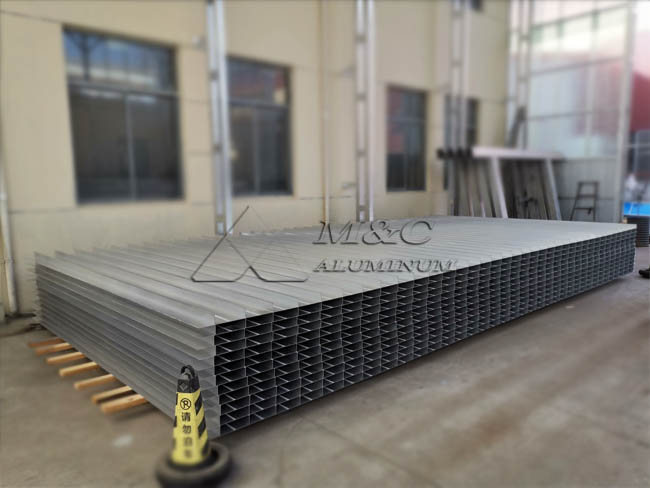

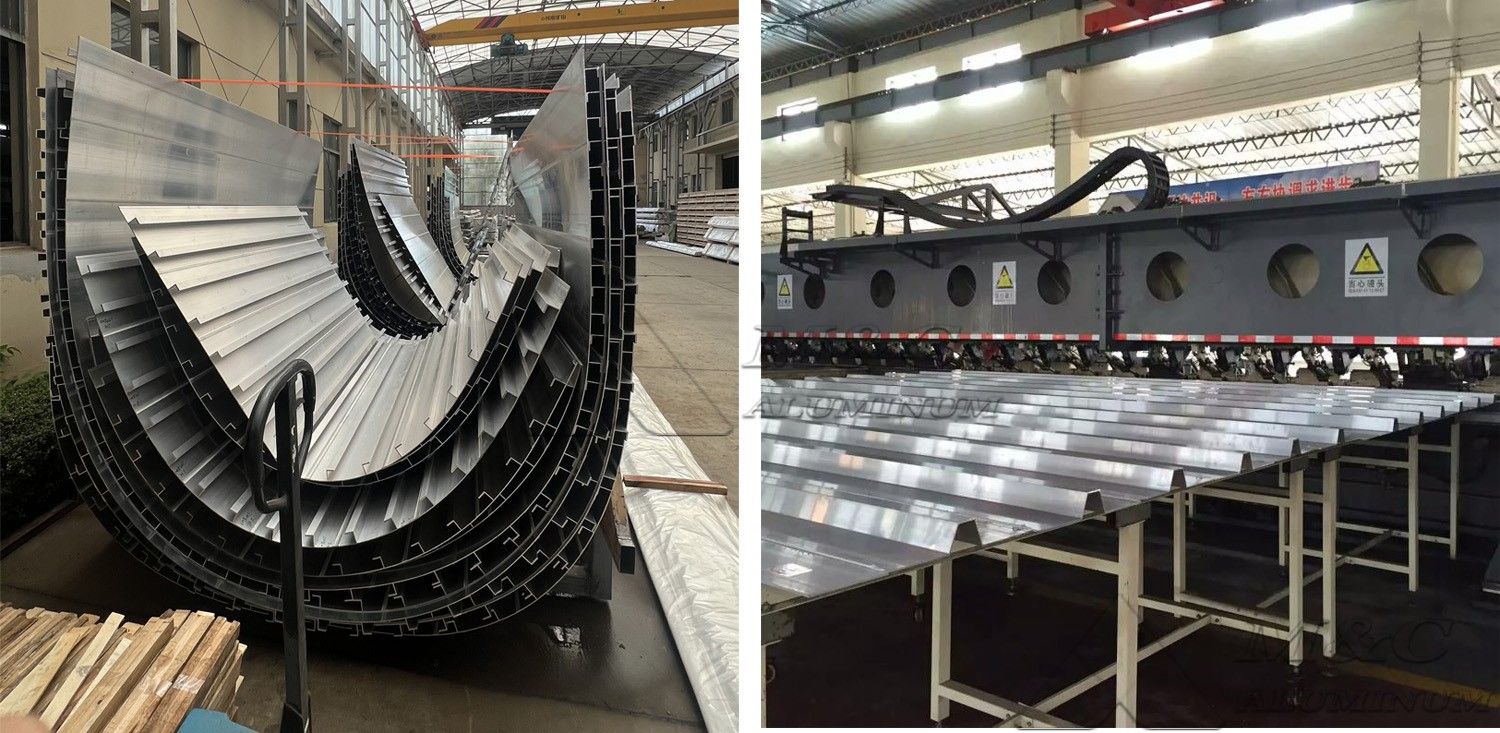

MC Aluminum is equipped with a Friction Stir Welding (FSW) rib-stiffened panel production line, specialized in producing large stiffened panels with a width of 3-4 meters and a length of up to 20 meters. These panels are widely used in rescue vessels, missile fast boats, frigates, destroyers, as well as fisheries patrol boats, marine surveillance ships, and luxury yachts.

What Are Aluminum Stiffened Panels?

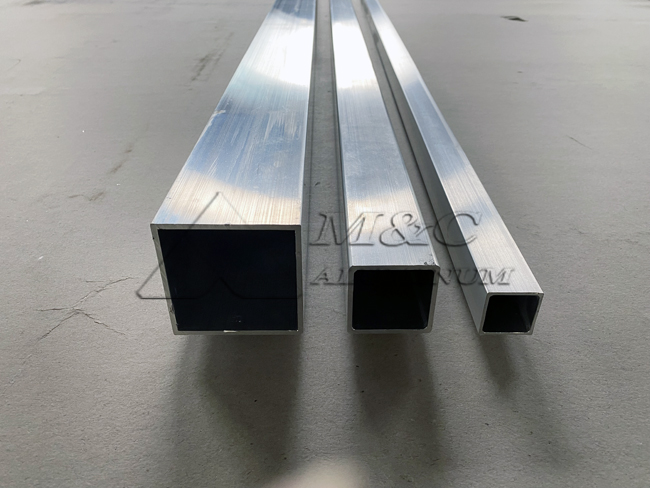

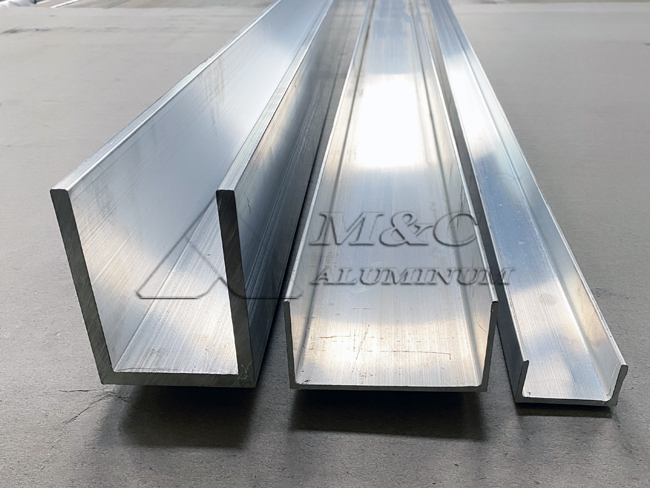

Aluminum reinforced plates are composite panels made by integrating aluminum alloy skins (sheets) with stiffening ribs (profiles) through welding, friction stir welding (FSW), laser welding, and other processes. They are widely used in hull plating, decks, bulkheads, and structures of high-speed vessels, warships, yachts, and ro-ro passenger ferries.

Product Features of Aluminum Stiffened Panels

High Structural Integrity: fewer weld seams, higher stability

Lightweight: reduces unit area weight by 15–25%

Enhanced Stiffness: significantly improved bending and torsional resistance

Excellent Corrosion Resistance: ideal for long-term service in marine environments

Common Aluminum Alloys for Marine Stiffened Panels

Marine stiffened panels mainly use 5xxx-series and 6xxx-series Al-Mg alloys, such as:

5083-H116 / H321: excellent corrosion resistance and weldability, widely used in seawater environments

5383-H116: higher strength and fatigue resistance compared to 5083

5059-H321: high strength and crack resistance, suitable for high-speed naval vessels and special applications

6061-T6 / 6082-T6: heat-treatable alloys with high strength, applied in localized structural components

These alloys combine lightweight properties, corrosion resistance, and weldability, making them ideal for modern shipbuilding.

Why Use Aluminum Stiffened Panels in Ship Hulls?

Compared with traditional marine steels, aluminum stiffened panels offer significant advantages:

1. Extremely Lightweight

The density of aluminum is only about one-third of steel. Using aluminum stiffened panels can reduce the weight of the ship’s superstructure by 50–70%, leading to:

Higher Speed: faster sailing under the same engine power

Increased Payload: more cargo, fuel, or passengers

Lower Fuel Consumption: reduced propulsion resistance and better fuel efficiency, with lower emissions

Improved Stability: lower center of gravity enhances safety and seaworthiness

2. Excellent Corrosion Resistance

Aluminum naturally forms a dense oxide film, which provides strong protection against seawater and marine atmosphere corrosion. Benefits include:

Lower Maintenance Costs: less rust removal and repainting compared with steel ships

Longer Service Life: more durable hull structures

3. Good Weldability and Workability

Modern marine aluminum alloys (5xxx & 6xxx series) have excellent weldability, enabling the construction of complex hull designs.

4. Non-Magnetic Properties

Aluminum’s non-magnetic nature is critical for mine countermeasure vessels and research ships engaged in geomagnetic surveys.

5. Superior Low-Temperature Performance

Aluminum alloys remain ductile at low temperatures, making them ideal for LNG carriers and other cryogenic applications.

Applications of FSW Marine Panels

High-speed RoPax vessels

Using 5083-H116 stiffened panels for hull plating improves speed while reducing fuel consumption.Naval ships

Alloys like 5383 and 5059 are adopted to meet requirements of high strength and protective performance.Luxury yachts

Stiffened deck panels enable large-span spaces with lightweight and aesthetic designs.Offshore engineering

Platforms and floating bridges utilize aluminum stiffened panels for their corrosion resistance and economic maintenance.

Quality Inspection

1. Visual Inspection: check weld seams for smoothness, flatness, and absence of defects

2. Ultrasonic Testing (UT): detect internal weld defects such as porosity, slag inclusions, or cracks

3. Dimensional Accuracy Measurement: ensure panel geometry matches design requirements

4. Mechanical Property Tests: tensile, bending, and hardness tests to verify strength and performance of welds and base metal

Original Source: https://www.marinealum.com/a/hull-stiffeners-mc-aluminum.html

Tag: stiffened panels marine aluminum stiffened panels marine aluminum alloy ribbed panels ribbed panels for ships marine aluminum alloy 5083 marine aluminum stiffened panels 6082-T6 marine-grade aluminum rib panels FSW panel marine FSW panels marine