In the manufacturing of ships and yachts, aluminum extrusions are ubiquitous: railings, ladders, handrails, hatch frames, radar arches, T-top frames, masts, crossbeams, and equipment supports. These components must be lightweight, corrosion-resistant, and capable of withstanding long-term load and harsh marine environments.

Among the various alloys, 6061 and 6063 stand out as the two primary choices for marine equipment extrusions. Both belong to the 6xxx series (Al-Mg-Si) heat-treatable alloys, but they differ in strength, extrusion formability, surface quality, and typical applications.

So the question arises: from railings to masts, how should you choose between 6061 and 6063? This article compares structural performance, machining and surface treatment, corrosion resistance, and typical application logic, providing clear, practical selection guidance.

Advantages of 6000 Series Marine Aluminum

6000 series marine aluminum alloys are widely considered the engineering-grade, versatile choice for ship equipment:

High strength-to-weight ratio: Provides excellent load-bearing capacity while helping reduce weight, improve speed, and enhance fuel efficiency.

Good corrosion resistance: Performs reliably in marine atmospheric environments and is even more durable with anodizing.

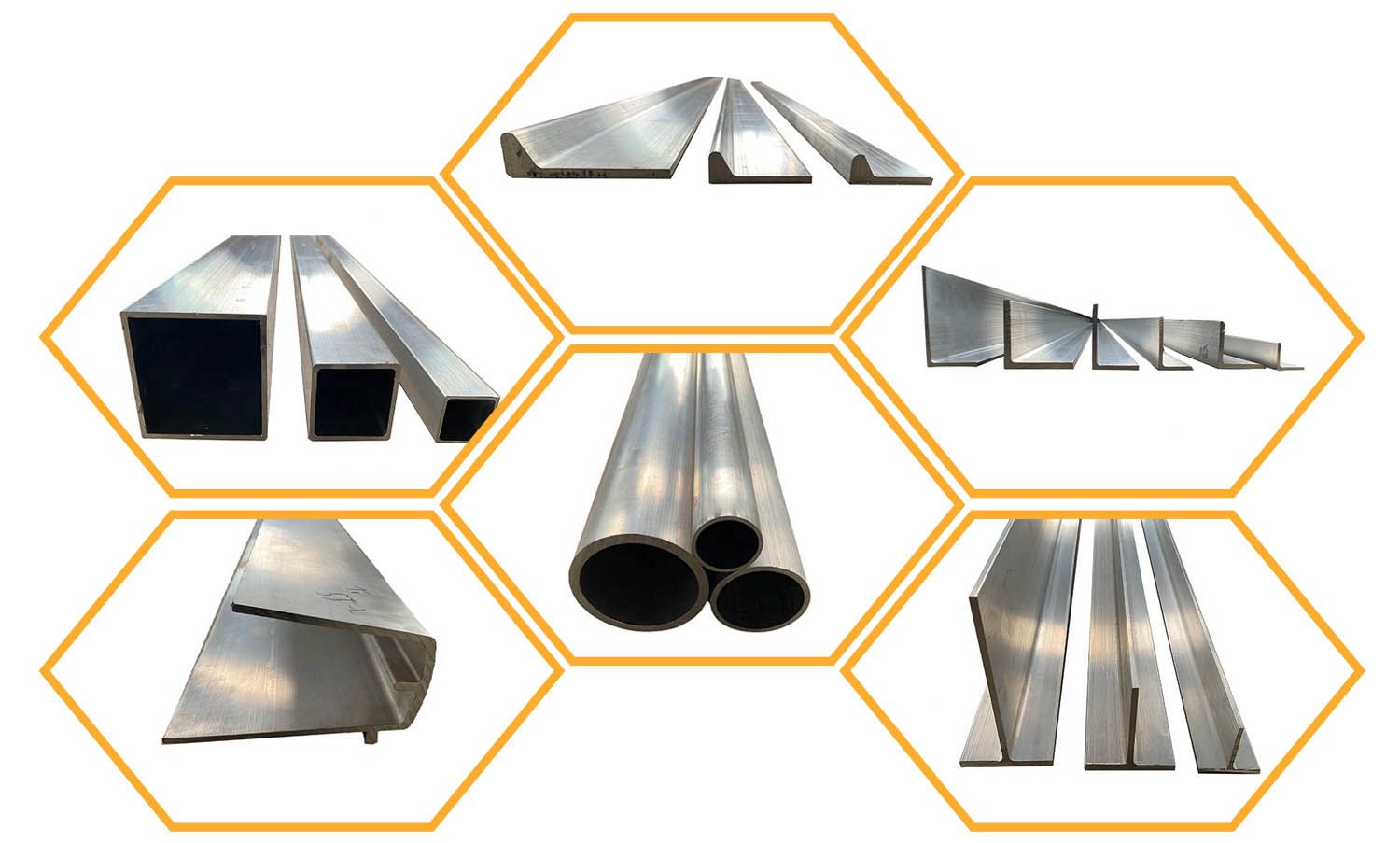

Excellent extrusion performance: Can produce complex cross-sections (reinforcements, hollow sections, slots), facilitating modular assembly.

Good welding and machining adaptability: Supports on-site modifications, maintenance, and fabrication.

6061 vs. 6063 Aluminum Profiles

1. Alloy System and Material Positioning

6061 Marine Aluminum: Known for Structural Strength

6061 is a medium-strength structural alloy, with relatively high magnesium and silicon content and a small amount of copper, giving it excellent mechanical properties in T6 temper. It is primarily used in load-bearing, connecting, and stressed components, aligning with an "engineering structural profile" role.

6063 Marine Aluminum: Known for Extrusion and Surface Finish

6063 has a milder composition, very low copper content, and is optimized for complex extrusions and high surface quality. Called the "king of extrusions", it is ideal for components with high aesthetic requirements, complex sections, and moderate strength needs.

2. Corrosion Resistance

6063 Aluminum: Slightly better resistance to pitting and intergranular corrosion in marine atmospheric environments due to extremely low copper content.

6061 Aluminum: Requires careful surface protection in high-salinity environments if left uncoated.

3. Mechanical Performance

(Reference: common T5/T6 tempers)

| Property | 6061-T6 | 6063-T6 |

| Tensile Strength | ≈ 290 MPa | ≈ 240 MPa |

| Yield Strength | ≈ 240 MPa | ≈ 210 MPa |

| Rigidity & Fatigue Resistance | High | Moderate |

| Welded Strength Retention | Good | Average |

Conclusion:

For masts, load-bearing supports, equipment frames, and structural connections, 6061 offers higher safety margins. 6063 provides sufficient strength for many applications but is not primarily designed for structural load-bearing.

4. Surface Finish

6063 Extrusions:

Fine grain surface

Uniform anodized color

Ideal for natural or hard anodizing, painting, and decorative treatments

6061 Extrusions:

Slightly rougher surface

Minor color variation possible after anodizing

Primarily functional rather than aesthetic

5. Extrusion Performance

6063 has superior extrusion properties: lower deformation resistance, better flow, and easier production of thin and complex sections.

6061 is more difficult to extrude, with higher costs for complex sections, and is better suited for structural or standard profiles.

6. Application Scenarios

Railings and handrails: Frequent human contact requires safety, aesthetics, and corrosion resistance. 6063 is often the better choice.

Masts, support structures, and load-bearing frames: Subjected to significant static and dynamic loads, making 6061 the preferred alloy due to its higher strength and rigidity.

Summary

Under the shipbuilding standards of 2026, green and lightweight design are core trends. As experts in marine aluminum materials, our recommendation is:

"Focus on the essentials, combining strength and flexibility."

For high-stress, critical safety components (such as masts, heavy-duty cranes, and engine room supports), 6061-T6 should be the firm choice, with strict control over welding quality; while for areas with frequent human contact and high aesthetic requirements (such as deck railings, stern cabin decorations, and sunshade frames), 6063 is a more cost-effective and aesthetically pleasing option.

Whether you need high-strength 6061 structural profiles or exquisite and corrosion-resistant 6063 decorative aluminum materials, we can provide you with high-quality products that meet the certifications of international classification societies such as DNV, CCS, and ABS.