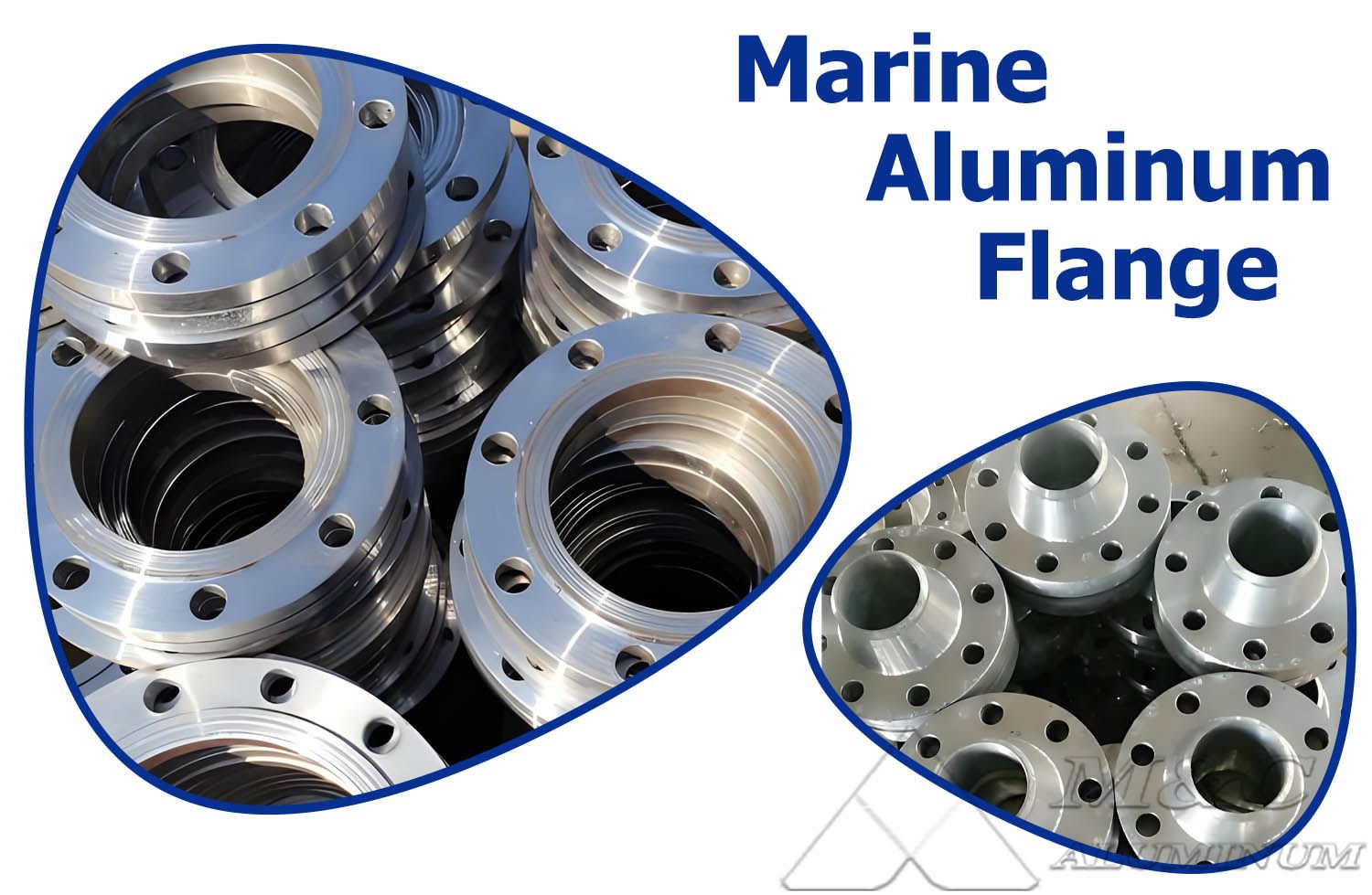

MC Aluminum specializes in the production of marine aluminum flanges, specifically designed for offshore engineering projects, LNG carriers, and high-performance vessels, ensuring outstanding performance even under salt spray corrosion and extreme pressure conditions.

Marine aluminum welding flanges are connection components engineered for aluminum alloy piping systems used in ships and offshore structures. They are typically manufactured from 5xxx series (such as 5083, 5086) or 6xxx series (such as 6061) corrosion-resistant aluminum alloys, produced by forging or casting. These flanges are permanently welded to aluminum pipes, forming strong, reliable, and leak-tight connections.

Why Choose DNV-Certified Aluminum Welding Flanges?

Compared with traditional steel or copper alloy flanges, DNV GL–certified marine aluminum welding flanges offer disruptive advantages across multiple dimensions, perfectly aligning with modern shipbuilding trends toward lightweight design, high efficiency, and environmental sustainability.

1. Significant Lightweight and Energy-Saving Advantages

Aluminum alloys have a density of only about one-third that of steel. A lighter vessel means lower fuel consumption and operating costs, directly improving economic performance and environmental indicators.

2. Outstanding Corrosion Resistance

Aluminum alloys naturally form a dense oxide film, providing excellent resistance to corrosion-especially against seawater and marine atmospheric environments. This significantly reduces maintenance costs, extends pipeline service life, and ensures long-term operational reliability.

3. Excellent Welding Performance

Aluminum welding technology is mature and reliable. Designed specifically for welding connections such as welding neck (WN) and slip-on (SO) flanges, aluminum flanges provide high joint strength and excellent vibration fatigue resistance.

4. Non-Magnetic and Spark-Free Safety

Aluminum alloys are non-magnetic, making them ideal for mine countermeasure vessels and magnetically sensitive ships. Additionally, aluminum does not generate sparks upon impact, making it a safe choice for transporting flammable or explosive fluids.

5. Superior Machinability and Customization

Compatible with a wide range of marine aluminum pipes and standard fittings, aluminum flanges also support custom sizes and structural designs.

6. Environmentally Friendly and Fully Recyclable

Aluminum is a 100% recyclable green metal with a high recycling rate, fully compliant with increasingly stringent environmental regulations and sustainability goals in the global maritime industry.

Performance Comparison

| Comparison Aspect | DNV GL Certified Aluminum Welding Flange | Traditional Steel Flange |

| Material Density | Low (≈ 2.7 g/cm³) | High (≈ 7.85 g/cm³) |

| Weight | Extremely light, significant weight reduction | Heavy |

| Seawater Corrosion Resistance | Excellent, low maintenance | Moderate, requires |

| Life-Cycle Cost | Low (energy-saving, low maintenance) | Medium |

| Environmental & Recyclability | Excellent | Average |

Aluminum Flange Technical Specifications

Material Grades: 5083-H111, 5086-H112, 6061-T6, etc.

Standards: Compliant with DNV GL Rules for Ships / Offshore Standards, and compatible with ASME B16.9, DIN, and related standards

Pressure Ratings: PN6, PN10, PN16, Class 150, Class 300, etc.

Connection Types: Welding Neck (WN), Slip-On (SO)

Size Range: DN15 (1/2") to DN600 (24") or larger

Facing Types: Raised Face (RF), Flat Face (FF)

Surface Treatment: Natural finish, anodizing, or specified protective coatings for enhanced corrosion resistance

Service Environment: Marine and offshore engineering environments

Application Areas of Marine Aluminum Flanges

Ship Piping Systems: Ballast water systems, fire-fighting systems, fuel transfer pipelines

Offshore Platforms: Freshwater and drainage pipelines for drilling platforms and FPSOs

Gas Carriers: Cryogenic piping connections for LNG and LPG vessels

Luxury Yachts: Lightweight piping solutions for aluminum hulls and onboard systems

Why Is DNV GL Certification Critical for Marine Aluminum Flanges?

DNV GL is one of the world's leading classification societies for the maritime and offshore industries. DNV GL certification means that the aluminum flange:

Material Compliance: Chemical composition and mechanical properties fully meet international maritime standards

Strict Manufacturing Control: Production processes are audited by third-party inspectors, ensuring excellent batch consistency

Globally Recognized Market Access: For both new shipbuilding and maintenance projects, DNV GL certification is a "hard currency" for global acceptance, significantly reducing inspection and approval time

FAQ

Q1: What is the significance of DNV GL certification?

A: DNV GL is one of the most authoritative certification bodies in the global maritime industry. Its certification confirms that the flange complies with international ship safety standards and can be directly used in shipbuilding projects.

Q2: What is the difference between aluminum welding flanges and steel flanges?

A: Aluminum flanges are lightweight and corrosion-resistant but are not suitable for high-temperature applications (above 150 °C). Steel flanges offer higher load-bearing capacity but are prone to corrosion and require protective coatings.

Q3: How is the price of marine aluminum welding flanges calculated?

A: Pricing is based on material grade, size, pressure rating, and order quantity. The cost of 5083 aluminum flanges is typically 30-40% lower than that of steel flanges when considering lifecycle cost.

Original Source: https://www.marinealum.com/a/dnv-gl-certified-marine-aluminum-welding-flange.html

Tag: Aluminum flange marine aluminum flange pipeline fittings aluminum alloy flange raised face flange flat face flange marine piping fittings welding neck flange 5083 aluminum flange 6061-T6 aluminum flange 5086 aluminum flange