walkways, frames, guardrails

High-Speed Boats & Yachts: Lightweight hulls, interior skeletons

Naval Vessels: Stealth aluminum alloy structures, reducing weight and improving maneuverability

Port Facilities: Floating docks, gangways, fender systems

How much does marine-grade extruded aluminum cost per ton?

The price of aluminum extrusions is influenced by many factors, including the price of the aluminum ingot at the time of shipment, the alloy number, processing fees, and ocean freight. Prices also vary between manufacturers.

How to Get an Accurate Quotation?

To provide you with a precise and competitive quote, please share:

Product drawings or sketches: Dimensions, cross-sectional shapes, wall thickness.

Required alloy grade: Such as 5083, 6061, etc.

Application scenario: To recommend the most suitable solution.

Estimated order volume: For calculating the most cost-effective pricing.

Contact our sales team directly, and we will arrange for our experts to provide personalized consultation and a transparent, detailed quotation.

MC Aluminum specializes in the production of extruded aluminum profiles. We offer the best service in the industry and the most comprehensive product capabilities, covering press sizes and tonnages (direct and indirect extrusion), alloy selection, disc sizes, profile types and "blanks," and producing the largest outside diameter (OD) sizes and the highest precision tolerances in the industry.

Original Source: https://www.marinealum.com/a/marine-extruded-aluminum-manufacturer-supplier-and-exporter.html

Tag: Extruded Aluminum Aluminum Profiles Aluminum Extrusions Aluminum Extruded Parts Marine Aluminum Profiles Marine-Grade Extruded Aluminum Custom Aluminum Profiles Aluminum Stock Aluminum Profile Manufacturer Aluminum Profile Price