In the shipbuilding and offshore engineering sectors, strength, corrosion resistance, and workability are the core indicators for evaluating the suitability of materials. The 6061 T651 marine-grade aluminum plate, a high-quality aluminum-magnesium-silicon alloy, is widely used in the construction of yachts, speedboats, workboats, fishing vessels, and offshore platforms thanks to its excellent mechanical properties, outstanding corrosion resistance, and good welding performance.

MC Aluminum’s 6061 marine aluminum plates have passed certifications from CCS (China Classification Society), BV (Bureau Veritas), DNV, LR, and ABS, ensuring reliability and safety in the shipbuilding industry.

Characteristics of 6061 T651 Aluminum Plate

6061 aluminum alloy belongs to the Al-Mg-Si series. Through solution heat treatment and artificial aging, it achieves high strength and stable physical properties, making it especially suitable for manufacturing hull structures, decks, and marine fittings.

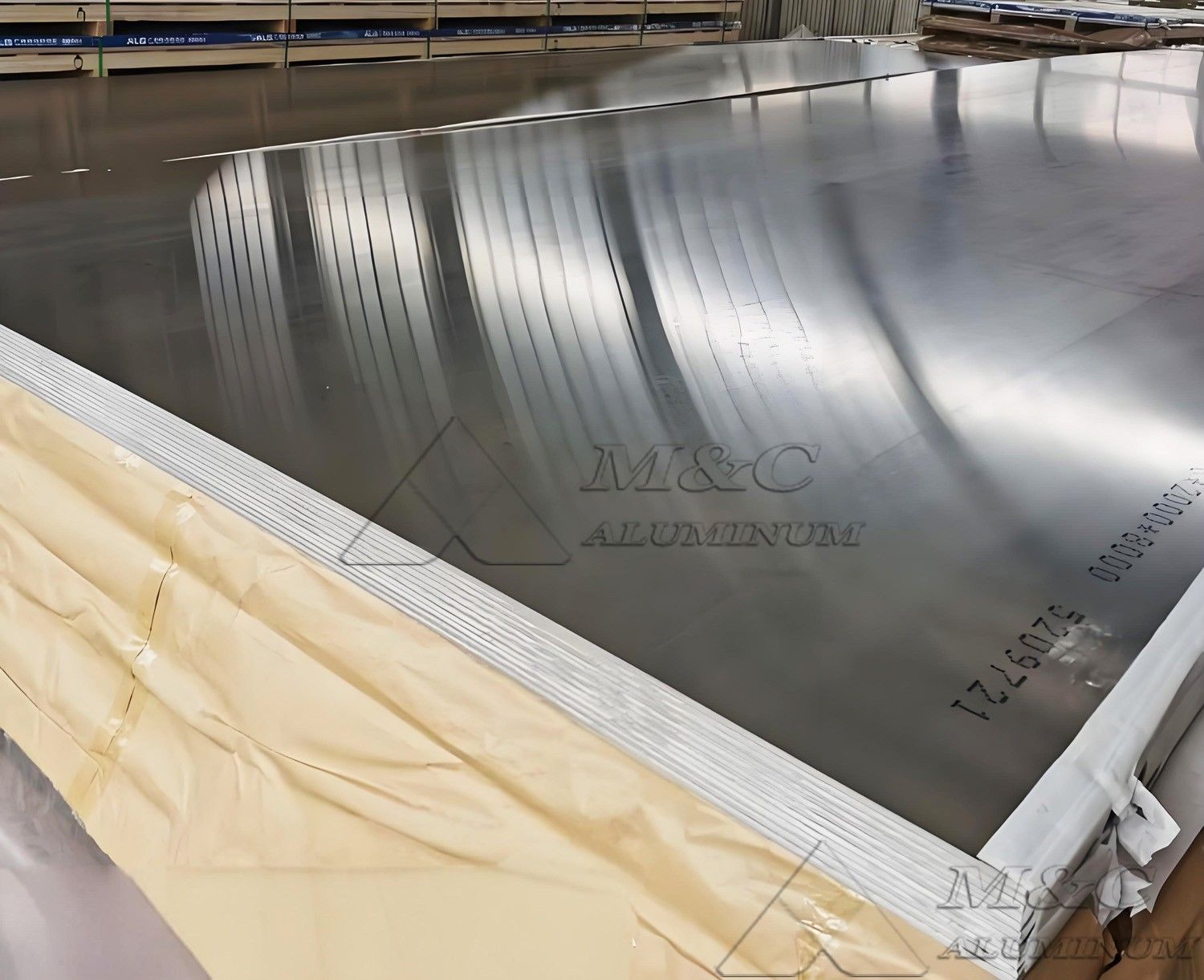

Chemical composition: Mainly contains magnesium (Mg) 0.8–1.2% and silicon (Si) 0.4–0.8%, with small amounts of copper (Cu) and chromium (Cr) to balance strength and corrosion resistance. A key advantage of this material is that it undergoes pre-stretching treatment to eliminate internal stress, ensuring minimal deformation during processing — particularly important for precision marine components.

T651 temper: Based on T6 heat treatment, it is further stress-relieved by stretching, effectively preventing deformation and warping during subsequent machining.

Lightweight density: About 2.70 g/cm³, which helps reduce hull weight, increase sailing speed, and improve fuel economy.

Mechanical Properties of 6061 T651

| Property | Standard Value |

| Tensile Strength | ≥ 310 MPa |

| Yield Strength | ≥ 276 MPa |

| Elongation | ≥ 12% |

| Brinell Hardness | 95 HB |

| Fatigue Strength | 96.5 MPa |

| Shear Strength | 207 MPa |

Key Advantages of T651 Marine Aluminum Plate

1. Outstanding Corrosion Resistance: Strong resistance to seawater corrosion, extending vessel service life and reducing maintenance costs.

2. High Strength & Lightweight: Comparable to certain steels in strength, yet only one-third the density, enhancing speed, fuel efficiency, and load capacity.

3. Excellent Workability: Easy to cut, weld, and bend, offering design flexibility. Excellent weldability ensures structural integrity.

4. Good Fatigue Resistance: Withstands alternating stress, reducing fatigue cracking risk and improving navigational safety.

5. Eco-Friendly & Recyclable: 100% recyclable, aligning with sustainable development principles.

Applications of 6061 Marine Aluminum Plate

Offshore Platforms & Floating Bridges: Designed for humid, high-salt spray environments.

Hull Framework: Provides lightweight structural support, reducing overall weight and improving fuel efficiency.

Decks & Porthole Fittings: Highly weather-resistant and suitable for high-load areas.

Marine Interiors & Piping Systems: Easily polished or anodized for both aesthetic and functional purposes.

Why Choose Us?

1. Direct Manufacturer: Supply 6061-T651 and 6061-T6 marine aluminum plates with customized sizes and surface treatments.

2. Comprehensive Quality Testing: Full range of tests including chemical composition analysis, ultrasonic flaw detection, and mechanical property evaluation.

3. Global Shipping: Extensive export experience with products shipped to Southeast Asia, Europe, the Americas, and beyond.

4. High Cost-Performance: Stable supply and competitive pricing to help customers reduce procurement costs.

Original Source: https://www.marinealum.com/a/6061-t651-marine-grade-aluminum-plate-sheet.html

Tag: 6061 marine aluminum 6061 marine aluminum plate 6061-T651 aluminum plate marine aluminum alloy plate 6061 T651 marine-grade aluminum plate marine aluminum plate manufacturer 6061-T651 marine aluminum alloy plate ship aluminum plate supplier